Abstract

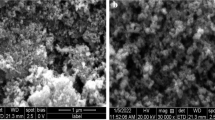

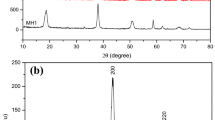

In this study, biodiesel was produced from goat fat in the presence of magnesium oxide (MgO) nano-catalyst using transesterification process. The characteristics of the catalyst were studied using field emission scanning electron microscope (FE-SEM), transmission electron microscope (TEM), Brunauer–Emmett–Teller (BET), energy dispersive X-ray/mapping (EDX/Map), Fourier-transform infrared spectroscopy (FTIR), thermal gravimetric analysis (TGA), and dynamic light scattering (DLS). The result showed that the specific surface area and the average pore diameter of the nanocatalyst were 40.44 m2/g and 36.7 nm, respectively, which showed that the catalyst is mesoporous. According to the results of the DLS analysis, the average particle size of the catalyst was determined to be 5.5 nm. Also, the maximum biodiesel yield of 93.12% was obtained at temperature of 70 °C, methanol/oil molar ratio of 12:1, the catalyst content of 1 wt.%, and reaction time of 3 h. In addition, biodiesel was mixed with diesel at different ratios (B25, B50, B75, and B100) to improve fuel properties of the produced biodiesel. The results indicated that the mixtures of B75 and B100 had better density, viscosity, and flash point in comparison to the other mixtures and their properties were within the range of international standards.

Similar content being viewed by others

References

Agarwal M, Chauhan G, Chaurasia SP, Singh K (2012) Study of catalytic behavior of KOH as homogeneous and heterogeneous catalyst for biodiesel production. J Taiwan Inst Chem Eng 43:89–94

Ali AS, Ahmad F, Farhan M, Ahmad M (2012) Biodiesel production from residual animal fat using various catalysts. Pak J Sci 64:282

Alptekin E, Canakci M (2008) Determination of the density and the viscosities of biodiesel–diesel fuel blends. Renew Energy 33:2623–2630

Altun Ş, Yaşar F, Öner C (2010) The fuel properties of methyl esters produced from canola oil-animal tallow blends by base-catalyzed transesterification. Uluslararası Mühendislik Araştırma ve Geliştirme Dergisi 2:2–5

Anggoro DD, Buchori L, Sasongko SB, AAFF MV (2018) Synthesis of Ca/MgO catalyst using sol gel method for monoglycerides production. AIP Conf Proc 1977:030012

Ashok A, Kennedy LJ, Vijaya JJ, Aruldoss U (2018) Optimization of biodiesel production from waste cooking oil by magnesium oxide nanocatalyst synthesized using coprecipitation method. Clean Technol Environ 20:1219–1231

Azam MM, Waris A, Nahar NM (2005) Prospects and potential of fatty acid methyl esters of some non-traditional seed oils for use as biodiesel in India. Biomass Bioenergy 29:293–302

Banković-Ilić IB, Miladinović MR, Stamenković OS, Veljković VB (2017) Application of nano CaO-based catalysts in biodiesel synthesis. Renew Sust Energy Rev 72:746–760

Baroutian S, Kheireddine Aroua M, Abdul Raman AA, Sulaiman NMN (2008) Estimation of vegetable oil-based ethyl esters biodiesel densities using artificial neural networks. J Appl Sci 8:3005–3011

Canakci M, Ozsezen AN, Arcaklioglu E, Erdil A (2009) Prediction of performance and exhaust emissions of a diesel engine fueled with biodiesel produced from waste frying palm oil. Expert Syst Appl 6:9268–9280

Chakraborty R, Sahu H (2014) Intensification of biodiesel production from waste goat tallow using infrared radiation: process evaluation through response surface methodology and artificial neural network. Appl Energy 114:827–836

Chongkhong S, Tongurai C, Chetpattananondh P (2009) Continuous esterification for biodiesel production from palm fatty acid distillate using economical process. Renew Energy 34:1059–1063

Chouhan AS, Sarma AK (2011) Modern heterogeneous catalysts for biodiesel production: a comprehensive review. Renew Sust Energy Rev 15:4378–4399

Dorado MP, Cruz F, Palomar JM, Lopez FJ (2006) An approach to the economics of two vegetable oil-based biofuels in Spain. Renew Energy 31:1231–1237

Enweremadu CC, Mbarawa MM (2009) Technical aspects of production and analysis of biodiesel from used cooking oil—a review. Renew Sust Energy Rev 13:2205–2224

Esmaeili H, Foroutan R (2018) Optimization of biodiesel production from goat tallow using alkaline catalysts and combining them with diesel. Chem Chem Technol 12:120–126

Gürü M, Koca A, Can Ö, Çınar C, Şahin F (2010) Biodiesel production from waste chicken fat based sources and evaluation with Mg based additive in a diesel engine. Renew Energy 35:637–643

Hara M (2009) Environmentally benign production of biodiesel using heterogeneous catalysts. ChemSusChem Chem Sust Energy Mater 2:129–135

Jung HS, Lee JK, Kim JY, Hong KS (2003) Crystallization behaviors of nanosized MgO particles from magnesium alkoxides. J Coll Interface Sci 259:127–132

Keihani M, Esmaeili H, Rouhi P (2018) Biodiesel production from chicken fat using nano-calcium oxide catalyst and improving the fuel properties via blending with diesel. Phys Chem Res 6:521–529

Krishna K, Kumar BSP, Reddy KVK, Kumar SC, Kumar KR (2017) Effects of alumina nano metal oxide blended palm stearin methyl ester bio-diesel on direct injection diesel engine performance and emissions. IOP Conf Ser Mater Sci Eng 225:012212

Li Y, Qiu F, Yang D, Li X, Sun P (2011) Preparation, characterization and application of heterogeneous solid base catalyst for biodiesel production from soybean oil. Biomass Bioenergy 35:2787–2795

Liu K, Wang R (2013) Biodiesel production by transesterification of duck oil with methanol in the presence of alkali catalyst. Pet Coal 55(1):68–72

Liu C, Lv P, Yuan Z, Yan F, Luo W (2010) The nanometer magnetic solid base catalyst for production of biodiesel. Renew Energy 35:1531–1536

Lukić I, Krstić J, Jovanović D, Skala D (2009) Alumina/silica supported K2CO3 as a catalyst for biodiesel synthesis from sunflower oil. Bioresour Technol 100:4690–4696

Luu PD, Takenaka N, Van Luu B, Pham LN, Imamura K, Maeda Y (2014) Co-solvent method produce biodiesel form waste cooking oil with small pilot plant. Energy Procedia 61:2822–2832

Ma Y, Wang Q, Gao Z, Sun X, Wang N, Niu R, Ma H (2016) Transesterification of waste cooking oil using FeCl3-modified resin catalyst and the research of catalytic mechanism. Renew Energy 86:643–650

Marulanda VF, Anitescu G, Tavlarides LL (2010) Investigations on supercritical transesterification of chicken fat for biodiesel production from low-cost lipid feedstocks. J Supercrit Fluid 54:53–60

Math MC (2016) Application of response surface methodology for optimization of biodiesel production by transesterification of animal fat with methanol. Int J Renew Energy Res 6:74–79

Mguni LL (2012) Biodiesel production over supported nano-magnesium oxide particles. Doctoral dissertation, University of Johannesburg

Moser BR (2009) Biodiesel production, properties, and feedstocks. Vitro Cell Dev Biol Plant 45:229–266

Obadiah A, Swaroopa GA, Kumar SV, Jeganathan KR, Ramasubbu A (2012) Biodiesel production from palm oil using calcined waste animal bone as catalyst. Bioresour Technol 116:512–516

Okitsu K, Sadanaga Y, Takenaka N, Maeda Y, Bandow H (2013) A new co-solvent method for the green production of biodiesel fuel—optimization and practical application. Fuel 103:742–748

Ramadhas AS, Jayaraj S, Muraleedharan C (2005) Biodiesel production from high FFA rubber seed oil. Fuel 84:335–340

Rao PV (2011) Experimental investigations on the influence of properties of jatropha biodiesel on performance, combustion, and emission characteristics of a DI-CI engine. World Acad Sci Eng Technol 75:855–868

Rodríguez-Guerrero JK, Rosa PT (2013) Production of biodiesel from castor oil using sub and supercritical ethanol: effect of sodium hydroxide on the ethyl ester production. J Supercrit Fluid 83:124–132

Seffati K, Honarvar B, Esmaeili H, Esfandiari N (2019) Enhanced biodiesel production from chicken fat using CaO/CuFe2O4 nanocatalyst and its combination with diesel to improve fuel properties. Fuel 235:1238–1244

Srivastava A, Prasad R (2000) Triglycerides-based diesel fuels. Renew Sust Energy Rev 4:111–133

Tate RE, Watts KC, Allen CAW, Wilkie KI (2006) The densities of three biodiesel fuels at temperatures up to 300 °C. Fuel 85:1004–1009

Vasudevan PT, Briggs M (2008) Biodiesel production—current state of the art and challenges. J Ind Microbiol Biotechnol 35:421

Viriya-Empikul N, Krasae P, Puttasawat B, Yoosuk B, Chollacoop N, Faungnawakij K (2010) Waste shells of mollusk and egg as biodiesel production catalysts. Bioresour Technol 101:3765–3767

Yacob AR, Mustajab MKAA, Samadi NS (2009) Calcination temperature of nano MgO effect on base transesterification of palm oil. World Acad Sci Eng Technol 56:408–412

Yin JZ, Ma Z, Hu DP, Xiu ZL, Wang TH (2010) Biodiesel production from subcritical methanol transesterification of soybean oil with sodium silicate. Energy Fuel 24:3179–3182

Zhang Y, Dube MA, McLean DDL, Kates M (2003) Biodiesel production from waste cooking oil: 1. Process design and technological assessment. Bioresour Technol 89:1–16

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Rasouli, H., Esmaeili, H. Characterization of MgO nanocatalyst to produce biodiesel from goat fat using transesterification process. 3 Biotech 9, 429 (2019). https://doi.org/10.1007/s13205-019-1963-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-019-1963-6