Abstract

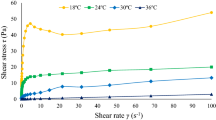

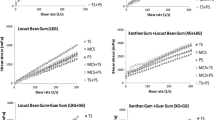

Tree different fermented dairy products obtained by conventional and non-conventional starter cultures were investigated in this paper. Textural and rheological characteristics as well as chemical composition during 21 days of storage were analysed and subsequent data processing was performed by principal component analysis. The analysis of samples` flow behaviour was focused on their time dependent properties. Parameters of Power law model described flow behaviour of samples depended on used starter culture and days of storage. The Power law model was applied successfully to describe the flow of the fermented milk, which had characteristics of shear thinning and non-Newtonian fluid behaviour.

Similar content being viewed by others

References

Abou-Soliman NHI, Sakr SS, Awad S (2017) Physico-chemical, microstructural and rheological properties of camel-milk yogurt as enhanced by microbial transglutaminase. J Food Sci Technol 54:1616. https://doi.org/10.1007/s13197-017-2593-9

Abu-Jdayil B (2003) Modelling the time-dependent rheological behavior of semisolid food stuffs. J Food Eng 57:97–102

Brown SD (1988) Chemometrics: a textbook. In: Massart DL, Vandeginste BGM, Deming SN, Michotte Y, Kaufman L (eds) Elsevier, Amsterdam, 1988. ISBN 0-444-42660-4. Price Dfl 175.00 J Chemometr 2:298–299

De Lorenzi L, Pricl S, Torriano G (1995) Rheological behaviour of low-fat and full-fat stirred yoghurt. Int Dairy J 5:661–671. https://doi.org/10.1016/0958-6946(95)00047-7

Dokic P, Sovilj V, Sefer I, Rasulic G (1999) Thixotropy evaluation by the parameters of flow equation. Acta Period Technol 29–30:67–79

Dolz M, Gonzalez F, Delegido J, Hernandez MJ, Pellicer J (2000) A time-dependent expression for thixotropic areas. Application to Aerosil 200 hydrogels. J Pharm Sci US 89:790–797

Donato L, Alexander M, Dalgleish DG (2007) Acid gelation in heated and unheated milks: interactions between serum protein complexes and the surfaces of casein micelles. J Agric Food Chem 55:4160–4168. https://doi.org/10.1021/jf063242c

Figoni PI, Shoemaker CF (1983) Characterization of time dependent flow properties of mayonnaise under steady shear. J Texture Stud 14:431–442. https://doi.org/10.1111/j.1745-4603.1983.tb00360.x

Gonzalez-Martınez C, Becerra M, Cháfer M, Albors A, Carot JM, Chiralt A (2002) Influence of substituting milk powder for whey powder on yoghurt quality. Trends Food Sci Technol 13:334–340. https://doi.org/10.1016/S0924-2244(02)00160-7

Hrnjez D, Vaštag Ž, Milanović S, Vukić V, Iličić M, Popović L, Kanurić K (2014a) The biological activity of fermented dairy products obtained by kombucha and conventional starter cultures during storage. J Funct Food 10:336–345. https://doi.org/10.1016/j.jff.2014.06.016

Hrnjez D, Vukić V, Milanović S, Iličić M, Kanurić K, Torbica A, Tomić J (2014b) Nutritive aspects of fermented dairy products obtained by kombucha application. Agro Food Ind Hi Tech 25:70–73

IDF 90:1979 (1979) Rennet caseins and caseinates. In: Determination of ash (reference method). Brussels

IDF 20-5:2001 (2001) Determination of the total nitrogen content of milk by the Kjeldahl method. Brussels

IDF 105 (2008) Brussels

Iličić M, Kanurić K, Milanović S, Lončar E, Djurić M, Malbaša R (2012) Lactose fermentation by Kombucha: a process to obtain new milk-based beverages. Rom Biotechnol Lett 17:7013–7021

Iličić MD, Milanović SD, Carić MÐ, Vukić VR, Kanurić KG, Ranogajec MI, Hrnjez DV (2013) The effect of transglutaminase on rheology and texture of fermented milk products. J Texture Stud 44:160–168. https://doi.org/10.1111/jtxs.12008

Iličić MD, Milanović SD, Carić MÐ, Dokić LP, Kanurić KG (2014) Effect of transglutaminase on texture and flow properties of stirred probiotic yoghurt during storage. J Texture Stud 45:13–19. https://doi.org/10.1111/jtxs.12038

ISO6731:2010-IDF21:2010 (2010) Milk, cream and evaporated milk. In: Determination of the total solids content (reference Method). Brussels

Kadegowda AK, Piperova LS, Erdman RA (2008) Principal component and multivariate analysis of milk long-chain fatty acid composition during diet-induced milk fat depression. J Dairy Sci 91:749–759. https://doi.org/10.3168/jds.2007-0265

Kim NS, Lee JH, Han KM, Kim JW, Cho S, Kim J (2014) Discrimination of commercial cheeses from fatty acid profiles and phytosterol contents obtained by GC and PCA. Food Chem 143:40–47. https://doi.org/10.1016/j.foodchem.2013.07.083

Koocheki A, Razavi SMA (2009) Effect of concentration and temperature on flow properties of alyssum homolocarpum seed gum solutions: assessment of time dependency and thixotropy. Food Biophys 4:353–364

Lee W, Lucey J (2010) Formation and physical properties of yogurt. Asian Australas J Anim 23:1127–1136

Lončar E, Kanurić K, Malbaša R, Đurić M, Milanović S (2013) Kinetics of saccharose fermentation by Kombucha. Chem Ind Chem Eng Q 20:345–352

Lucey JA (2004) Formation, structural properties and rheology of acid-coagulated milk gels. In: Fox PF, McSweeney PLH, Timothy PG (eds) Cheese: chemistry, physics and microbiology. Academic Press, Cambridge, pp 105–122. https://doi.org/10.1016/S1874-558X(04)80064-2

Malbaša RV, Milanović SD, Lončar ES, Djurić MS, Carić MD, Iličić MD, Kolarov L (2009) Milk-based beverages obtained by Kombucha application. Food Chem 112:178–184. https://doi.org/10.1016/j.foodchem.2008.05.055

Malbaša R, Jevrić L, Lončar E, Vitas J, Podunavac-Kuzmanović S, Milanović S, Kovačević S (2014) Chemometric approach to texture profile analysis of kombucha fermented milk products. J Food Sci Technol 52:5968–5974

Marsh AJ, O’Sullivan O, Hill C, Ross RP, Cotter PD (2014) Sequence-based analysis of the bacterial and fungal compositions of multiple kombucha (tea fungus) samples. Food Microbiol 38:171–178. https://doi.org/10.1016/j.fm.2013.09.003

Mudgil D, Barak S, Khatkar BS (2017) Texture profile analysis of yogurt as influenced by partially hydrolyzed guar gum and process variables. J Food Sci Technol 54:3810. https://doi.org/10.1007/s13197-017-2779-1

Pakseresht S, Mazaheri Tehrani M, Razavi SMA (2017) Optimization of low-fat set-type yoghurt: effect of altered whey protein to casein ratio, fat content and microbial transglutaminase on rheological and sensorial properties. J Food Sci Technol 54:2351. https://doi.org/10.1007/s13197-017-2675-8

Paseephol T, Small DM, Sherkat F (2008) Rheology and texture of set yogurt as affected by inulin addition. J Texture Stud 39:617–634. https://doi.org/10.1111/j.1745-4603.2008.00161.x

Pasha C, Reddy G (2005) Nutritional and medicinal improvement of black tea by yeast fermentation. Food Chem 89:449–453. https://doi.org/10.1016/j.foodchem.2004.02.054

Rao MA (2007) Flow and functional models for rheological properties of fluid foods. In: Rheology of fluid and semisolid foods: principles and applications. Springer, Boston, MA, pp 27–58. https://doi.org/10.1007/978-0-387-70930-7_2

Roussin MR (1996) Analyses of kombucha ferments. Information Resources, LC, Salt Lake City

Skriver A, Holstborg J, Qvist KB (1999) Relation between sensory texture analysis and rheological properties of stirred yogurt. J Dairy Res 66:609–618

Skrzypczak K, Gustaw W, Szwajgier D et al (2017) κ-Casein as a source of short-chain bioactive peptides generated by Lactobacillus helveticus. J Food Sci Technol 54:3679. https://doi.org/10.1007/s13197-017-2830-2

Sreeramulu G, Zhu Y, Knol W (2000) Kombucha fermentation and its antimicrobial activity. J Agric Food Chem 48:2589–2594. https://doi.org/10.1021/jf991333m

Sreeramulu G, Zhu Y, Knol W (2001) Characterization of antimicrobial activity in Kombucha fermentation. Acta Biotechnol 21:49–56

Tárrega A, Durán L, Costell E (2004) Flow behaviour of semi-solid dairy desserts. Effect of temperature. Int Dairy J 14:345–353

Teoh AL, Heard G, Cox J (2004) Yeast ecology of Kombucha fermentation. Int J Food Microbiol 95:119–126. https://doi.org/10.1016/j.ijfoodmicro.2003.12.020

Vukic V, Hrnjez D, Kanuric K, Milanovic S, Iličic M, Torbica A, Tomic J (2014) The effect of kombucha starter culture on the gelation process, microstructure and rheological properties during milk fermentation. J Texture Stud 45:261–273

Acknowledgments

Authors would like to thank the Ministry of Education, Science and Technological Development of Republic of Serbia for their financial support of research presented in this article, Project No. 46009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vukić, D.V., Vukić, V.R., Milanović, S.D. et al. Modeling of rheological characteristics of the fermented dairy products obtained by novel and traditional starter cultures. J Food Sci Technol 55, 2180–2188 (2018). https://doi.org/10.1007/s13197-018-3135-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3135-9