Abstract

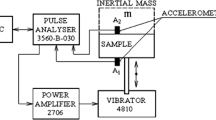

Storage conditions of pear affect its subsequent softening process and shelf life. Measurements of firmness have traditionally been carried out according to the Magness Taylor (MT) procedure; using a texture analyzer or penetrometer in reference texture tests. In this study, a non-destructive method using Laser Doppler vibrometer (LDV) technology was used to estimate texture firmness of pears. This technique was employed to detect responses to imposed vibration of intact fruit using a shaker. Vibration transmitted through the fruit to the upper surface was measured by LDV. A fast Fourier transform algorithm was used to process response signals and the desired results were extracted. Multiple Linear Regression models using fruit density and four parameters obtained from modal tests showed better correlation (R2 = 0.803) with maximum force in Magness Taylor test compared to the models that used only modal parameters (R2 = 0.798). The best polynomial regression models for pear firmness were based on elasticity index (EI) and damping ratio (η) with R2 = 0.71 and R2 = 0.64, respectively. This study shows the capability of the LDV technique and the vibration response data for predicting ripeness and modeling pear firmness and the significant advantage for commercially classifying of pears based on consumer demands.

Similar content being viewed by others

Abbreviations

- LDV:

-

Laser doppler vibrometer

- EI:

-

Elasticity index

- fn:

-

Resonance frequency

- m:

-

Mass

- RF2 :

-

Second resonance frequency

- f1 and f2 :

-

Frequencies determined at 3 dB below peak resonance

- η:

-

Damping ratio

- γ:

-

Density

- φ:

-

Phase shift

- Hz:

-

Hertz

- FMT :

-

Magness Taylor firmness

- R2 :

-

Coefficient of determination

- PCA:

-

Principal Component Analysis

- MLR:

-

Multiple linear regression

- ANOVA:

-

Analysis of variance

References

Abbott JA, Massie DR (1998) Nondestructive sonic measurement of kiwifruit firmness. J Am Soc Hortic Sci 123:317–322

Abdolahi H (2007) An overview of the status of pear production in Iran. Division of Horticultural Research Technical publications of Seed and Plant Improvement Institute, Karaj

Cooke JR (1972) An interpretation of the resonant behavior of intact fruits and vegetables. Trans ASAE 15(6):1075–1080

De Belie N, Schotte S, Lammertyn J, Nicolai B, De Baerdemaeker J (2000) Firmness changes of pear fruit before and after harvest with acoustic impulse response technique. J Agric Eng Res 77(2):183–191

Landahl S, Jacksok PT, De Baerdemaeker J (2003) Firmness of developing apples on the tree and shortly after harvest measured with the acoustic impulse response. Acta Hortic 600:63–70

Langenakens J, Vandewalle X, De Baerdemaeker J (1997) Influence of global shape and internal structure of tomatoes on the resonant frequency. J Agric Eng Res 66:41–49

Mohsenin NN (1978) Physical properties of plant and animal materials, 1st edn. Gordon and Breach, New York

Molina-Delgado D, Alegre S, Barreiro P, Valero C, Ruiz-Altisent M, Recasens I (2009) Addressing potential sources of variation in several non-destructive techniques for measuring firmness in apples. Biosys Eng 104(1):33–46

Motomura Y, Nagao T, Sakurai N (2004) Nondestructive and noncontact measurement of flesh firmness of 6 apple cultivars by Laser Dopplar Vibrometer (LDV). J Jpn Soc Food Sci Technol 51(9):483–490

Muramatsu N, Sakurai N, Yamamoto R, Tanaka K, Asakura T, Ishikawa-Takano Y, Nevins DJ (1997) Critical comparison of an accelerometer and a laser Doppler vibrometer for measuring fruit firmness. HortTechnology 7:434–438

Muramatsu N, Sakurai N, Wada N, Yamamoto R, Takahara T, Ogata T, Tanaka K, Asakura T, Ishikawa-Takano Y, Nevins DJ (1999) Evaluation of fruit tissue texture and internal disorders by laser Doppler detection. Postharvest Biol Technol 15(1):83–88

Muramatsu N, Sakurai N, Wada N, Yamamoto R, Tanaka K, Asakura T, Ishikawa-Takano Y, Nevins DJ (2000) Remote sensing of fruit textural changes with a laser Doppler vibrometer. J Am Soc Hortic Sci 125(1):120–127

Murayama H, Takahashi T, Honda R, Fukushima T (1998) Cell wall changes in pear fruit softening on and off the tree. Postharvest Biol Technol 14:143–149

Murayama H, Konno I, Terasaki S, Yamamoto R, Sakurai N (2006) Nondestructive method for measuring fruit ripening of ‘La France’ pears using a laser Doppler vibrometer. J Jpn Soc Hortic Sci 75:79–84

Narsaiah K, Jha SN, Bhardwaj R, Sharma R, Kumar R (2011) Optical biosensors for food quality and safety assurance. J Food Sci Technol. doi:10.1007/s13197-011-0437-6

Taniwaki M, Hanada T, Sakurai N (2009a) Postharvest quality evaluation of “Fuyu” and “Taishuu” persimmons using a nondestructive vibrational method and an acoustic vibration technique. Postharvest Biol Technol 51(1):80–85

Taniwaki M, Hanada T, Tohro M, Sakurai N (2009b) Non-destructive determination of the optimum eating ripeness of pears and their texture measurements using acoustical vibration techniques. Postharvest Biol Technol 51(3):305–310

Taniwaki M, Takahashi M, Sakurai N (2009c) Determination of optimum ripeness for edibility of postharvest melons using nondestructive vibration. Food Res Int 42:137–141

Taniwaki M, Tohro M, Sakurai N (2010) Measurement of ripening speed and determination of the optimum ripeness of melons by a nondestructive acoustic vibration method. Postharvest Biol Technol 56(1):101–103

Terasaki S, Sakurai N, Yamamoto R, Wada N, Nevins DJ (2001a) Changes in cell wall polysaccharides of kiwifruit and the visco-elastic properties detected by a laser Doppler method. J Jpn Soc Hortic Sci 70:572–580

Terasaki S, Wada N, Sakurai N, Muramatsu N, Yamamoto R, Nevins DJ (2001b) Nondestructive measurement of kiwifruit ripeness using a laser Doppler vibrometer. Trans ASAE 44:81–87

Terasaki S, Sakurai N, Zebrowski J, Murayama H, Yamamoto R, Nevins DJ (2006) Laser Doppler vibrometer analysis of changes in elastic properties of ripening ‘La France’ pears after postharvest storage. Postharvest Biol Technol 42:198–207

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oveisi, Z., Minaei, S., Rafiee, S. et al. Application of vibration response technique for the firmness evaluation of pear fruit during storage. J Food Sci Technol 51, 3261–3268 (2014). https://doi.org/10.1007/s13197-012-0811-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0811-z