Abstract

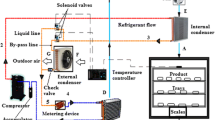

Substantial amounts of fresh agricultural food products are lost after harvest, during handling, storage, processing, and transport. Drying is a method by which food is kept from spoilage after harvest. In the current study, a simple mathematical modelling is developed for eggplant drying to reduce the physical experimentation. The governing differential equation is converted into an algebraic equation using the finite difference implicit technique. A finite difference equation is developed for each node to determine the water content, and all of the nodal equations are solved simultaneously. Eggplant slices are dried with the aid of a heat pump dryer (HPD) in a closed-loop mode in the current study. The influence of drying air temperatures (30–60 °C), relative humidities (< 20%) and air velocities (3.5, 2.5 and 1.5 m/s) in drying (equilibrium moisture content < 10%) eggplants slices is investigated. The drying rate and drying time are significantly influenced by the air velocity. Increased drying rate with reduced drying time is observed for low drying velocity of 1.5 m/s. The drying rate curves are plotted for different drying velocities and discussed. Drying rate curves indicate that the drying process materializes mostly in the first and second falling rate periods. The results of the experimentation are in accordance with the results of many earlier research studies with the similar products listed in the references. The model is validated with experimental findings. The simulated results are consistent with the experimental data. A reasonable correlation coefficient (R-square) of 0.98 is obtained for moisture concentration of eggplant slices at different interval when comparing experimental and data derived from a numerical solution of similar agricultural production crop. The moisture concentration calculated using the numerical method assuming the convective mass transfer boundary condition matches the moisture content calculated using the analytical solution assuming the moisture content at the boundary is constant at all times. The new numerical modeling developed in this study can be used to simulate the experimental data that can be obtained from a HPD for drying different kinds of eggplant slices without conducting physical experimentation.

Similar content being viewed by others

References

Akpinar EK, Bicer Y (2005) Modelling of the drying of eggplants in thin-layers. Int J Food Sci Technol 40(3):273–281

Arqub OA (2016) The reproducing kernel algorithm for handling differential algebraic systems of ordinary differential equations. Math Methods Appl Sci 39(15):4549–4562

Arqub OA, Tayebi S, Baleanu D, Osman MS, Mahmoud W, Alsulami H (2022) A numerical combined algorithm in cubic B-spline method and finite difference technique for the time-fractional nonlinear diffusion wave equation with reaction and damping terms. Results Phys 41:105912

Azadbakht M, Torshizi MV, Ziaratban A, Aghili H (2017) Energy and exergy analyses during eggplant drying in a fluidized bed dryer. Agric Eng Int: CIGR J 19(3):177–182

Azimi A, Tavakoli T, Beheshti HK, Rahimi A (2012) Experimental study on eggplant drying by an indirect solar dryer and open sun drying. Iran J Energy Environ 3(4):347–353

Babu AK, Kumaresan G, Raja VAA, Velraj R (2018) Review of leaf drying: mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew Sustain Energy Rev 90:536–556

Babu AK, Palanichamy R, Surya SBV (2022) Numerical and experimental analysis of a heat pump dryer for leaf drying applications. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02790-w

Cevikel AC, Bekir A, Arqub OA, Abukhaled M (2022) Solitary wave solutions of Fitzhugh–Nagumo-type equations with conformable derivatives. Front Phys 10:1028668

Chakraverty A, Singh RP (2014) Food preservation and processing of fruits and vegetables. Postharvest technology and food process engineering, 1st edn. CRC Press, Boca Raton

Chayjan RA, Kaveh M (2016) Drying characteristics of eggplant (Solanum melongena L.) slices under microwave-convective drying. Res Agric Eng 62(4):170–178

Colak N, Hepbasli A (2009) A review of heat pump drying: Part 1 - systems, models and studies. Energy Convers Manage 50(9):2180–2186

Culpepper CW, Moon HH (1934) Composition of eggplant fruit at different stages of matutiry in relation to its preparation and use as food. J Agric Res 47(9):705–717

Doymaz I (2008) Convective drying kinetics of strawberry. Chem Eng Process 47(5):914–919

Doymaz I (2011) Drying of eggplant slices in thin layers at different air temperatures. J Food Process Preserv 35(2):280–289

Doymaz I, Göl E (2011) Convective drying characteristics of eggplant slices. J Food Process Eng 34(4):1234–1252

Doymaz I, Tunçkal C, Göksel Z (2023) Comparison of drying kinetics, energy efficiency and color of dried eggplant slices with two different configurations of a heat pump dryer. Energy Sour Part a: Recov Util Environ Eff 45(1):690–707

ElKhodiry MA, Suwaidi SR, Taheri M, Elwalid H, ElBaba D, Qasim M (2015) Drying kinetics of eggplant (Solanum melongena) in a Fluidized bed dryer: experimental evaluation and modelling. J Food Process 2015:343945

Elsisi SF, Taha AT, Eissa AHA (2019) Quality properties changes of eggplant during microwave-oven drying. MISR J Agric Eng 36(3):879–896

Ertekin C, Yaldiz O (2004) Drying of eggplant and selection of a suitable thin layer drying model. J Food Eng 63(3):349–359

Guine RP, Correia PM, Correia AC, Goncalves F, Brito MF, Ribeiro JR (2018) Effect of drying temperature on the physical-chemical and sensorial properties of eggplant (Solanum melongena L.). Current Nutr Food Sci 14(1):28–39

Ju HY, El-Mashad HM, Fang XM, Pan Z, Xiao HW, Liu YH, Gao ZJ (2016) Drying characteristics and modeling of yam slices under different relative humidity conditions. Drying Technol 34(3):296–306

Kaya A, Aydın O, Demirtaş C (2007) Drying kinetics of red delicious apple. Biosys Eng 96(4):517–524

Kemp IC (2012) Fundamentals of energy analysis of dryers. Mod Dry Technol 4:1–45

Khan MJ, Yeasmin F, Islam MN, Ahmmed R, Das PC, Ali MH (2019) Effect of pretreatments on drying behavior of eggplant: effect of pretreatments on drying of eggplant. J Bangladesh Agric Univ 17(1):105–109

Krokida MK, Karathanos VT, Maroulis ZB, Marinos-Kouris D (2003) Drying kinetics of some vegetables. J Food Eng 59(4):391–403

Kumar N, Sarkar BC, Sharma HK (2011) Effect of air velocity on kinetics of thin layer carrot pomace drying. Food Sci Technol Int 17(5):459–469

Ozgen F (2015) Experimental investigation of drying characteristics of cornelian cherry fruits (Cornus mas L.). Heat Mass Transf 51(3):343–352

Rawya A-D, Arqub OA, Al-Smadi M, Momani S (2022) Lie symmetry analysis, explicit solutions, and conservation laws of the time-fractional Fisher equation in two-dimensional space. J Ocean Eng Sci 7(4):345–352

Russo P, Adiletta G, Di Matteo M (2013) The influence of drying air temperature on the physical properties of dried and rehydrated eggplant. Food Bioprod Process 91(3):249–256

Singh S, Singh B, Alam T (2019) Evaluation of shelf-life, antioxidant activity and nutritional quality attributes in carnauba wax coated eggplant genotypes. J Food Sci Technol 56:4826–4833

Tao Z, Yang Z, Yu F, Yang Z (2018) Effect of ultrasound on heat pump drying characteristics of pea seeds. Int J Food Eng 14(11–12):20180204

Urun GB, Yaman ÜR, Kose E (2015) Determination of drying characteristics and quality properties of Eggplant in different drying conditions. Ital J Food Sci 27(4):459–467

Wu L, Orikasa T, Ogawa Y, Tagawa A (2007) Vacuum drying characteristics of eggplants. J Food Eng 83(3):422–429

Yang Z, Yang Z, Yu F, Tao Z (2020) Ultrasound-assisted heat pump intermittent drying of adzuki bean seeds: Drying characteristics and parameter optimization. J Food Process Eng 43(10):e13501

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Human and animal rights

This is not applicable.

Informed consent

This is not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Babu, A.K., Kumaresan, G., Surya, S.B.V. et al. Drying characteristics of eggplant drying in a heat pump dryer. Int J Syst Assur Eng Manag (2024). https://doi.org/10.1007/s13198-024-02285-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13198-024-02285-z