Abstract

A crumpled graphene oxide–SnO2 nanocolumn (CGO–SnO2) composite electrode was fabricated using aerosol-based techniques. First, SnO2 nanocolumn thin films were fabricated using an aerosol chemical vapor deposition (ACVD) technique. The surface of the nanocolumn was then decorated with CGO by electrospray deposition. The CGO–SnO2 electrode was utilized for the electrochemical detection and determination of the free chlorine concentration in aqueous solutions using linear sweep voltammetry (LSV) and amperometric i–t curve techniques. The CGO–SnO2 electrodes worked through the direct electrochemical reduction of hypochlorite ions (ClO−) on the surface of the electrode, which was used to determine the free chlorine concentration. The electrodes operate over a wide linear range of 0.1–10.08 ppm, with a sensitivity of 2.69 µA µM−1 cm−2. Further, selectivity studies showed that these electrodes easily conquer the electrochemical signals of other common ions in drinking water distribution systems, and only shows the electrochemical reduction signals of free chlorine. Finally, the CGO–SnO2 electrodes were successfully employed for the detection of free chlorine in tap water solutions (St. Louis, MO 63130, USA) with a sensitivity of 5.86 µA µM−1 cm−2. Overall, the sensor fabricated using simple and scalable aerosol-based techniques showed a comparable performance to previous studies on amperometric chlorine sensing using carbon-based electrodes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The quality of drinking water has to be monitored continuously to avoid waterborne diseases including cholera, diarrhea, and typhoid fever in many developing nations. Chlorine is the most commonly used disinfectant for the treatment of various water resources including drinking water, waste water, and swimming pools. The environmental protection agency (EPA) requires water supply utilities to maintain a residual disinfectant concentration throughout the distribution system to inhibit microbial re-contamination of treated drinking water. The addition of NaOCl as a chlorine source in water generates both hypochlorite ions (ClO−) and hypochlorous acid (Qin et al. 2015).

High levels of chlorine can have negative health effects such as eye/nose irritation, stomach discomfort, anemia, and nervous system affects in some infants (Chowdhury et al. 2014). In the ecosystem, excess chlorine residuals can interact with organic matter to form disinfection by-products (DBPs). These DBPs are toxic and pose a threat to the health of consumers. The EPA has established maximum contaminant levels (MCLs) for DBPs, which apply to both large community water systems and non-transient, non-community water systems that add disinfectant. Small communities are particularly vulnerable to compliance failures with regulatory standards for DBPs, which can be largely attributed to the limited resources available for monitoring (Sinha et al. 2006; Hall et al. 2007).

Due to this, different types of analytical methods are being used to monitor free chlorine residuals. The most common methods include, spectrophotometric monitoring (Moberg and Karlberg 2000; March and Simonet 2007; He and Yu 2015), interferometry (Xu et al. 2011), colorimetry (Lou et al. 2011) and electroanalytical methods (Soldatkin et al. 1997; Campo et al. 2005; Kishioka et al. 2005; Kodera et al. 2005; Thiagarajan et al. 2011). Among these, electroanalytical methods are advantageous in their robustness, low cost, ease of use, and real-time monitoring capabilities. One of the most commonly used techniques for online free chlorine (part of chlorinated water not reacted with any contaminants) monitoring is amperometric sensing. Prussian blue electrodes (Salazar et al. 2015), gold thin film microelectrodes (Olivé-Monllau et al. 2009), and nano-Au film electrodes (Thiagarajan et al. 2011), have been applied as amperometric chlorine sensors; however, these devices have high costs due to the use of expensive noble metals as electrode materials (Hall et al. 2007).

To overcome this hurdle, simple, low-cost materials must be developed for the real-time detection and determination of free chlorine in water distribution systems. Recently, graphene-based nanomaterials have shown promise as an electrochemical, optical, and biological sensing material (Kochmann et al. 2012). More specifically, carbon-based composite materials, including carbon nanotube composite electrodes (Olivé-Monllau et al. 2011), carbon nanotube–epoxy composites (Olivé-Monllau et al. 2010), multi-walled carbon nanotube/epoxy with CuO nanoparticles (Muñoz et al. 2015), and chemically modified graphite-based electrodes, were used for free chlorine sensing (Pan et al. 2015). Further, graphene and metal oxide nanocomposites have been successfully utilized for electrochemical biosensing applications. For example, graphene/SnO2 nanocomposite-modified electrodes (Sun et al. 2013; Nurzulaikha et al. 2015), and octahedral SnO2 nanocrystals bounded by reduced graphene oxide nanosheets for the electrochemical determination of dopamine were reported (Ma et al. 2015). In addition, quantum sized SnO2-conjugated reduced graphene oxide nanocomposite were applied as non-enzymatic glucose sensors (Ye et al. 2014; Mohd Yazid et al. 2014; Fu et al. 2015). Typically, the fabrication process for these electrodes is complex, requiring multiple steps where each material is synthesized independently and combined in additional steps with limited control over the final morphology (McCreery 2008; Muñoz et al. 2015).

Herein, we focus on the development of metal oxide–graphene nanocomposite sensors using aerosol-based synthesis routes—aerosol chemical vapor deposition (ACVD) and electrospray deposition (Shah et al. 2012; Kavadiya et al. 2016, 2017)—for the electrochemical detection of free chlorine. Aerosol-based synthesis routes are advantageous due to their scalability and low cost while still maintaining precise control and flexibility in deposition (Pratsinis 2010; Jiang et al. 2016, 2017). For electrode fabrication, SnO2-nanostructured columns were produced using ACVD and functionalized with crumpled graphene oxide (CGO) using electrospray deposition (Shah et al. 2015). The main advantage of these aerosol-based techniques is the single step synthesis and deposition of the material on the substrate in the desired morphology (Zhan et al. 2010). The two-step synthesis approach of the electrode offers precise control over the material ratio and maintains the chemical composition and morphology of the individual structures. We have demonstrated the electrode performance for the detection of free chlorine using linear sweep voltammetry (LSV) and amperometric techniques in neutral pH conditions and in real water resources (tap water, St. Louis, MO 63130, USA). In both cases, the CGO–SnO2 electrodes showed a robust performance for the electrochemical detection and determination of free chlorine.

Methods

Electrode fabrication

The SnO2-nanostructured thin films were prepared on 25 × 50 mm Corning alkaline earth boro-aluminosilicate glass coated with Indium Tin Oxide (ITO, 0.7 mm thickness, Delta Technologies, Limited, Loveland, CO) using ACVD, described in detail in previous work (Thimsen et al. 2008a, b; An et al. 2009; Chadha et al. 2014). In brief, the precursor (in vapor phase) is introduced into the reactor zone and converted to metal oxide particles. As the particles travel through the reactor via convective flow, growth occurs through coagulation and coalescence. The particles are eventually deposited onto the ITO substrate by diffusion in the boundary layer, along with any unreacted precursor vapor (Kulkarni and Biswas 2004). Following deposition, particle sintering and further growth on the substrate occurs as the deposited particles interact with the unreacted precursor vapor and the subsequently deposited particles. For the growth of the SnO2 nanocolumns in the ACVD system, tetramethyl tin (TMT, Sigma-Aldrich, MO, USA) was used as the precursor. The precursor was delivered via a bubbler at a rate of 11 ccm with nitrogen (N2) as a carrier gas and oxygen was used as a dilution flow, delivered at a rate of 100 ccm. For this study, the substrate temperature was fixed at 600 °C, the distance between the feeding tube and substrate was fixed at 1 cm, and the deposition time was 30 min. All the parameters used for the growth of SnO2 nanostructure were optimized based on the framework developed in previous studies (An et al. 2010).

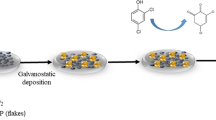

Following the deposition of nanostructured SnO2 thin films, the surface was decorated with CGO. First, graphene oxide sheets were synthesized using Hummer’s method (Hummers and Offeman 1958; Wang et al. 2012a, b). The solution was sonicated for 1 h prior to the electrospray process to ensure the exfoliation of the GO sheets was maintained. A precursor solution containing GO sheets was then prepared by adding 3 mM of ammonium acetate to a 0.31 mg ml−1 of GO solution. Using an electrospray deposition system, the GO sheets were aerosolized to yield a crumpled structure and deposited on the SnO2 thin films in a single step. Electrospray is an atomization technique to generate nanoparticles from a liquid solution at ambient conditions using an electric field (Fig. 1). The electrospray technique has been described and used previously to self-assemble molecules and deposit on metal oxide thin films (Shah et al. 2015; Kavadiya et al. 2016). Moreover, electrospray can be used to crumple GO sheets via evaporation induced crumpling. Briefly, GO precursor solution is pumped at a flow rate of 1 μL min−1 through a capillary needle. An electric field is applied in the deposition chamber by connecting the needle to a high voltage source and the substrate to the ground. The electrospray system was operated in the Taylor cone-jet mode to obtain monodisperse droplets. Through the evaporation of the solvent, the GO sheets in the droplet are converted into crumpled GO particles, which then deposit on the substrate. The spray solution properties and electrospray conditions used for these sensors are detailed in Table 1.

Material characterization

The thickness and morphology of the deposited SnO2 columns were characterized using scanning electron microscopy (SEM, FEI NovaNanoSEM 230, OR, USA), carried out at 15 kV. The crystallinity of the film was characterized using X-ray diffraction (XRD, Bruker d8 Advance, MA, USA), with Cu Kα radiation (λ = 1.5406 Å) and operated at 40 kV and 40 mA. The growth direction and crystal structure of the individual nanocolumns were confirmed using high-resolution transmission electron microscopy (HRTEM, JEOL JEM-2100F, MA, USA), carried out at 200 kV. The morphology of the CGO particle was imaged using transmission electron microscopy (TEM, FEI Transmission Electron Microscope, OR, USA). The elemental composition and purity of the thin films was analyzed using X-ray photoelectron spectroscopy (XPS, Physical Electronics 5000 Versa Probe II Scanning ESCA MN, USA).

Electrochemical testing

All the electrochemical and electroanalytical experiments were carried out using a three-electrode setup, with the synthesized composite material on ITO as the working electrode, Ag/AgCl as the reference electrode, and platinum wire as the counter electrode. A CHI 760 bipotentiostat (CH Instruments, Austin, USA) was used for all the electrochemical measurements (cyclic voltammetry (CV), linear sweep voltammetry (LSV), and amperometric i–t curve). All the electrochemical solutions were prepared using ultra-pure deionized water. The experiments were performed using a phosphate buffer solution (PBS, pH 7.4) and purged with ultra-pure nitrogen gas. The CV and LSV measurements were carried out in a voltage rage of 0.8 to −0.8 (V), scanned at a rate of 100 mV s−1. We also employed the amperometric i–t curve technique, where the potential was fixed at −0.45 V and the current response was measured as a function of time. Following the electrochemical characterization of the electrode, the selectivity of the electrode for free chlorine was tested. An amperometric i–t curve was studied to determine the interference of different species including Na+, K+, Ca2+, NO3 −, and SO4 2−. At the fixed potential range (−0.45 V), the current response was measured with the addition of interfering compounds including, KCl (1.02 mM), KNO3 (1 mM), CaSO4 (0.98 mM), NaSO4 (0.96 mM), and NaCl (0.95 mM). All of these compounds were added at concentrations similar to those found in tap and recreational water sources.(Muñoz et al. 2015) Finally, Saint Louis City tap water (MO, 63130 USA) was used to analyze the performance of the electrode under real-world conditions.

Results and discussion

Material characterization and film fabrication

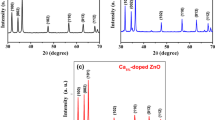

The SnO2 nanocolumns of the films deposited via ACVD had an average height of 4.8 µm and an average cross-section of 140 nm (Fig. 2c). XPS analysis was used to confirm the purity of the SnO2, and only showed a small carbon impurity peak that can be attributed to surface carbon (Fig. 2a). The XRD patterns obtained for the bare SnO2 films are consistent with that expected for cassiterite (PDF 01-071-5323), as shown in Fig. 2b. The pattern indicates preferential growth along the (211) plane, which is a high index plane that should have improved catalytic activity due to increased density of dangling bonds (Tian et al. 2007; Han et al. 2009).

Physicochemical characterization: a XPS spectra of the as-deposited SnO2 nanocolumn thin films on Si wafer, demonstrating the surface purity of the prepared sensing elements. b XRD of SnO2 nanostructured thin films grown for 30 min at 600 °C. Reference PDF#01-071-5323 (RDB). Cross-sectional SEM images of (c) SnO2 nanostructured thin films and d CGO–SnO2 composite films. e High magnification SEM images of the CGO sheets attached to the surface of SnO2 nanocolumn. Top-view SEM images of e and f TEM image of individual crumpled graphene oxide sheet. The arrow shows the tip of uncoated SnO2 nanostructure (c) and coated SnO2 nanostructure with CGO (d–e)

The graphene oxide sheets were crumpled using electrospray and then deposited onto the SnO2 nanostructured thin film, with the composite film shown in Fig. 2d. The voltage is adjusted to create a stable Taylor cone-jet at the tip of the needle, resulting in the production of monodispersed droplets. The charged droplets then travel in the electric field towards the substrate. As the droplet travels towards the substrate, the solvent evaporates causing a confinement (capillary) force that crumples the GO sheets. The solvent is completely evaporated before reaching the substrate. The crumpled nanoparticles deposit and adhere to the nanostructured SnO2 thin films via van der Waals forces. The CGO nanoparticle, shown in Fig. 2f had an average diameter of around 200 nm. The total amount of CGO deposited on the electrode was about 4.5 µg. The SnO2 base films decorated with CGO were characterized by SEM (Fig. 2c–e). The base columnar structure of the thin films remained the same before and after CGO deposition, with some breakage of the columnar structure upon CGO loading. As shown by the high magnification SEM images, the CGO coated the surface of the nanocolumns (Fig. 2e). The use of CGO increases the surface area as compared to GO sheets by preventing sheet aggregation due to pi–pi interactions. In addition, the SnO2 base layer acts as a template for the graphene material, which further increases the available surface area as compared to crumpled sheets deposited on a surface.

Electrochemical detection of free chlorine

To investigate the electroanalytical performance, the CGO–SnO2-modified electrodes were tested for the detection of free chlorine in a three-electrode electrochemical cell setup in a PBS solution (pH 7.4) using cyclic voltammetry (CV). Figure 3a shows the CV response of the bare ITO electrode in the presence of 1.20 ppm NaOCl in pH 7.4 PBS solution, which shows a null detection response. Figure 3b and c shows the electrochemical reduction peak for free chlorine at the SnO2 and CGO electrodes, respectively. The SnO2 electrode shows an electrochemical reduction peak at −0.42 V with the current increment of 44.25 µA. The strong reduction peak can be attributed to the large surface area and superior electrical properties of the nanocolumn thin films. The nanostructured columns not only result in a large surface for reaction but also minimize the charge barriers for electrons and increases electron lifetime (Thimsen et al. 2008a, b; Wang et al. 2012a, b; Chadha et al. 2014). The CGO electrode also shows a reduction peak at around −0.42 V, with the current increment of 5.7 µA. Because graphene oxide is an insulator, the moderate reduction peak is a function of the extent of surface reactions such as adsorption, which are facilitated by CGO’s large surface area and, potentially, by the functional groups on the surface. Finally, the CGO–SnO2 composite electrode (Fig. 3d) shows the best electrochemical reduction response at −0.44 V, with a current increment of 60.80 µA. This result clearly shows that the combination of SnO2 nanocolumns and CGO has a superior electrocatalytic performance compared to the individual SnO2 and CGO films for the detection of free chlorine in the pH 7.4 PBS, which can be attributed to the synergistic effects of the composite material. The CGO on the surface of the nanocolumns results in increased surface reactions, and the single crystal nanocolumns allow for efficient electron transfer for these reactions at the electrode surface.

The electrochemical reduction mechanism of NaOCl at CGO–SnO2 electrodes, which has been shown to occur at roughly −0.42 V (Kodera et al. 2005; Olivé-Monllau et al. 2010, 2011; Thiagarajan et al. 2011; Kiss et al. 2014; Senthilkumar and Zen 2014; Tang et al. 2014; Muñoz et al. 2015; Salazar et al. 2015; Wang and Anzai 2015) is as follows:

To study the effect of analyte concentration on the electrocatalytic activity of SnO2–CGO, LSV was employed for the detection of free chlorine (Fig. 4). The concentration of NaOCl in the electrolyte was increased from 0.1 to 10.08 ppm and the corresponding change in current was measured. Figure 4 shows the LSV responses of the CGO–SnO2 electrode at six different concentrations of NaOCl (0, 0.1, 0.9, 4.01, 8.05, 10.08 ppm, increasing from a to f). Here, the LSV shows a well-defined electrochemical reduction peak for the detection of free chlorine at around −0.45 V. Further the reduction peak intensity increases along with the concentration of ClO−. This result confirms that CGO–SnO2 electrode has high sensitivity within the tested concentration range (of 0.1–10.08 ppm), which encompasses the concentration of chlorine found in drinking water distribution systems. Furthermore, the calibration curve (Fig. 4, inset) was plotted from the LSV response at the reduction peak and the sensitivity of the electrode was calculated to be 2.69 µA µM−1 cm−2.

To study the effect of interfering compounds on the performance of the electrode, an amperometric i–t curve was produced (Fig. 5). While there was no change with the addition of each interfering compounds (KCl, KNO3, CaSO4, NaSO4, NaCl), a slight decrease in the current magnitude was observed overall. Following the addition of interfering compounds, upon further addition of NaOCl (0.1 mM), the proposed electrode clearly shows a large, stepwise increment in the current response for the electrochemical reduction of ClO−, even at this low concentration. This behavior confirms that the CGO–SnO2 electrode overcomes the interference effect of various ions at relatively high concentrations (1 mM). Finally, the results validate the application of the CGO–SnO2 electrodes for the selective, real-time sensing of free chlorine.

Detection of free chlorine in tap water

To validate the potential real-time sensing response, we have examined the electrocatalytic properties of CGO–SnO2 electrode to detect free chlorine in tap water. Saint Louis city tap water (MO, 63130 USA) was collected and used to directly prepare the stock solutions with NaOCl at various concentrations. The LSV technique, with a potential window of 0.8 to −0.8 V and a scan rate of 100 mV s−1, was again employed to determine the free chlorine concentration in PBS solution. Figure 6 shows the LSV response of the CGO–SnO2 electrode for various concentrations of ClO− ions. For increasing concentrations of ClO−, the corresponding reduction peak increases linearly. This confirms that the proposed electrode successfully detects free chlorine in tap water samples. The linear range of detection for free chlorine is 0.1–10.08 ppm. The inset of Fig. 6 shows the current vs. concentration plot for the detection of free chlorine in the tap water. From the calibration curve, the sensitivity of the CGO–SnO2 electrode for the detection of free chlorine was found to be 5.86 µA µM−1 cm−2. These electroanalyses studies clearly show that the CGO–SnO2 electrode effectively detects free chlorine in real water resource samples. Further, the linear range of this electrode falls within the acceptable limit to detect free chlorine (0.1–10.08 ppm) set by the various monitoring agencies. We also compared the results of CGO–SnO2 electrodes with other electrode materials reported in the literature. Table 2 shows the comparison studies of the present electrodes for the detection and determination of free chlorine. We can see that the electrode possesses a reasonable linear range of detection for free chlorine sensing (0.1–10.08 ppm) compared to other electrode materials.

Stability studies

The stability of the proposed electrode was examined before and after the detection of free chlorine. After the electroanalytical studies, the CGO–SnO2 electrode was tested in a pH 7.4 PBS solution using CV at a scan rate of 100 mV s−1 and the background response was recorded (Fig. 7, curve a). The electrode was then stored in open air under ambient conditions (25 °C) for 5 days. On the fifth day, the electrode was re-examined using the same procedures to determine the background current response in pH 7.4 PBS (Fig. 7, curve b). From Fig. 7, curve b, we observe that there is only a slight shift in the reduction scan but no large drop in the background current response. Based on this result, we can conclude that the CGO–SnO2 electrode is electrochemically sensitive, selective, and stable at standard temperature and pressure conditions and could be reused for the multiple analyses.

Conclusion

We have successfully fabricated CGO–SnO2 nanocomposite electrodes using ACVD and electrospray deposition techniques. As-prepared CGO–SnO2 electrodes were successfully employed for the detection of free chlorine in the pH 7.4 PBS and in real tap water. In both cases, the CGO–SnO2 electrodes showed excellent sensitivity for the detection of free chlorine within the acceptable linear range (ppm). In addition, these electrodes overcome the interference effects of other ions commonly found in tap water and only shows selective electrochemical response for the detection-free chlorine. These electrodes, deposited via a highly simplified deposition approach had a chlorine sensing performance comparable to those previously reported in the literature for more complex and extensively optimized processes. The electrode fabrication procedure for sensor applications is novel, cost effective, and scalable. Furthermore, this method of electrode fabrication could be optimized and expanded for other electrochemical biosensing, and environmental sensing applications.

References

An W-J, Thimsen E, Biswas P (2009) Aerosol-chemical vapor deposition method for synthesis of nanostructured metal oxide thin films with controlled morphology. J Phys Chem Lett 1:249–253

An W-J, Thimsen E, Biswas P (2010) Aerosol-chemical vapor deposition method for synthesis of nanostructured metal oxide thin films with controlled morphology. J Phys Chem Lett 1:249–253

Campo FJD, Ordeig O, Muñoz FJ (2005) Improved free chlorine amperometric sensor chip for drinking water applications. Anal Chim Acta 554:98–104

Chadha TS, Tripathi AM, Mitra S, Biswas P (2014) One-dimensional, additive-free, single-crystal TiO2 nanostructured anodes synthesized by a single-step aerosol process for high-rate lithium-ion batteries. Energy Technol 2:906–911

Chowdhury S, Alhooshani K, Karanfil T (2014) Disinfection byproducts in swimming pool: occurrences, implications and future needs. Water Res 53:68–109

Fu L, Zheng Y, Wang A, Cai W, Fu Z, Peng F (2015) A novel nonenzymatic hydrogen peroxide electrochemical sensor based on SnO2-reduced graphene oxide nanocomposite. Sens Lett 13:81–84

Hall J, Zaffiro AD, Marx RB, Kefauver PC, Krishnan ER, Haught RC, Herrmann JG (2007) On-line water quality parameters as indicators of distribution system contamination. Am Water Works Assoc 99:66–77

Han X, Jin M, Xie S, Kuang Q, Jiang Z, Jiang Y, Xie Z, Zheng L (2009) Synthesis of tin dioxide octahedral nanoparticles with exposed high-energy 221 facets and enhanced gas-sensing properties. Angew Chem 121:9344–9347

He Y, Yu H (2015) A novel triangular silver nanoprisms-based surface plasmon resonance assay for free chlorine. Analyst 140:902–906

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339

Jiang Y, Raliya R, Fortner JD, Biswas P (2016) Graphene oxides in water: correlating morphology and surface chemistry with aggregation behavior. Environ Sci Technol 50(13):6964–6973

Jiang Y, Raliya R, Liao P, Biswas P, Fortner JD (2017) Graphene oxides in water: assessing stability as a function of material and natural organic matter properties. Environ Sci Nano 4:1484–1493

Jović M, Cortés-Salazar F, Lesch A, Amstutz V, Bi H, Girault HH (2015) Electrochemical detection of free chlorine at inkjet printed silver electrodes. J Electroanal Chem 756:171–178

Kavadiya S, Chadha TS, Liu H, Shah VB, Blankenship RE, Biswas P (2016) Directed assembly of the thylakoid membrane on nanostructured TiO2 for a photo-electrochemical cell. Nanoscale 8:1868–1872

Kavadiya S, Raliya R, Schrock M, Biswas P (2017) Crumpling of graphene oxide through evaporative confinement in nanodroplets produced by electrohydrodynamic aerosolization. J Nanopart Res 19(2):43

Kishioka S-Y, Kosugi T, Yamada A (2005) Electrochemical determination of a free chlorine residual using cathodic potential-step chronocoulometry. Electroanalysis 17:724–726

Kiss L, Kovács B, Nagy G (2014) Direct chronoamperometric determination of free available chlorine in soil samples using built-in diffusion layer coated glassy carbon electrode. J Solid State Electrochem 19:261–267

Kochmann S, Hirsch T, Wolfbeis OS (2012) Graphenes in chemical sensors and biosensors. TrAC Trends Anal Chem 39:87–113

Kodera F, Umeda M, Yamada A (2005) Determination of free chlorine based on anodic voltammetry using platinum, gold, and glassy carbon electrodes. Anal Chim Acta 537:293–298

Kulkarni P, Biswas P (2004) A Brownian dynamics simulation to predict morphology of nanoparticle deposits in the presence of interparticle interactions. Aerosol Sci Technol 38:541–554

Lou X, Zhang Y, Li Q, Qin J, Li Z (2011) A highly specific rhodamine-based colorimetric probe for hypochlorites: a new sensing strategy and real application in tap water. Chem Commun 47:3189–3191

Ma HF, Chen TT, Luo Y, Kong FY, Fan DH, Fang HL, Wang W (2015) Electrochemical determination of dopamine using octahedral SnO2 nanocrystals bound to reduced graphene oxide nanosheets. Microchim Acta 182:2001–2007

March JG, Simonet BM (2007) A green method for the determination of hypochlorite in bleaching products based on its native absorbance. Talanta 73:232–236

McCreery RL (2008) Advanced carbon electrode materials for molecular electrochemistry. Chem Rev 108:2646–2687

Moberg L, Karlberg B (2000) An improved N, N′-diethyl-p-phenylenediamine (DPD) method for the determination of free chlorine based on multiple wavelength detection. Anal Chim Acta 407:127–133

Mohd Yazid SNA, Md Isa I, Abu Bakar S, Hashim N, Ab Ghani S (2014) A review of glucose biosensors based on graphene/metal oxide nanomaterials. Anal Lett 47:1821–1834

Muñoz J, Céspedes F, Baeza M (2015) Modified multiwalled carbon nanotube/epoxy amperometric nanocomposite sensors with CuO nanoparticles for electrocatalytic detection of free chlorine. Microchem J 122:189–196

Murata M, Ivandini TA, Shibata M, Nomura S, Fujishima A, Einaga Y (2008) Electrochemical detection of free chlorine at highly boron-doped diamond electrodes. J Electroanal Chem 612:29–36

Nurzulaikha R, Lim HN, Harrison I, Lim SS, Pandikumar A, Huang NM, Lim SP, Thien GSH, Yusoff N, Ibrahim I (2015) Graphene/SnO2 nanocomposite-modified electrode for electrochemical detection of dopamine. Sens Bio Sens Res 5:42–49

Olivé-Monllau R, Orozco J, Fernández-Sánchez C, Baeza M, Bartrolí J, Jimenez-Jorquera C, Céspedes F (2009) Flow injection analysis system based on amperometric thin-film transducers for free chlorine detection in swimming pool waters. Talanta 77:1739–1744

Olivé-Monllau R, Pereira A, Bartrolí J, Baeza M, Céspedes F (2010) Highly sensitive CNT composite amperometric sensors integrated in an automated flow system for the determination of free chlorine in waters. Talanta 81:1593–1598

Olivé-Monllau R, Martínez-Cisneros CS, Bartrolí J, Baeza M, Céspedes F (2011) Integration of a sensitive carbon nanotube composite electrode in a ceramic microanalyzer for the amperometric determination of free chlorine. Sens Actuators B Chem 151:416–422

Ordeig O, Mas R, Gonzalo J, Del Campo FJ, Muñoz FJ, de Haro C (2005) Continuous detection of hypochlorous acid/hypochlorite for water quality monitoring and control. Electroanalysis 17:1641–1648

Pan S, Deen MJ, Ghosh R (2015) Low-cost graphite-based free chlorine sensor. Anal Chem 87:10734–10737

Pratsinis SE (2010) Aerosol-based technologies in nanoscale manufacturing: from functional materials to devices through core chemical engineering. AIChE J 56:3028–3035

Qin Y, Kwon H-J, Howlader MMR, Deen MJ (2015) Microfabricated electrochemical pH and free chlorine sensors for water quality monitoring: recent advances and research challenges. RSC Adv 5:69086–69109

Salazar P, Martín M, García-García FJ, González-Mora JL, González-Elipe AR (2015) A novel and improved surfactant-modified Prussian Blue electrode for amperometric detection of free chlorine in water. Sens Actuators B Chem 213:116–123

Senthilkumar K, Zen J-M (2014) Free chlorine detection based on EC’ mechanism at an electroactive polymelamine-modified electrode. Electrochem Commun 46:87–90

Shah VB, Orf GS, Reisch S, Harrington LB, Prado M, Blankenship RE, Biswas P (2012) Characterization and deposition of various light-harvesting antenna complexes by electrospray atomization. Anal Bioanal Chem 404:2329–2338

Shah VB, Henson WR, Chadha TS, Lakin G, Liu H, Blankenship RE, Biswas P (2015) Linker-free deposition and adhesion of photosystem I onto nanostructured TiO2 for biohybrid photoelectrochemical cells. Langmuir 31:1675–1682

Sinha R, Krishnan E, Muhammad N, Patterson C, Haught R (2006). Evaluation of ceramic filtration for drinking water treatment in small systems. In: World environmental and water resource congress 2006, American Society of Civil Engineers, pp 1–11

Soldatkin AP, Gorchkov DV, Martelet C, Jaffrezic-Renault N (1997) New enzyme potentiometric sensor for hypochlorite species detection. Sens Actuators B Chem 43:99–104

Sun W, Wang X, Wang Y, Ju X, Xu L, Li G, Sun Z (2013) Application of graphene–SnO2 nanocomposite modified electrode for the sensitive electrochemical detection of dopamine. Electrochim Acta 87:317–322

Tang Y, Su Y, Yang N, Zhang L, Lv Y (2014) Carbon nitride quantum dots: a novel chemiluminescence system for selective detection of free chlorine in water. Anal Chem 86:4528–4535

Thiagarajan S, Wu Z-Y, Chen S-M (2011) Amperometric determination of sodium hypochlorite at poly MnTAPP-nano Au film modified electrode. J Electroanal Chem 661:322–328

Thimsen E, Rastgar N, Biswas P (2008) Nanostructured TiO2 films with controlled morphology synthesized in a single step process: performance of dye-sensitized solar cells and photo watersplitting. J Phys Chem C 112:4134–4140

Tian N, Zhou Z-Y, Sun S-G, Ding Y, Wang ZL (2007) Synthesis of tetrahexahedral platinum nanocrystals with high-index facets and high electro-oxidation activity. Science 316:732–735

Tsai TH, Lin KC, Chen SM (2011) Electrochemical synthesis of poly(3,4-ethylenedioxythiophene) and gold nanocomposite and its application for hypochlorite sensor. Int J Electrochem Sci 6:2672–2687

Wang B, Anzai JI (2015) A facile electrochemical detection of hypochlorite ion based on ferrocene compounds. Int J Electrochem Sci 10:3260–3268

Wang W-N, An W-J, Ramalingam B, Mukherjee S, Niedzwiedzki DM, Gangopadhyay S, Biswas P (2012a) Size and structure matter: enhanced CO2 photoreduction efficiency by size-resolved ultrafine Pt nanoparticles on TiO2 single crystals. J Am Chem Soc 134:11276–11281

Wang W-N, Jiang Y, Biswas P (2012b) Evaporation-induced crumpling of graphene oxide nanosheets in aerosolized droplets: confinement force relationship. J Phys Chem Lett 3:3228–3233

Xu J, Feng K, Weck M (2011) Free chlorine sensing using an interferometric sensor. Sens Actuators B Chem 156:812–819

Ye Y, Wang P, Dai E, Liu J, Tian Z, Liang C, Shao G (2014) A novel reduction approach to fabricate quantum-sized SnO2-conjugated reduced graphene oxide nanocomposites as non-enzymatic glucose sensors. Phys Chem Chem Phys 16:8801–8807

Zhan Z, Wang W-N, Zhu L, An W-J, Biswas P (2010) Flame aerosol reactor synthesis of nanostructured SnO2 thin films: high gas-sensing properties by control of morphology. Sens Actuators B Chem 150:609–615

Acknowledgements

The work was partially supported by the Lucy and Stanley Lopata Endowment at Washington University in St. Louis. Additional support was provided by the McDonnell Academy Global Energy and Environmental Partnership (MAGEEP). Author also acknowledges the chemistry seed Grant research awarded from NTU for this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Soundappan, T., Haddad, K., Kavadiya, S. et al. Crumpled graphene oxide decorated SnO2 nanocolumns for the electrochemical detection of free chlorine. Appl Nanosci 7, 645–653 (2017). https://doi.org/10.1007/s13204-017-0603-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-017-0603-x