Abstract

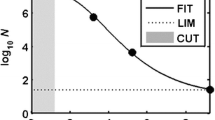

Sigmoidal microbial survival curves are observed in high-pressure carbon dioxide (HPCD) pasteurization treatments. The objectives of this study were to use the Gompertz primary model to describe the inactivation in apple juice of the pathogen Escherichia coli CGMCC1.90 and to apply probabilistic engineering to select HPCD treatments meeting at least 5 log10 reductions (SV ≥ 5) at 95% confidence. This required secondary models for the temperature (T, °C) and pressure (P, MPa) dependence of the Gompertz model parameters. The expressions \( b\left( {T,P} \right) = 14.21 + 0.011P - 0.67T + 0.0085T^{2} \) and \( c\left( {T,P} \right) = - 0.10 + 0.0023P + 0.0037T \) selected using goodness-of-fit measures and assessments based on Akaike and Bayesian information criteria were consistent with proposed mechanistic models for HPCD bactericidal effects. Monte Carlo simulations accounting for the variability and uncertainty of the parameter b and c estimates were used to predict SV values for a given time, temperature and CO2 pressure combination and desired confidence boundary. A similar approach used to estimate process times meeting SV ≥ 5 at 95% confidence for a given temperature and CO2 pressure combination, showed that HPCD processes met this requirement only for relatively long processing times, i.e., 35–124 min in the experimental range of 32–42 °C and 10–30 MPa. Therefore, further HPCD research is required to reduce processing time.

Similar content being viewed by others

References

Center for Food Safety and Applied Nutrition (CFSAN) (2002) Exemptions from the warning label requirement for juice: recommendations for effectively achieving a 5-log pathogen reduction, final guidance vol 2002. Guidance for industry, vol Oct-7. U.S. Department of Health and Human Services, Food and Drug Administration, Center for Food Safety and Applied Nutrition, Silver Spring

Chotyakul N, Velazquez G, Torres JA (2011) Assessment of the uncertainty in thermal food processing decisions based on microbial safety objectives. J Food Eng 102:247–256. doi:10.1016/j.jfoodeng.2010.08.027

Cruz RMS, Rubilar JF, Ulloa PA, Torres JA, Vieira MC (2011) New food processing technologies: development and impact on the consumer acceptability. In: Columbus F (ed) Food quality: control, analysis and consumer concerns. Nova Science Publishers, New York, pp 555–584

Damar S, Balaban MO (2006) Review of dense phase CO2 technology: microbial and enzyme inactivation, and effects on food quality. J Food Sci 71:R1–R11

Dillow AK, Dehghani F, Hrkach JS, Foster NR, Langer R (1999) Bacterial inactivation by using near- and supercritical carbon dioxide. Proc Natl Acad Sci 96:10344–10348

Erkmen O (2001) Mathematical modeling of Escherichia coli inactivation under high-pressure carbon dioxide. J Biosci Bioeng 92:39–43. doi:10.1016/s1389-1723(01)80196-1

Ferrentino G, Ferrari G, Poletto M, Balaban MO (2008) Microbial inactivation kinetics during high-pressure carbon dioxide treatment: nonlinear model for the combined effect of temperature and pressure in apple juice. J Food Sci 73:E389–E395. doi:10.1111/j.1750-3841.2008.00920.x

Ferrentino G, Bruno M, Ferrari G, Poletto M, Balaban MO (2009) Microbial inactivation and shelf life of apple juice treated with high pressure carbon dioxide. J Biol Eng 3:1–9. doi:10.1186/1754-1611-3-3

Ferrentino G, Balzan S, Spilimbergo S (2013) Supercritical carbon dioxide processing of dry cured ham spiked with Listeria monocytogenes: inactivation kinetics, color, and sensory evaluations. Food Bioprocess Technol 6:1164–1174

Food and Drug Administration (2009) FDA Food Code 2009: Annex 3—public health reasons/administrative guidelines—chapter 3, food. Department of Public Health Service, Food and Drug Administration, U.S. Department of Health and Human Services. http://www.fda.gov/Food/FoodSafety/RetailFoodProtection/FoodCode/FoodCode2009/ucm189211.htm. Accessed 14 Mar 2017

Garcia-Gonzalez L et al (2007) High pressure carbon dioxide inactivation of microorganisms in foods: the past, the present and the future. Int J Food Microbiol 117:1–28. doi:10.1016/j.ijfoodmicro.2007.02.018

Gayán E, Serrano M, Torres J, Álvarez I, Condón S (2012) Optimization of a combined UV-heat treatment for apple juice pasteurization based on risk assessment tools. In: Martínez A et al (eds) 2nd workshop on food safety technologies and innovations applied to food safety (July 5–6, 2012), Valencia, Spain. Sicura and Food Safety Working Group of the International Commission of Agricultural and Biosystems Engineering (FSWG-CIGR), pp 57–61

Gayán E, Torres JA, Álvarez I, Condón S (2014) Selection of process conditions by risk assessment for apple juice pasteurization by UV-heat treatments at moderate temperatures. J Food Prot 77:207–215

Hong SI, Pyun YR (1999) Inactivation kinetics of Lactobacillus plantarum by high pressure carbon dioxide. J Food Sci 64:728–733

Huang H, Zhang Y, Liao H, Hu X, Wu J, Liao X, Chen F (2009) Inactivation of Staphylococcus aureus exposed to dense-phase carbon dioxide in a batch system. J Food Process Eng 32:17–34

Jones RP, Greenfield PF (1982) Effect of carbon dioxide on yeast growth and fermentation. Enzyme Microb Technol 4:210–223

Liao H, Hu X, Liao X, Chen F, Wu J (2007) Inactivation of Escherichia coli inoculated into cloudy apple juice exposed to dense phase carbon dioxide. Int J Food Microbiol 118:126–131. doi:10.1016/j.ijfoodmicro.2007.06.018

Liao H, Zhang Y, Hu X, Liao X, Wu J (2008) Behavior of inactivation kinetics of Escherichia coli by dense phase carbon dioxide. Int J Food Microbiol 126:93–97. doi:10.1016/j.ijfoodmicro.2008.05.008

Lin HM, Yang Z, Chen LF (1992) An improved method for disruption of microbial cells with pressurized carbon dioxide. Biotechnol Prog 8:165–166

Lin HM, Yang Z, Li F-C (1993) Inactivation of Leuconostoc dextranicum with carbon dioxide under pressure. Chem Eng J 52:B29–B34

Meyssami B, Balaban MO, Teixeira AA (1992) Prediction of pH in model systems pressurized with carbon dioxide. Biotechnol Prog 8:149–154

Peleg M (2002) Simulation of E. coli inactivation by carbon dioxide under pressure. J Food Sci 67:896–901. doi:10.1111/j.1365-2621.2002.tb09425.x

R Development Core Team (2010) R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna

Salgado D, Torres JA, Welti-Chanes J, Velazquez G (2011) Effect of input data variability on estimations of the equivalent constant temperature time for microbial inactivation by HTST and retort thermal processing. J Food Sci 76:E495–E502

Serment-Moreno V, Barbosa-Cánovas G, Torres JA, Welti-Chanes J (2014) High pressure processing: kinetic models for microbial and enzyme inactivation. Food Eng Rev 6:56–88. doi:10.1007/s12393-014-9075-x

Serment-Moreno V, Deng K, Wu X, Welti-Chanes J, Velazquez G, Torres JA (2015a) Pressure effects on the rate of chemical reactions under the high pressure and high temperature conditions used in pressure-assisted thermal processing. In: Cheung PCK, Mehta BM (eds) Handbook of food chemistry, vol 1. Springer, Berlin, pp 1–23. doi:10.1007/978-3-642-41609-5_5-1

Serment-Moreno V, Fuentes C, Torres JA, Welti-Chanes J (2015b) Evaluation of high pressure processing kinetic models for microbial inactivation using standard statistical tools and information theory criteria, and the development of generic time-pressure functions for process design. Food Bioprocess Technol 8:1244–1257

Serment-Moreno V, Fuentes C, Guerrero Beltran JA, Torres JA, Welti-Chanes J (2017) A Gompertz model approach to microbial inactivation kinetics by high pressure processing (HPP) incorporating come-up time effects, initial counts, microbial quantification limit and detection limit. Food Bioprod Process 10:1495–1508

Spilimbergo S (2002) A study about the effect of dense CO2 on microorganisms. University of Padova, Padova

Spilimbergo S, Elvassore N, Bertucco A (2002) Microbial inactivation by high-pressure. J Supercrit Fluids 22:55–63

Stahl E, Quirin K-W, Gerard D (2012) Dense gases for extraction and refining. Springer, New York

U.S. Food and Drug Administration (2015) Guidance for industry: juice HACCP hazards and controls guidance first edition; final guidance. U.S. Department of Health and Human Services. www.fda.gov/Food/GuidanceRegulation/GuidanceDocumentsRegulatoryInformation/Juice/ucm072557.htm

Vose D (2008) Choice of model structure—how Monte Carlo simulation works. In: Risk analysis: a quantitative guide, chapter 4.4, 2nd edn. Wiley, Chichester, pp 57–64

Zhang J, Davis TA, Matthews MA, Drews MJ, LaBerge M, An YH (2006) Sterilization using high-pressure carbon dioxide. J Supercrit Fluids 38:354–372

Zhou Y-G (2015) Personal communication. China General Microbiological Culture Collection Center (CGMCC), Institute of Microbiology, Chinese Academy of Sciences, Beijing

Zwietering MH, Jongenburger I, Rombouts FM, van’t Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56:1875–1881

Acknowledgements

This project was supported by Formula Grants 2011-31200-06041/2012-31200-06041328 from the USDA National Institute of Food and Agriculture, Fondo Nacional de Ciencia y Tecnología de Chile (FONDECYT Grant 1151025), Research Office of Universidad Andrés Bello (DI-641-15/R 2015), and Tecnológico de Monterrey (Research chair funds GEE 1A01001375).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Deng, K., Serment-Moreno, V., Welti-Chanes, J. et al. Inactivation model and risk-analysis design for apple juice processing by high-pressure CO2 . J Food Sci Technol 55, 258–264 (2018). https://doi.org/10.1007/s13197-017-2933-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2933-9