Abstract

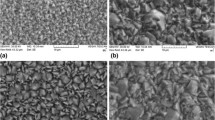

In the present work, the surface properties of EN8 steel with/without pulse electrodeposition have been investigated. The co-deposition of nano-sized Yttria Stabilized Zirconia (YSZ; ≈ 80 nm average diameter) has been done using additive—free nickel solution by applying the pulse current. The deposition of YSZ-Ni metal matrix composite (MMC) was obtained by varying the duty cycle (D.C.; i.e. 30 and 50%) and maintaining a constant frequency of 10 Hz. The current density also varied between 0.02 and 0.06 A/cm2 and optimized on the basis of improvement of surface characteristics and defect-free deposits. Penetration strength of the composite coated surface has been investigated with the nanoindentation test. A significant difference in the surface hardness was observed by varying the duty cycles and current densities. Corrosion test has been performed to estimate the corrosion rate of the coated surfaces. And, it observed approximately one-fourth times reduction in corrosion rate for MMC electrocoating at the optimum condition as compared to the base substrate. In addition, the adherence quality and antiwear performance of different coated substrates evaluated with reciprocating test rig. A substantial improvement in antiwear performance for composite coatings has been reported. Different analytical tools have been used to characterize the composite surfaces. Also, the effects of various process controlling parameters and corresponding analysis have been reported.

Similar content being viewed by others

References

Ahmad Z (2006) Coatings (Chapter 7). Principle of corrosion engineering and corrosion control, pp 382–437. Butterworth-Heinemann Publication, Oxford, UK

Alexandridou S, Kiparissedes C, Fransaer J, Celis JP (1995) On the synthesis of oil-containing microcapsules and their electrolytic codeposition. Surf Coat Technol 71(3):267–276

Aruna ST, Rajam KS (2003) Synthesis, characterisation and properties of Ni/PSZ and Ni/YSZ nanocomposites. Scripta Mater 48:507–512

ASTM G133, Reapproved (2016) Linearly reciprocating ball-on-flat sliding wear. ASTM International, West Conshohocken, PA

Bahrololoom ME, Sani R (2005) The influence of pulse plating parameters on the hardness and wear resistance of nickel–alumina composite coatings. Surf Coat Technol 192:154–163

Baosong L, Weiwei Z, Tianyong M, Shengsong D, Yicheng M, Dandan L (2020) Synthesis and properties of YSZ and CeO2 dual nanoparticles doped Ni–B matrix nanocomposite coating. Ceram Int 46:8047–8058

Bełtowska-lehman E, Góral A, Indyka P (2011) Electrodeposition and characterization of Ni/Al2O3nanocomposite coatings. Arch Metall Mater 56(4):919–931

Chandrasekar MS, Pushpavanam M (2008) Pulse and pulse reverse plating- conceptual, advantages and applications. Electrochim Acta 53:3313–3322

Ghazanlou SI, Farhood AHS, Hosouli S, Ahmadiyeh S, Rasooli A (2017) Pulse frequency and duty cycle effects on the electrodeposited Ni–Co reinforced with micro and nano-sized ZnO. J Mater Sci: Mater Electron 28:15537–15551

Góral A (2017) Nanoscale structural defects in electrodeposited Ni/Al2O3 composite coatings. Surf Coat Technol 319:23–32

Gupta RN, Das AK, Shah H, Nagahanumaiah (2016) Pulse electrocodeposited Ni–WC composite coating. Mater Manuf Processes 31:42–47

Gyawali G, Tripathi K, Joshi B, Lee SW (2017) Mechanical and tribological properties of Ni-W-TiB2 composite coatings. J Alloy Compd 721:757–763

Hainsworth HV, Chandler HW, Page TF (1996) Analysis of nanoindentation load-displacement loading curves. J Mater Res 11(8):1987–1995

Hou Z, Xiong L, Liu Y, Zhu L, Li W (2019) Preparation of super-aligned carbon nanotube-reinforced nickel-matrix laminar composites with excellent mechanical properties. Int J Miner Metall Mater 26(1):133–141

Ibañez A, Fatás E (2005) Mechanical and structural properties of electrodeposited copper and their relation with the electrodeposition parameters. Surf Coat Technol 191:7–16

Jeerapan T, Casey RT, Nandika D, Adel M, Teresa DG (2013) Influence of bath composition at acidic pH on electrodeposition of nickel-layered silicate nanocomposites for corrosion protection. Int J Electrochem. https://doi.org/10.1155/2013/853869

Kasturibai S, Kalaignan GP (2013) Physical and electrochemical characterizations of Ni-SiO2 nanocomposite coatings. Ionics 19:763–770

Lai L, Li H, Sun Y, Ding G, Wang H, Yang Z (2019) Investigation of electrodeposition external conditions on morphology and texture of Ni/SiCw composite coatings. Appl Sci 9:3024

Lamnini S, Károly Z, Bódis E, Balázsi K, Balázsi C (2019) Influence of structure on the hardness and the toughening mechanism of the sintered 8YSZ/MWCNTs composites. Ceram Int 45:5058–5065

Musil J (2012) Hard nanocomposite coatings: thermal stability, oxidation resistance and toughness. Surf Coat Technol 207:50–65

Peter O, Popoola P, Popoola OM, Delport DJ (2016) Parametric variables in electro-deposition of composite coatings. Golden electrodeposition of composite materials. Adel M, Mohamed A, and Teresa D 10.5772/62010

Prajapati AK, Omrani E, Menezes PL, Rohatgi PL (2018) Fundamentals of solid lubricants. Self-lubricating composites, Springer, Berlin

Praveen Kumar CM, Venkatesha TV, Shabadi R (2013) Preparation and corrosion behavior of Ni and Ni-graphene composite coatings. Mater Res Bull 48:1477–1483

Rudnik E, Syrek S (2014) Studies on the codeposition of SiC nanopowder with nickel, cobalt, and Co-Ni alloys. J Coat 2014:1–10

Sierra-Herrera DK, Sandoval-Amador A, Montañez-Supelano ND, Peña-Ballesteros DY (2017) The effect of pulsed current electrodeposition parameters of calcium phosphates coating on Ti6Al4V ELI. J Phys Conf Series 935:012032

Singh VB, Singh DK (2014) An overview on the preparation, characterization and properties of electrodeposited-metal matrix nanocomposites. Nanosci Technol 1(3):1–20

Singh AK, Adstedt K, Brown B, Singh PM, Graham S (2019) Development of ALD coatings for harsh environment applications. ACS Appl Mater Interfaces 11(7):7498–7509

Walsh FC, León CP (2014) A review of the electrodeposition of metal matrix composite coatings by inclusion of particles in a metal layer: an established and diversifying technology. Transactions Instit Met Finish 92(2):83–98

Yao Y, Yao S, Zhang L, Wang H (2007) Electrodeposition and mechanical and corrosion resistance properties of Ni–W/SiC nanocomposite coatings. Mater Lett 61(1):67–70

Zhou Y, Xie FQ, Wu XQ, Zhao WD, Chen X (2017) A novel plating apparatus for electrodeposition of Ni-SiC composite coatings using circulating-solution co-deposition technique. J Alloy Compd 699:366–377

Acknowledgements

The author is thankful to Micro System Technology Lab, Central Mechanical Engineering Research Institute, Durgapur for providing pulse coating facility. The author would also like to express his sincere gratitude to Dr. A.K.Das, Indian Institute of Technology (Indian School of Mines), Dhanbad for his continuous support and guidance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, R.N. Study of pulse electrodeposition parameters for nano YSZ-Ni coatings and its effect on tribological and corrosion characteristics. Appl Nanosci 11, 173–185 (2021). https://doi.org/10.1007/s13204-020-01567-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-020-01567-9