Abstract

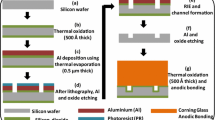

The fabrication technique of DFR using micro channels can form hundreds micro thickness channels with only a photo-lithography process without any etching. Also, DFR is confirmed low consumption power because DFR has very lower thermal conductivity (2.33 W/mK) in comparison with silicon (168 W/mK) therefore displays high performance in heating an internal sample. As DFR is hydrophilic, it can bond with glasses without any treatment. Therefore, anodic bonding process using silicon bulk micromachining or an RIE process used in the PDMS fabrication technique using O2 plasma is not necessary. According to these advantages, it is expected that production cost can be decreased because fabrication costs of the PCR chamber is decreased. In this paper, a soda-lime glass substrate coated with a DFR of the fluid to cycle through different temperature zones was used to form a micro-channel structure and integrated Pt heater continuous-flow PCR.

Similar content being viewed by others

References

Kricka, L.J. Microchips, microarrays, biochips and nanochips: personal laboratories for the 21st century. Clinica Chimica Acta 307, 219–223 (2001).

Lee, J.Y., Kim, J.J. & Park, T.H. Miniaturization of polymerase chain reaction. Biotechnology and Bioprocess Engineering 8, 213–220 (2003).

Schneegass, I. & Köhler, J.M. Flow-through polymerase chain reactions in chip thermocyclers. Reviews in Molecular Biotechnology 82, 101–121 (2001).

Kim, J.A. et al. Fabrication and characterization of a PDMS-glass hybrid continuous-flow PCR chip. Biochemical Engineering Journal 29, 91–97 (2006).

Zhang, C., Xu, J., Ma, W. & Zheng, W. PCR microfluidic devices for DNA amplification. Biotechnology Advance 24, 243–284 (2006).

Singh, J. & Ekaputri, M. PCR thermal management in an integrated lab on chip. Journal of Physics: Conference Series 34, 222–227 (2006).

Kim, K., Park, S.W. & Yang, S.S. The optimization of PDMS-PMMA bonding process using silane primer. BioChip J. 4, 148–154 (1998).

Northrup, M.A., Ching, M.T., White, R.M. & Watson, R.T. DNA amplification with a microfabricated reaction chamber. Proc. 1993 Int. Conf. Solid-State Sens. Actuator 924–926 (1993).

Prakash, A.R. et al. Small volume PCR in PDMS biochips with integrated fluid control and vapour barrier. Sensor and Actuators B 113, 398–409 (2006).

Koukharenko, E., Kraft, M., Ensell, G.J. & Hollinshead, N. A conparative study of different thick photoresists for MEMS applications. Journal of Materials Science L Materials in Electronics 16, 741–747 (2005).

Kukharenka, E., Farooqui, M.M., Grigore, L., Kraft, M. & Hollinshead, N. Electro plating moulds using dry film thick negative photoresist. Jounal of Micromechanics and Microengineering 13, S67–S74 (2003).

Yang, C.R., Hsieh, G.W., Hsieh, Y.S. & Lee, Y.D. Microstructuring characteristics of a chemically amplified photoresist synthesized for ultra-thick UV-LIGA applications. Journal of Micromechanics and Microengineering 14, 1126–1134 (2004).

Schjolberg-Henriksen, K., Jensen, G.U., Hanneborg, A. & Jakobsen, H. Anodic bonding for monolithically integrated MEMS. Sens. Actuators A 114, 332–339 (2004).

Li, Z., Hao, Y., Zhang, D., Li, T. & Wu, G. An SOIMEMS technology using substrate layer and bonded glass as wafer-level package. Sensor and Actuators A 96, 34–42 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, D.Y., Kang, T.W., Seo, C.T. et al. Fabrications of a continuous-flow DNA amplifier using dry film resist. BioChip J 4, 179–183 (2010). https://doi.org/10.1007/s13206-010-4303-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13206-010-4303-9