Abstract

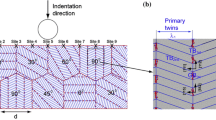

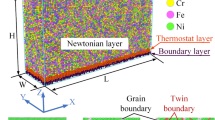

The processes of nanoindentation on Hastelloy alloy with nanoscale twin boundary (TB) are calculated by molecular dynamics (MD). The effect of nanoscale TB’s thickness on the mechanical properties are investigated. The results show that the thickness of nanoscale TBs has obvious influence on the properties of Hastelloy alloy. The TBs obviously play the role of obstacle when the crystal lattice was destroyed by the force of indenter. Although the nanoscale twin boundaries can resist the movement to a certain extent, it does not mean that the thicker nanoscale TBs make the properties better. In these simulations, the Hall–Petch effect and the reverse Hall–Petch effect are observed, and the critical value of thickness is 25.493 Å.

Similar content being viewed by others

References

Chen M, Ma E, Hemker KJ, Sheng H, Wang Y, Cheng X (2003) Deformation twinning in nanocrystalline aluminum. Science 300(5623):1275–1277

Chen K, Wu W, Liao C, Chen L, Tu K (2008) Observation of atomic diffusion at twin-modified grain boundaries in copper. Science 321(5892):1066–1069

Cui J, Zhang Z, Jiang H et al (2019a) Ultrahigh recovery of fracture strength on mismatched fractured amorphous surfaces of silicon carbide. ACS Nano 13(7):7483–7492

Cui J, Zhang Z, Liu D et al (2019b) Unprecedented piezoresistance coefficient in strained silicon carbide. Nano Lett 19(9):6569–6576

Edalati K, Toh S, Furuta T, Kuramoto S, Watanabe M, Horita Z (2012) Development of ultrahigh strength and high ductility in nanostructured iron alloys with lattice softening and nanotwins. Scr Mater 67(5):511–514

Gandhi VCS, Ramesh S, Kumaravelan R (2012) Evaluation of the contact parameters of a structural rigid sphere and a deformable flat contact model by considering the strain hardening effect. J Eng Technol 2(2):97

Kobler A, Beuth T, Klöffel T, Prang R, Moosmann M, Scherer T, Walheim S, Hahn H, Kübel C, Meyer B (2015) Nanotwinned silver nanowires: structure and mechanical properties. Acta Mater 92(15):299–308

Lu L, Shen Y, Chen X, Qian L, Lu K (2004) Ultrahigh strength and high electrical conductivity in copper. Science 304(5669):422–426

Lu L, Schwaige R, Shan Z, Dao M, Lu K, Suresh S (2005) Nano-sized twins induce high rate sensitivity of flow stress in pure copper. Acta Mater 53(7):2169–2179

Lu K, Lu L, Suresh S (2009a) Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 324(5925):349–352

Lu L, Chen X, Huang X, Lu K (2009b) Revealing the maximum strength in nanotwinned copper. Science 323(5914):607–610

Luo X, Zhu X, Zhang G (2014) Nanotwin-assisted grain growth in nanocrystalline gold films under cyclic loading. Nat Commun 5(5):3021

Shaw LL, Tian J, Ortiz AL, Dai K, Villegas JC, Liaw PK, Ren R, Klarstrom DL (2010) A direct comparison in the fatigue resistance enhanced by surface severe plastic deformation and shot peening in a C-2000 superalloy. Mater Sci Eng A 527(4–5):986–994

Wang B, Zhang Z, Cui J, Jiang N (2017) In situ TEM study of interaction between dislocations and a single nanotwin under nanoindentation. ACS Appl Mater Inter 9:29451–29456

Wang B, Zhang Z, Chang K et al (2018) New deformation-induced nanostructure in silicon. Nano Lett 18(7):4611–4617

Wu Y, Adams GG (2009) Plastic yield conditions for adhesive contacts between a rigid sphere and an elastic half-space. J Tribol 131(1):011403–011409

Zhang Y, Tao NR, Lu K (2008) Mechanical properties and rolling behaviors of nano-grained copper with embedded nano-twin bundles. Acta Mater 56(11):2429–2440

Zhang Z, Song Y, Xu C et al (2012a) A novel model for undeformed nanometer chips of soft-brittle HgCdTe films induced by ultrafine diamond grits. Scripta Mater 67(2):197–200

Zhang Z, Huo F, Zhang X et al (2012b) Fabrication and size prediction of crystalline nanoparticles of silicon induced by nanogrinding with ultrafine diamond grits. Scripta Mater 67(7–8):657–660

Zhang Z, Huo Y, Huo F et al (2013a) Ultrahigh hardness and synergistic mechanism of a nanotwinned structure of cadmium zinc telluride. Scripta Mater 68(9):747–750

Zhang Z, Li F, Ma G et al (2013b) Ultrahigh hardness and improved ductility for nanotwinned mercury cadmium telluride. Scripta Mater 69(3):231–234

Zhang Z, Bo W, Zhang X (2014) A maximum in the hardness of nanotwinned cadmium telluride. Scr Mater 72–73(2):39–42

Zhang Z, Wang B, Kang R et al (2015a) Changes in surface layer of silicon wafers from diamond scratching. CIRP Ann Manuf Technol 64(1):349–352

Zhang Z, Guo D, Wang B et al (2015b) A novel approach of high speed scratching on silicon wafers at nanoscale depths of cut. Sci Rep 5:16395

Zhang Z, Huang S, Chen L, Wang B, Wen B, Zhang B, Guo D (2017) Ultrahigh hardness on a face-centered cubic metal. Appl Surf Sci 416:891–900

Zhu T, Li J, Samanta A, Kim HG, Subra S (2007) Interfacial plasticity governs strain rate sensitivity and ductility in nanostructured metals. Proc Natl Acad Sci USA 104(9):3031–3036

Zhu Y, Liao X, Wu X (2012) Deformation twinning in nanocrystalline materials. Prog Mater Sci 57(1):1–62

Acknowledgements

The authors acknowledge for the financial support from the Fundamental Research for the Central Universities (DUT16QY46).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, H., Guo, M., Wang, L. et al. Effect of thickness for nanotwins on the mechanical properties of a Hastelloy. Appl Nanosci 10, 1475–1480 (2020). https://doi.org/10.1007/s13204-019-01209-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-019-01209-9