Abstract

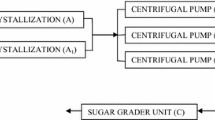

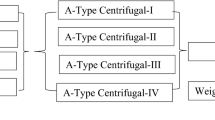

In this paper, the B-Pan crystallization system in the sugar industry is analyzed that having three subsystems—crystallizer, centrifugal machine and melter. These subsystems are arranged in series. Subsystem ‘centrifugal machine’ has standby unit, subsystem 'crystallizer' has four parallel units and subsystem ‘melter’ has single unit. The time to failure of the subsystems follows negative exponential distribution while repair time distribution is taken as arbitrary. The differential–difference equations of the system model are developed by using supplementary variable technique and solved to get state transition probabilities of B-Pan crystallization system. A particular case is also considered to show the behavior of availability and expected profit of the B-Pan crystallization system in the sugar industry.

Similar content being viewed by others

References

Aggarwal K, Singh V, Kumar S (2014) Availability analysis and performance optimization of a butter oil production system: a case study. Int J Syst Assur Eng Manag 8(1):538–554

Arora N, Kumar D (1997) Availability analysis of steam and power generation systems in the thermal power plant. Microelectron Reliab 37(5):795–799

Balagurusamy E (2009) Reliability engineering. Tata Mcgraw Hill

Cox DR (1955) Analysis of Non Markovian stochastic processes by the inclusion of supplementary variable. Proc Comb Philos Soc 51:433–441

Famurewa SM, Asplund M, Galar D, Kumar U (2013) Implementation of performance based maintenance contracting in railway industries. Int J Syst Assur Eng Mang 4(3):231–240

Garg S, Singh J, Singh DV (2010) Availability and maintenance scheduling of a repairable block-board manufacturing system. Int J Reliab Saf 4(1):104–118

Gaver DP (1963) Time to failure and availability of parallel system with repair. IEEE Trans Reliab R-12(2):30–38

Gupta P, Lal AK, Sharma RK, Singh J (2007) Analysis of reliability and availability of serial processes of plastic-pipe manufacturing plant. Int J Qual Reliab Manag 27(4):404–419

Gupta P, Lal AK, Sharma RK, Singh J (2014) Numerical analysis of reliability and availability of the serial processes in butter-oil processing plant. Int J Qual Reliab Manag 2(3):303–316

Gurjar JS (2007) Reliability technology. I.K. International, New Delhi

Jaise J, Kumar ANB, Shanmugam NS et al (2013) Power system: a reliability assessment using FTA. Int J Syst Assur Eng Manag 4(1):78–85

Kadyan MS, Kumar R (2015) Availability and profit analysis of a feeding system in sugar industry. Int J Syst Assur Eng Manag 8(1):301–316

Kaur M, Lal AK, Bhatia SS, Reddy AS (2013) On the use of corrective maintenance data for performance analysis of preventively maintained textile industry. J Reliab Stat Stud 6(2):151–163

Kumar D, Singh IP, Singh J (1988) Reliability analysis of the feeding system in the paper industry. Microelectron Reliab 28(2):213–215

Kumar D, Singh J, Pandey PC (1989a) Availability of a washing system in the paper industry. Microelectron Reliab 29(5):775–778

Kumar D, Singh J, Pandey PC (1989b) Maintenance planning for pulping system in paper industry. Reliab Eng Saf 25:293–302

Kumar D, Pandey PC, Singh J (1990) Design and cost analysis of a refining system in the sugar industry. Microelectron Reliab 30(6):1025–1028

Kumar D, Singh J, Pandey PC (1992) Availability of the crystallization system in the sugar industry under common cause failure. IEEE Trans Reliab 40(1):85–91

Kumar S, Kumar D, Mehta NP (1996) Behavioural analysis of a shell gasification and carbon recovery process in a urea fertilizer plant. Microelectron Reliab 36(4):477–480

Kumar S, Mehta NP, Kumar D (1997) Steady state behavior and maintenance planning of a desulphurization system in urea fertilizer plant. Microelectron Reliab 37(6):949–953

Lal AK, Kaur M, Leta S (2013) Behavioral study of piston manufacturing plant through stochastic models. J Ind Eng Int 9(9):1–10

Modgil V (2012) Simulation, modeling and availability analysis of sole lasting unit in shoe making industry. Int J Ind Eng Theory Appl Pract 19(2):80–89

Murari K, Goyal V (1984) Comparison of two unit cold standby reliability models with three types of repair facilities. Microelectron Reliab 24(1):35–49

Shakuntla S, Lal AK, Bhatia SS, Singh J (2011) Reliability analysis of polytube industry using supplementary variable technique. Appl Math Comput 218(8):3981–3992

Singh SB, Ram M, Chaube S (2011) Analysis of the reliability of a three-component system with two repairmen. Int J Eng Trans 24(4):395–402

Sinha RS, Mukhopadhyay AK (2015) Reliability centered maintenance of cone crusher: a case study. Int J Syst Assur Eng Manag 6(1):32–35

Suleiman K, Ali UA, Yusuf I (2013) Stochastic analysis and performance evolution of a complex thermal power plant. Innov Syst Des Eng 5(4):21–32

Zhang X, Pham H, Johnson CR (2010) Reliability models for systems with internal and external redundancy. Int J Syst Assur Eng Manag 1(4):362–369

Acknowledgements

This research paper is a part of research project F.N. 42-35/2013 (SR) under major research project scheme of University Grant Commission, Ministry Resource Development Government of India.

Author information

Authors and Affiliations

Corresponding author

Appendex 1

Appendex 1

Supplementary variable technique

When the repair rate or failure rate or both are time-dependent, the system loses its Markovian character, in this situation; the future event will not depend on present only (like Markov events) but will depend past also. These events are known as non-Markovian events.

As this paper discusses B-Pan crystallization system of the sugar industry consisting system consists of three subsystems namely crystallizer, centrifugal machine and melter with constant failure rates and arbitrary repair rates so that now the system is of non-Markovian nature. By introducing a new variable, called supplementary variable, the non-Markovian nature of the system is changed to Markovian.

Here we introduced variable x (as a supplementary variable) now the nature of the system becomes Markovian, e.g. the equation number 1(having x as a supplementary variable):

Dividing both sides by ∆t

As \(\Delta t \to 0\)

In this way, with the help of supplementary variable technique we can obtain various differential difference Eqs. (1–18).

Rights and permissions

About this article

Cite this article

Kadyan, M.S., Kumar, R. Availability based operational behavior of B-Pan crystallization system in the sugar industry. Int J Syst Assur Eng Manag 8 (Suppl 2), 1450–1460 (2017). https://doi.org/10.1007/s13198-017-0614-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-017-0614-8