Abstract

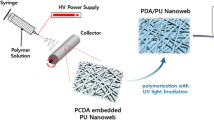

Herein, we first time present our research on ultrasonic dyeing of polyurethane (PU) nanofibers. The PU nanofibers were fabricated by electrospinning process and were subsequently dyed following exhaust method using sonication. The two disperse dyes selected were a low-energy disperse dye (CI Disperse Blue 56) and a high-energy disperse dye (CI Disperse Red 167:1). The ultrasonic energy was used to achieve higher color build-up on PU nanofibers. The temperature/time (T/T) diagram of proposed dyeing process has been suggested; dyeing time and dyeing temperature were optimized. Color build-up properties (measured in terms of K/S values), dye fixation (%), and color fastness properties were studied in detail. The samples were characterized by scanning electron microscope (SEM), Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), and mechanical strength measurements. The results show 70 °C and 40 min as optimum dyeing temperature and time, respectively. The SEM, FTIR, and XRD results did not show any significant effect of ultrasonic dyeing on morphology, chemical, and crystallographic structure of PU nanofibers. Color fastness results revealed excellent light fastness, very good washing, and hot pressing fastness of both dyes.

Similar content being viewed by others

References

Almasian A, Chizari Fard G, Parvinzadeh Gashti M, Mirjalili M, Mokhtari Shourijeh Z (2016) Surface modification of electrospun PAN nanofibers by amine compounds for adsorption of anionic dyes. Desalination Water Treat 57(22):10333–10348

Bandara T, Weerasinghe A, Dissanayake M, Senadeera G, Furlani M, Albinsson I (2018) Characterization of poly (vinylidene fluoride-co-hexafluoropropylene)(PVdF-HFP) nanofiber membrane based quasi solid electrolytes and their application in a dye sensitized solar cell. Electrochim Acta 266:276–283

Burkinshaw S, Jeong D (2008) The clearing of poly (lactic acid) fibres dyed with disperse dyes using ultrasound. Part 1: Colorimetric analysis. Dyes Pigm 77(1):171–179

Burkinshaw SM, Salihu G (2017) The role of auxiliaries in the immersion dyeing of textile fibres: Part 11 residual inorganic electrolyte levels present during the wash-off of commercial grade reactive dyes. Dyes Pigm. https://doi.org/10.1016/j.dyepig.2017.12.006

Chen TK, Tien YI, Wei KH (2000) Synthesis and characterization of novel segmented polyurethane/clay nanocomposites. Polymer 41(4):1345–1353

Darko G, Goethals A, Torto N, De Clerck K (2016) Steady state electrospinning of uniform polyethersulfone nanofibers using a non-heated solvent mixture. Appl Nanosci 6(6):837–845

Fantini D, Costa L (2009) Dye, fluorophores and pigment coloration of nanofibers produced by electrospinning. Polym Adv Technol 20(2):111–121

Gopiraman M, Deng D, Saravanamoorthy S, Chung I-M, Kim IS (2018) Gold, silver and nickel nanoparticle anchored cellulose nanofiber composites as highly active catalysts for the rapid and selective reduction of nitrophenols in water. RSC Adv 8(6):3014–3023

Gumber K, Sidhu A, Kaur R (2017) Sonochemical synthesis of novel magnesium 1, 2, 4-triazole-1-carbodithioate nanoparticles as antifungals. Appl Nanosci 7(3–4):95–100

Gupta KC, Haider A, Choi Y-r, Kang I-k (2014) Nanofibrous scaffolds in biomedical applications. Biomater Res 18(1):5

Harilal M, Krishnan G, Pal S, Reddy B, Ab Rahim MV, Yusoff MH, M. M (2018) Environment-modulated crystallization of Cu2O and CuO nanowires by electrospinning and their charge storage properties. Langmuir 34(5):1873–1882

Horrocks AR, Anand SC (2000). Handbook of technical textiles. Elsevier, New York

Jatoi AW, Ahmed F, Khatri M, Tanwari A, Khatri Z, Lee H (2017) Ultrasonic-assisted dyeing of Nylon-6 nanofibers. Ultrason Sonochem 39:34–38

Jatoi AW, Jo YK, Lee H, Oh SG, Hwang DS, Khatri Z (2018) Antibacterial efficacy of poly (vinyl alcohol) composite nanofibers embedded with silver-anchored silica nanoparticles. J Biomed Mater Res Part B Appl Biomater 106B(3):1121–1128

Jiang H, Zhang L, Cai J, Ren J, Cui Z, Chen W (2018). Quinoidal bithiophene as disperse dye: substituent effect on dyeing performance. Dyes Pigm

Ke M, Wahab JA, Hyunsik B, Song K-H, Lee JS, Gopiraman M (2016) Allantoin-loaded porous silica nanoparticles/polycaprolactone nanofiber composites: fabrication, characterization, and drug release properties. RSC Adv 6(6):4593–4600

Khatri Z, Arain RA, Jatoi AW, Mayakrishnan G, Wei K, Kim I-S (2013a) Dyeing and characterization of cellulose nanofibers to improve color yields by dual padding method. Cellulose 20(3):1469–1476

Khatri Z, Mayakrishnan G, Hirata Y, Wei K, Kim I-S (2013b) Cationic-cellulose nanofibers: preparation and dyeability with anionic reactive dyes for apparel application. Carbohydr Polym 91(1):434–443

Khatri A, Ali S, Jhatial AK, Kim SH (2015) Dyeability of polyurethane nanofibres with disperse dyes. Color Technol 131(5):374–378

Khatri M, Ahmed F, Jatoi AW, Mahar RB, Khatri Z, Kim IS (2016) Ultrasonic dyeing of cellulose nanofibers. Ultrason Sonochem 31:350–354

Lee S, Kim B (2009) High solid and high stability waterborne polyurethanes via ionic groups in soft segments and chain termini. J Colloid Interface Sci 336(1):208–214

Lee H, Jatoi AW, Kyohei Y, Kim K-O, Song KH, Lee J (2018) Deodorant activity of phthalocyanine complex nanofiber. Text Res J 88(6):630–635

Li D, Xia Y (2003) Fabrication of titania nanofibers by electrospinning. Nano Lett 3(4):555–560

Mallakpour S (2018) Ultrasonic-assisted fabrication of starch/MWCNT-glucose nanocomposites for drug delivery. Ultrason Sonochem 40:402–409

McCune D, Guo X, Shi T, Stealey S, Antrobus R, Kaltchev M (2018) Electrospinning pectin-based nanofibers: a parametric and cross-linker study. Appl Nanosci 8(1–2):33–40

Moholkar VS, Warmoeskerken MM, Ohl CD, Prosperetti A (2004) Mechanism of mass-transfer enhancement in textiles by ultrasound. AIChE J 50(1):58–64

Nirmala R, Kalpana D, Navamathavan R, Lee YS, Kim HY (2013) Preparation and characterizations of silver incorporated polyurethane composite nanofibers via electrospinning for biomedical applications. J Nanosci Nanotechnol 13(7):4686–4693

Pang C, Lee G-Y, Kim T-i, Kim SM, Kim HN, Ahn S-H (2012) A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat Mater 11(9):795

Park M, Rabbani MM, Shin HK, Park S-J, Kim HY (2016) Dyeing of electrospun nylon 6 nanofibers with reactive dyes using electron beam irradiation. J Ind Eng Chem 39:16–20

Randall D, Lee S (2002) The polyurethane book. Wilely, New York

Salama A, Mohamed A, Aboamera NM, Osman T, Khattab A (2018) Photocatalytic degradation of organic dyes using composite nanofibers under UV irradiation. Appl Nanosci 8(1–2):155–161

Shore J (1995) Cellulosics dyeing. Society of Dyers and Colourists, Bradford, West Yorkshire, UK

Srivastava A, Srivastava O, Talapatra S, Vajtai R, Ajayan P (2004) Carbon nanotube filters. Nat Mater 3(9):610

Starczak R, Wąs-Gubała J (2016) UV–Vis microspectrophotometric study of wool and polyamide fibres dyed with analogous gryfalan dyes. Dyes Pigm 132:58–63

Suresh K, Kumar RV, Kumar M, Jeyapriya M, Anbarasan R, Pugazhenthi G (2017) Sonication-assisted synthesis of polystyrene (PS)/organoclay nanocomposites: influence of clay content. Appl Nanosci 7(5):215–223

Tang B, Yao Y, Chen W, Chen X, Zou F, Wang X (2018) Kinetics of dyeing natural protein fibers with silver nanoparticles. Dyes Pigm 148:224–235

Tissera ND, Wijesena RN, de Silva KN (2016) Ultrasound energy to accelerate dye uptake and dye–fiber interaction of reactive dye on knitted cotton fabric at low temperatures. Ultrason Sonochem 29:270–278

Tomić T, Babić S, Biošić M, Nasipak NU, Čižmek A-M (2018) Determination of the Solvent Blue 35 dye in diesel fuel by solid phase extraction and high-performance liquid chromatography with ultraviolet detection. Dyes Pigm 150:216–222

Unnithan AR, Gnanasekaran G, Sathishkumar Y, Lee YS, Kim CS (2014) Electrospun antibacterial polyurethane–cellulose acetate–zein composite mats for wound dressing. Carbohydr Polym 102:884–892

Veerabhadraiah A, Ramakrishna S, Angadi G, Venkatram M, Ananthapadmanabha VK, NarayanaRao NMH (2017) Development of polyvinyl acetate thin films by electrospinning for sensor applications. Appl Nanosci 7(7):355–363

Wahab JA, Xu G, Lee H, Nam PD, Wei K, Kim SH (2016) Fabrication of silk fibroin/eggshell nanofiber membranes for facemasks. Fibers Polym 17(11):1776–1781

Wahab JA, Lee H, Wei K, Nagaishi T, Khatri Z, Behera BK (2017) Post-electrospinning thermal treatments on poly (4-methyl-1-pentene) nanofiber membranes for improved mechanical properties. Polym Bull 74(12):5221–5230

Wang HH, Chen KV (2007) A novel synthesis of reactive nano-clay polyurethane and its physical and dyeing properties. J Appl Polym Sci 105(3):1581–1590

Wojciechowski K (1996) Halochromic effects of azophthalimide dyes and their prediction by PPP method. Dyes Pigm 32(4):199–208

Yang H, Xu H, Li M, Zhang L, Huang Y, Hu X (2016) Assembly of NiO/Ni (OH) 2/PEDOT nanocomposites on contra wires for fiber-shaped flexible asymmetric supercapacitors. ACS Appl Mater Interfaces 8(3):1774–1779

Yin C, Jatoi A, Bang H, Gopiraman M, Kim I-S (2016) Fabrication of silk fibroin based three dimensional scaffolds for tissue engineering. Fibers Polym 17(8):1140–1145

Yoo HJ, Mahapatra SS, Cho JW (2014) High-speed actuation and mechanical properties of graphene-incorporated shape memory polyurethane nanofibers. J Phys Chem C 118(19):10408–10415

Zhuo H, Hu J, Chen S, Yeung L (2008) Preparation of polyurethane nanofibers by electrospinning. J Appl Polym Sci 109(1):406–411

Acknowledgements

We are thankful to Japanese Government Scholarship (Monbukagakusho: MEXT) program for financial support in the project. We pay our sincere thanks to Nanomaterials Research Group, Department of Textile Engineering, Mehran University of Engineering and Technology, Jamshoro 76062, Pakistan, for color fastness tests.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All the authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jatoi, A., Kim, I.S. & Ni, QQ. Ultrasonic energy-assisted coloration of polyurethane nanofibers. Appl Nanosci 8, 1505–1514 (2018). https://doi.org/10.1007/s13204-018-0823-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-018-0823-8