Abstract

Carbonate reservoirs account for 60% share in global oil reserves, and CO2-EOR process is employed in these carbonate fields for effective oil recovery and retention as well. Recent research reports that fines migration may lead to reservoir formation damage in oil bearing limestone and dolomite rocks. Although carbonate reservoirs are poor in clay minerals, some mass of clay fines existence in certain carbonate formations will cause severe damage to permeability and well productivity. This paper reports the single-phase flow of subcritical CO2 in porous limestone rock core containing kaolinite clay fines. Fines are natural reservoir minerals (example, quartz) and clay particles such as kaolinite, illite, feldspar, smectite, and montmorillonite. But, this paper explores this CO2-clay fines behavior in limestone rock as a function of kaolinite. So, two sets of core flood experiments were performed in the rock temperatures 120 °C and 160 °C. Initially, kaolinite clay has been injected into the limestone core in the form of suspension and then dried for hours in order to retain the solid fines in the internal pore chambers of the core. After that, the CO2 under subcritical condition has been injected into the porous limestone core for fines mobilization and injected gas recovery. The major observations that are reported from the experimental tests are there is an increase in gas saturation for increasing injection time. Steady rise of heat transfer coefficient and enthalpy was noted for increasing gas saturation and time. Concentration of fines linearly soars with respect to elevating PVI and permeability declines for rising time. Pressure in the limestone core shows abnormal and nonlinear variation. Finally, gas discharge rate declines for increasing injection time. Experimental data are tested against the statistical model (regression), and the outcome indicated good agreement. Overall, this paper has successfully established the CO2 effects on kaolinite clay fines behavior and its impact on oil recovery in carbonate fields.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

CO2 injection in carbonate reservoir either for carbon capture and storage (CCS) or enhanced oil recovery (EOR) will lead to many complicated geochemical and surface reactions (Singh et al. 2018; Agada et al. 2016). During CO2, EOR process a certain quantity of gas will be retained in the pore spaces (Olea 2015). On the other side, fines migration in carbonate fields is posing great risk to reservoir formation damage and well productivity deterioration. CO2 injection in subsurface environment will undergo different trapping mechanism and one being mineral trapping, and even carbonate minerals trap carbon dioxide in carbonate reservoirs (Király et al. 2017). An introduction about fines is already described in abstract section and, usually, kaolinite clay fines are common in a sandstone reservoir since these reservoir rocks contain quartz and feldspar, and moreover, the pore walls of sandstone rocks are coated with kaolinite clay (Wu et al. 2012). Kaolinite occurs in sandstone rocks upon the dissolution of feldspar at extreme temperature and geochemical alterations. Typically, carbonate reservoirs are poor in clay minerals, but kaolinite comprising carbonate rocks shows higher grain density than other clay containing rocks (Aoyagi and Chilingarian 1972). Earlier, clay minerals, especially kaolinite, are discovered in certain carbonate oil reservoirs, for instance, Bombay High Oil Field in India during 1981 (Rao 1981). Generally, fines have a size of the order 1 µm and a net surface charge (Raha et al. 2007). Generally, the fine mass balance equation is mentioned as follows (Yang et al. 2016; You et al. 2016):

where \(\sigma_{s} + \sigma_{a} = {\text{Concentrations}}\;{\text{of}}\;{\text{attached}}\;{\text{and}}\;{\text{strained}}\;{\text{fines}},\)\(U = {\text{Darcy velocity}},\)\(c = {\text{Volumteric}}\;{\text{concentration}}\;{\text{of}}\;{\text{suspended}}\;{\text{particles}},\)\(t = {\text{time}},\phi = {\text{Porosity}}, \,x = {\text{Distance,}}\;{\text{and}}\;{\text{finally,}}\;\alpha = {\text{Drift}}\;{\text{delay}}\;{\text{factor}}.\)

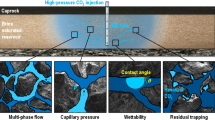

Furthermore, fines are held in porous rocks under the influences of four forces, namely lift (Fl), drag (Fd), gravity (Fg), and electrostatics (Fe), as shown in Fig. 1. The gravity and electrostatic forces hold the fines to the pore surface (Zeinijahromi et al. 2016). Also, Fig. 1 shows the fines behavior in limestone porous media during CO2 flow. To the best of our knowledge, there are no works on CO2 transport impacts on fines migration in carbonate media and thus, this may be the first paper to explore the fines behavior in porous carbonate (limestone) rocks. It has been proved that CO2 has significant impact on fines migration and permeability decline in sandstone cores (De Silva et al. 2017), but this same phenomenon should be thoroughly investigated in limestone cores.

There are certain research outlets on supercritical CO2 flow effects on fines migration in sandstones (Pearce et al. 2019; Torsæter and Cerasi 2018; Othman et al. 2018). For instance, Neuyam et al. (2017) examined the impact of fines mobilization during CO2 injection through experimentation. The authors saturated the sandstone cores with monodisperse colloid suspensions with dry supercritical carbon dioxide and performed a series of coreflooding tests. They identified that the particle concentration of 0.5 wt% in the pore fluid decreased carbon dioxide injectivity by 80%. Mainly, the authors suggested that there is a decline in porosity due to particle pore entrapment, and this is completely due to CO2 injection. Therefore, their findings clearly reported that the fines detach easily and quickly during CO2 flooding. Even, Xie et al. (2017) studied the fines migration during CO2 injection and have interpreted the experimental results with surface forces. The authors have taken reservoir core plugs from the well Harvey-1 (Australian hydrocarbon field), which contain 13% of high kaolinite content. Additionally, they used the DLVO theory and the hydrodynamic force of modeling and fines detachment calculations. Subsequently, they conducted a series of carbon dioxide core flood experiments to estimate the permeability decline. Their results revealed that during CO2 transport in porous reservoir cores, it detaches the kaolinite particles and consequently declining the permeability. The author’s outcome indicated that beyond the hydrodynamic forces, the CO2 invasion and particle geometry have a greater effect on fines detachment, straining, and permeability decrease. Hence, the overall objective of this work to conduct subcritical CO2 injection and flow in porous limestone core and analyze its impact on kaolinite clay fines migration and mobilization. Figure 2 shows the typical phase diagram of supercritical fluids, where the subcritical region is indicated.

Typical phase diagram of supercritical fluids (Kalinichev 2013)

Furthermore, the phase behavior of CO2 from the point of capture to storage is extremely important as it determines the storage capability and reactions with the reservoir rocks and fluids. For instance, Chen and Yang (2018) utilized the Peng–Robinson equation of state (PR-EOS) to study and predict the phase behavior of n-alkane–CO2–water systems with considering the mutual solubility. The phase behavior of two-phase and three-phase fluid systems with considering water solubility has been studied, and PR-EOS was adopted for accurate prediction and correlation of fluid phase. Their modeling results revealed that addition of CO2 in the two- and three-phase solutions can alter the physicochemical properties and mass proportions of binary and ternary solutions. In addition, increase in alkanes in the solution determines the critical condition of CO2 solubility in the aqueous phase. Furthermore, Zhang et al. (2019) investigated the phase behavior of CO2 storage in underground with fractured nanopores geometry. Actually, the authors examined the CO2 storage process in the fractured tight and shale reservoirs involving thermodynamic phase behavior, implications, and strategies. Firstly, the authors have modified the analytical equation of state to estimate the nanoscale phase behavior by taking pore radius and molecular interaction effects into an account. Then, they developed a novel empirical correlation for adsorption thickness in nanopores calculation. Thirdly, pressure–volume diagrams, critical properties of pure substances, and thermodynamic fluid phase equilibrium have been analyzed. The main dominating and critical parameters that govern the CO2 storage and phase behavior in these formations are bulk volume, pressure, adsorption, pore radii, and fracture geometry. Moreover, the authors proposed three optimum strategies for the determination of carbon dioxide storage in tight and shale reservoirs that are large pore radii, purified CO2 streams and low temperatures.

Additionally, CO2 phase behavior also dominates the engineering systems in the safe transport to the reservoir. Actually, the carbon dioxide gas compression ratio and purity are vital qualities in the safe fluid transport in the engineering systems, such as a pipe. For example, Dall’Acqua et al. (2017) presented a new tool to model the CO2 decompression behavior with impurities by deploying Peng–Robinson equation of state (PR-EOS). Initially, the authors studied the thermophysical properties of carbon capture and transport and found that carbon dioxide transport in pipeline contains significant amounts of impurities. These impurities in this gas may lead to ductile fracture and pipeline collapse. Therefore, during CO2 transport, it is essential to regulate this gas to undergo a decompression in order to safely transport it to reservoir for storage. Subsequently, the authors have developed a new code to model and predict the expansion wave velocity of CO2-rich mixtures based on the isentropic 1D decompression and homogenous fluid flow. They used PR-EOS to calculate the thermodynamic properties of the mixtures and its derivatives as well. In order to access its accuracy and robustness, their code has been tested initially with the hydrocarbon mixtures. Overall, their simulated expansion curves indicated good agreement with experimental data and the literature, and furthermore, saturation pressure is a major influencing parameter in the control of fracture propagation in CO2 pipelines, because the gas pressure level and stabilization determine the ductile fracture intensity in the pipeline.

The structure of the paper is described here. The second section describes the materials and methods that were used this paper, and third section critically explores the results that were obtained from experimental test, and the fourth section concludes the paper.

Materials and methods

This section presents the Materials and methods that were used in this research work. As mentioned earlier, this is a laboratory-based analysis and for that, we have acquired a limestone core of length 20 cm and in 5 cm diameter. The core is having a porosity of 28% and 200 mD. Figure 3 shows a schematic diagram of the experimental setup. It can be seen from the figure that the limestone core is placed in a stainless steel cylindrical core holder and in turn placed inside the oven. The oven is attached with a thermocouple and three pressure gauges (for measuring the pressure difference across the core). One pressure gauge is connected to the inlet and outlet flow lines of the core center and another two are connected to the inlet and outlet flow lines of the core. One side of the core holder has provisions for pneumatic piston pump (for pressure exertion) and CO2 flow, and the other side has the flow line for effluent collection. The effluent tank is partially filled with cold water in order to condense the incoming gas and particulate (suspended fine particles). The CO2 cylinder is connected to the flow lines of the core oven system, which is provided with valves, and the whole core oven thermal system is connected to the data acquisition system and subsequently, connected to the computer.

Before the start of experiment, kaolinite clay fines are injected into the limestone core. Actually, kaolinite clay fines under the mesh size 200 were immersed in water. The colloid is poured into the sprayer. The spray bottle is applied on the one side face of the limestone core for about 15 min and suspension has penetrated deep into this porous media. Then, the core is heavily loaded with kaolinite suspension. After that, the core is kept dry in oven at 40 °C for 48 h for retaining the kaolinite fines in the solid state. In this due course, the water has evaporated and moisture is completely vanished. Only leftover is kaolinite fines in the internal spaces of the pores. Kaolinite clay can exhibit a property like refractory material as it can withstand extreme temperatures. Later, the core is kept dry at room temperature for about 24 h, and during this time, the fines will settle on the pore walls. Two sets of experiments were performed at 120 °C and 150 °C. Initially, the oven was set to these temperatures. Then, the CO2 gas flow line valves is opened and mass of 20 kg is injected to the oven in order to saturate with the limestone core. Next, the pressurized air is injected into the core for fines and gas mobilization at these temperature regimes. This pneumatic piston is serving as an external pressure source. Even during CO2 transport in carbonate media it undergoes dissolution and surface reactions such as ion exchange, adsorption, wettability and geochemical alterations, etc. (Xie et al. 2018). The CO2 gas detaches the fines in porous media and makes to suspend in fluid and afterward migrates in the porous interspaces. Some amount of fines might be plugged and strained in pore throats and others might undergo processes of bridging between rock grains. The discharged CO2 is disposed in effluent tank, where the gas is condensed. This procedure is repeated for another temperature and subsequently, a series of curves were obtained, such as gas saturation, heat transfer coefficient, enthalpy release, fines concentration, permeability decline, pressure change, and gas discharge rate. The experimental test recordings are explored and discussed in the next section.

Results and discussions

This section explores the results, which were obtained through experimental tests. Figure 4 shows the variation of increasing gas saturation with respect to increasing injection time. Actually, this saturation test was conducted without the presence of fines. This was executed in order to examine the level of CO2 saturation in the porous limestone core.

Figure 4 shows that gas saturation elevates for increasing injection time. Both temperatures exhibited an increase in the gas saturation level in the carbonate rock core. Usually, higher saturation was recorded at 160 °C, and furthermore implied that higher rock core temperature can enhance the saturation of the fluid, especially gas in limestone reservoirs. 120 °C indicated close gas saturation value, and this linear increase in the gas saturation is attributed to surface energy, pore volume, pore chamber radius, and CO2 diffusion (Li et al. 2018; Kanimozhi et al. 2018; Dullien 1992). In addition, high volume of gas saturation and storage is also due to the structural trapping capability of rocks (Serno et al. 2017). Figure 5 shows the heat transfer coefficient and enthalpy variations with respect to gas saturation and time. Fig. 5a shows that the increasing gas saturation enhances the heat transfer coefficient of the limestone rock core. Already, it was indicated that rising temperature accelerates the volume of gas saturation and transfer as well. This is absolutely required for the mass transfer that is fluid and particle displacements. CO2 flow in porous media generates a high degree of supercritical heat transfer (Zhalan et al. 2014), but extreme temperatures in limestone rock leads to calcination and thermal decomposition (Valverde 2015). The condition for maximum heat transfer rate in porous media due to carbon dioxide gas flow can be written as follows:

where \(\tau_{gc} = {\text{heat}}\;{\text{distribution}}\;{\text{due}}\;{\text{to}}\;{\text{CO}}_{2} {\text{flow}}\;{\text{with}}\;{\text{respect}}\;{\text{time}},\)\(S_{g} = {\text{Gas}}\;{\text{saturation}},\)\(\alpha = {\text{Thermal}}\;{\text{diffusivity,}}\;{\text{and}}\)\(\psi\) = Depth of the reservoir (location from the surface) where the temperature dominates the fine particle detachment.

A similar observation was noted in Fig. 5b; over here, the enthalpy release rate is higher for an increasing injection time. CO2 flow in porous media produces thermal energy and heat flux (Baragh et al. 2019; Hamidi et al. 2019). Additionally, the carbon dioxide mass flow rate enhances the enthalpy of the porous media (Basirat et al. 2015). Moreover, the heat transfer coefficient and enthalpy are the governing factors in the detachment and migration of in situ fines. Fines migration also contributes to the increase in reservoir rock temperature (Pranesh and Ravikumar 2019).

Figure 6a shows the concentration of kaolinite fines variation with respect to increasing pore volume injection (PVI). It can be seen from this figure that at 1 PVI, the fines concentration was 147.7 ppm and 12.8 ppm for the temperature 120 °C and 160 °C. At 2 PVI, the kaolinite fines concentration elevated to 14 ppm and 16 ppm for these temperature levels and finally, reaching to 34.2 ppm and 37.9 ppm at 10 PVI. 160 °C rock temperature contributed in the highest concentration of kaolinite fines with increasing PVI. Actually, kaolinite fines display good thermal conductivity (Li et al. 2015) and consequently, will result in the mass deposits on the pore surface of the limestone rock core. Figure 6b presents the rate of permeability decrease with respect to increasing injection time. This decrease is absolutely due to fines lifting, suspension and straining, temperature, dissolution, and mineral precipitation. It can be seen from this figure that at 900 s, the permeability was found to be 15.7 md and 12.3 mD. These permeability values were recorded for the temperatures 120 °C and 160 °C. Then, at 1800 s, the rock core permeability was measured to be 9.6 md and 8.6 md for these same temperature levels. 1800 s of injection time contributed to 6.1% and 3.7% in permeability decline during the temperatures 120 °C and 160 °C. Finally, at 2700 s, the rock core permeability drops to 8.2 md and 7.5 md. 160 °C temperature contributes in the heavy damage to the fluid flow since the permeability during this temperature is higher than the one in 120 °C. Therefore, CO2 flow in carbonate media can alter the fluid flow characteristics of the reservoir rock regardless of fines existence. During transport in porous rocks, some amount of CO2 gas is retained in the pore chambers and this may also affect the rock permeability and porosity (Xiao et al. 2017; Pranesh 2018). Table 1 presents suspended gas discharge data in the effluent tank.

Figure 7 shows the pressure variation for increasing pore volume injection (PVI). It can be observed from the figure that for both core temperature regimes such as in 120 °C and 160 °C, the pressure rises steadily from 1 PVI to 5 PVI. Then, the pressure is stabilized between 5 and 7 PVI or to be specific, the pressure plateaued in these conditions. After that, the pressure starts to plummet sharply for enhancing pore volume injection. Typically, pressure stabilizes during the fines detachment and migration stage (Nguyen et al. 2013). Fall in pressure is attributed to fines straining and permeability blockage. Typically, the pressure across the core varies sharply, especially begins to drop during coreflood experiments (Vaz et al. 2017). Additionally, recent research reports that rock core heterogeneity affects the CO2 saturation, which consequently reduces the permeability and pressure across the core during multiphase flow (Oh et al. 2019).

Figure 8 shows the gas discharge rate with respect to increasing gas injection time. It can be seen from this figure that rate of gas discharge from the limestone core is declining rapidly for both rock temperatures. As the gas injection time increases, the discharge rate also decreases rapidly. This decline is attributed to suspension flow, where the fines will be plugged and strained in the pore-throat and also, due to the formation of fines based pore bridging, which ultimately, lead to permeability damage. Moreover, the CO2 transport in porous limestone rock core generates high temperature and typically, natural reservoir fines are easily detached at high temperatures and consequently, will lead to the permeability decline and well productivity loss as well (You et al. 2016; Schembre and Kovscek 2005). Additionally, the plugged and bridged fines decline the fluid flow pressure and as a result, there will be a loss in the fluid momentum, where there will be a loss in the mass transfer coefficient (Rezk and Foroozesh 2018). Furthermore, CO2 flow in carbonate reservoirs leads to mineral dissolution and precipitation, which overall reduces the permeability and fluid flow, and this is regardless of in situ fines migration (Khather et al. 2019). Therefore, Fig. 8 shows that 160 °C rock temperature reported heavy loss, and in this scenario, it is noted that there will be a huge decline in the injected gas recovery at high reservoir temperatures.

Figure 9 presents the model validation between experimental and statistical models. SPSS (Statistical Package for Social Science), a multiple linear regression model, was used for the analysis and validation. Both models were tested at each rock temperatures, such as in 120 °C and 160 °C. The curves are plotted between gas discharge rate (%) against CO2 injection time (s). Both models indicated a near correlation and good agreement. There are no major differences in the values. Hence, this model is reliable for laboratory-based experimental simulation of CO2 flow in porous carbonate rocks with the existence of kaolinite clay fines. Therefore, this paper has shown the importance of kaolinite clay risk in carbonate reservoirs, especially limestone rock and its impact on gas recovery during carbon dioxide flooding.

Conclusions

Primarily, subcritical CO2 flow in limestone rock enhances the gas saturation and surface energy and subsequently, detaching in situ porous kaolinite fines. We hereby made the following conclusions based on the experimental simulation tests:

Tremendous release of entropy was observed in the limestone rock. Furthermore, CO2 injection mass and time have soared the enthalpy release rate. Additionally, increasing gas saturation enhances the heat transfer coefficient of porous limestone rock. At 160 °C, the heat transfer coefficient and enthalpy release rate intensities were high.

The pressure rises steadily for increasing PVI and stabilizes between 5 PVI and 7 PVI. After that, the pressure plummets. This behavior was observed for both temperatures such as in 120 °C and 160 °C, and this phenomenon might be due to temperature, fines exerted stress, fines bridging and plugging, permeability decline, gas saturation, and rising surface energy. In addition, there is an observation of a linear increase in kaolinite fines concentration for increasing PVI. Moreover, the permeability declines for elevating CO2 injection time.

The gas discharge rate deteriorated linearly with regards to enhancing CO2 injection time. 160 °C temperature condition showed higher decline of gas recovery. Besides, there is also a slight note of slow fluid flow in the porous limestone rock, and this sluggish fluid behavior is due to detached and strained kaolinite fines. Also, experimental model is tested against the regression (statistical) models for validation. Both models testes at each rock temperature. On the whole, the models indicated good agreement. Therefore, this work has demonstrated the effects of subcritical CO2 flow in porous limestone rock containing kaolinite clay fines and its influence on oil recovery. Overall, this paper has elucidated the significance of CO2-based formation damage in carbonate gas reservoirs.

References

Agada S, Geiger S, Doster F (2016) Wettability, hysteresis and fracture-matrix interaction during CO2 EOR and storage in fractured carbonate reservoirs. Int J Greenh Gas Control 46:57–75

Aoyagi K, Chilingarian GV (1972) Clay minerals in carbonate reservoir rocks and their significance in porosity studies. Sed Geol 8:241–249

Baragh S, Shokouhmand H, Ajarostaghi SSM (2019) Experiments on mist flow and heat transfer in a tube fitted with porous media. Int J Therm Sci 137:388–398

Basirat F, Sharma P, Fagerlund F, Niemi A (2015) Experimental and modelling investigation of CO2 flow and transport in a coupled domain of porous media and free flow. Int J Greenh Gas Control 42:461–470

Chen Z, Yang D (2018) Prediction of phase behaviour for n-alkane-CO2-water systems with consideration of mutual solubility using Peng-Robinson equation of state. J Supercrit Fluids 138:174–186

Dall’Acqua D, Terenzi A, Leporini M, D’Alessandro V, Giacchetta G, Marchetti B (2017) A new tool for modelling the decompression behavior of CO2 with impurities using the Peng-Robinson equation of state. Appl Energy 206:1432–1445

De Silva GPD, Ranjith PG, Perera MSA, Dai ZX, Yang SQ (2017) An experimental evaluation of unique CO2 flow behaviour in loosely held fine particles rich sandstone under deep reservoir conditions and influencing factors. Energy 119:121–137

Dullien F (1992) Porous media: fluid transport and pore structure, 2nd edn. Academic Press, San Diego, pp 35–75

Hamidi S, Heinze T, Galvan B, Miller S (2019) Critical review of the local thermal equilibrium assumption in heterogeneous porous media: dependence on permeability and porosity contrasts. Appl Therm Eng 147:962–971

Kalinichev A (2013) A.G. Kalinichev: Supercritical Fluids. [online] Web.imt-atlantique.fr. http://web.imt-atlantique.fr/x-subatech/kalinich/en/scf.html

Kanimozhi B, Prakash J, Pranesh V, Thamizhmani V, Vishnu RC (2018) Fines surface detachment and pore-throat entrapment due to colloidal flow of lean and rich gas condensates. J Nat Gas Sci Eng 56:42–50

Khather M, Saeedi A, Myers MB, Verrall M (2019) An experimental study for carbonate reservoirs on the impact of CO2-EOR on petrophysics and oil recovery. Fuel 235:1019–1038

Király C, Szabó Z, Szamosfalvi A, Kónya P, Szabó C, Falus G (2017) How much CO2 is trapped in carbonate minerals of a natural CO2 occurrence? Energy Procedia 125:527–534

Li C, Fu L, Ouyang J, Tang A, Yang H (2015) Kaolinite stabilized paraffin composite phase change materials for thermal energy storage. Appl Clay Sci 115:212–220

Li S, Qiao C, Li Z, Hui Y (2018) The effect of permeability on supercritical CO2 diffusion coefficient and determination of diffusive tortuosity of porous media under reservoir conditions. J CO2 Utilization 28:1–14

Neuyam YAS, Ginting PUR, Timilsina B, Ursin JR (2017) The impact of fines mobilization on CO2 injectivity: an experimental study. Int J Greenh Gas Control 65:195–202

Nguyen TKP, Zeinijahromi A, Bedrikovetsky P (2013) Fines-migration-assisted improved gas recovery during gas field depletion. J Petrol Sci Eng 109:26–37

Oh J, Kim KY, Han WS, Kim M, Park E (2019) Heterogeneity effects on pressure and CO2 saturation during core-scale multiphase flow tests. J Pet Sci Eng 172:1174–1185

Olea RA (2015) CO2 retention values in enhanced oil recovery. J Pet Sci Eng 129:23–28

Othman F, Yu M, Kamali F, Hussain F (2018) Fine migration during supercritical CO2 injection in sandstone. J Nat Gas Sci Eng 56:344–357

Pearce JK, Dawnson GKW, Golab A, Knuefing L, Sommacal S, Rudolph V, Golding SD (2019) A combined geochemical and µCT study on the CO2 reactivity of Surat basin reservoir and cap-rock cores: porosity changes, minerals dissolution and fines migration. Int J Greenh Gas Control 80:10–24

Pranesh V (2018) Subsurface CO2 storage estimation in Bakken tight oil and Eagle Ford shale gas condensate reservoirs by retention mechanism. Fuel 215:580–591

Pranesh V, Ravikumar S (2019) Heat conduction and liberation of porous rock formation associated with fines migration in oil reservoir during waterflooding. J Pet Sci Eng 175:508–518

Raha S, Khilar CK, Kapur PC, Pradip P (2007) Regularities in pressure filtration of fine and colloidal suspension. Int J Miner Process 84:348–360

Rao CG (1981) Carbonate/clay-mineral relationships and the origin of protodolomite in L-2 and L-3 carbonate reservoir rocks of the Bombay high field, India. Sed Geol 29:223–232

Rezk MG, Foroozesh J (2018) Determination of mass transfer parameters and swelling factor of CO2 – oil systems at high pressures. Int J Heat Mass Transf 126:380–390

Schembre JM, Kovscek AR (2005) Mechanism of formation damage at elevated temperature. J Energy Res Technol 127:171–180

Serno S, Flude S, Johnson G, Mayer B, Karolytė R, Haszeldine RS, Gilfillan SMV (2017) Oxygen isotopes as a tool to quantify reservoir-scale CO2 pore-space saturation. Int J Greenh Gas Control 63:370–385

Singh K, Anabaraonye BU, Blunt MJ, Crawshaw J (2018) Partial dissolution of carbonate rock grains during reactive CO2 –saturated brine injection under reservoir conditions. Adv Water Resour 2018:27–36

Torsæter M, Cerasi P (2018) Geological and geomechanical factors impacting loss of near-well permeability during CO2 injection. Int J Greenh Gas Control 76:193–199

Valverde JM (2015) On the negative activation energy for limestone calcination at high temperatures nearby equilibrium. Chem Eng Sci 132:169–177

Vaz A, Bedrikovetsky P, Fernandes PD, Badalyan A, Carageorges T (2017) Determining model parameters for non-linear deep-bed filtration using laboratory pressure measurements. J Pet Sci Eng 151:421–433

Wu LM, Zhou CH, Keeling J, Tong DS, Yu WH (2012) Towards an understanding of the role of clay minerals in crude oil formation, migration, and accumulation. Earth Sci Rev 115:373–386

Xiao P, Yang Z, Wang X, Xiao H, Wang Z (2017) Experimental investigation on CO2 injection in the Daqing extra/ultra-low permeability reservoir. J Pet Sci Eng 20:765–771

Xie Q, Saeedi A, Piane CD, Esteban L, Brady PV (2017) Fines migration during CO2 injection: experimental results interpreted using surface forces. Int J Greenh Gas Control 65:32–39

Xie Q, Chen Y, Sari A, Pu W, Saeedi A, Liao X (2018) A pH-resolved wettability alteration: implications for CO2-assisted EOR in carbonate reservoirs. Energy Fuels 31:13593–13599

Yang Y, Siqueira FD, Vaz ASL, Zhenjiang Y, Bedrikovetsky P (2016) Slow migration of detached fine particles over rock surface in porous media. J Nat Gas Sci Eng 34:1159–1173

You Z, Yang Y, Badalyan A, Bedrikovetsky P, Hand M (2016) Mathematical modelling of fines migration in geothermal reservoirs. Geothermics 59:123–133

Zeinijahromi A, Farajzadeh R, Bruining JH, Bedrikovetsky P (2016) Effect of fines migration on oil-water relative permeability during two phase flow in porous media. Fuel 176:222–236

Zhalan H, Groeneveld DC, Tavoularis S (2014) Fluid-to-fluid scaling for convective heat transfer in tubes at supercritical and high subcritical pressures. Int J Heat Mass Transf 73:274–283

Zhang K, Jia N, Liu L (2019) CO2 storage in fractured nanopores underground: phase behaviour study. Appl Energy 238:911–928

Acknowledgements

VP would like to thank Dr. S. Ravikumar, Professor of Thermofluids and Material Science at JMEC, Sriperumbudur, Tamil Nadu, India, for fruitful discussions on kaolinite fines migration in carbonate rocks. Also, the authors thank the anonymous reviewer for priceless comments to improve the quality of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mahalingam, S., Pranesh, V., Kanimozhi, B. et al. Subcritical CO2 effects on kaolinite fines transport in porous limestone media. J Petrol Explor Prod Technol 10, 883–891 (2020). https://doi.org/10.1007/s13202-019-0739-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-019-0739-1