Abstract

Gmelina (Gmelina arborea Roxb.) is one of several species of wood found in the community forest that grows in Indonesia, especially in the West Java province. To obtain maximum benefit results from the community forest, more than timber needs to be used. Scientists need to find alternative uses for the wood bark waste. The objective of this research was to study the characteristics of organic nanoparticles produced from Gmelina wood bark (GWB), using a conventional balls milling method. GWB an organic waste material from the community forest was converted into nanoparticles using a conventional balls milling method for 96 h and was then filtered using four sieve types (T77, T90, T120 and T200). The nanoparticle was characterized and studied for its particle size, morphology and particle size, chemical components, functional groups and crystallinity using transmission electron microscopy (TEM), scanning electron microscopy (SEM), scanning electron microscopy that extended with energy dispersive X-ray spectroscopy (SEM–EDS), Fourier transform infrared spectroscopy (FTIR) and X-ray diffraction (XRD). The nanoparticle sizes measured using TEM analysis was less than 100 nm, produced from T90 sieve type, whereas based on a SEM analysis was found to be 104–254 nm, 71–104 nm, 33–47 nm and 33–38 nm; produced from T77, T90, T120 and T200 sieve types, respectively. The proportions of nanoparticle sizes were 11.2%, 82.9%, 3.5% and 0.6%; produced from T77, T90, T120 and T200 sieve types, respectively, and the remaining (1.8%) nanoparticles was retained on T77 sieve type. The chemical components obtained from SEM–EDS analysis were carbon, oxygen, potassium and calcium. The FTIR analysis shows the presence of C–O–C in plane and symmetric band at 829 cm−1 in the nanoparticle produced from T200 sieve type, while there is no C–O–C from the nanoparticle produced from T77, T90 and T120 sieve types. The crystalline structure obtained from XRD analysis found was calcium oxalate hydrate (C2CaO4·H2O) with crystalline diameter size of 20 nm. This result is similar, either produced by T77 or T200 sieve types.

Similar content being viewed by others

References

Abdul Khalil HPS, Fizree HM, Jawaid M, Alattas OS (2011) Preparation and characterization of nano-structured materials from oil palm ash: a bio-agricultural waste from oil palm mill. BioResources 6:4537–4546

Allouche J (2013) Synthesis of organic and bioorganic nanoparticles: an overview of the preparation methods. nanomaterials: a danger or a promise? In: Brayner R, Fievet F, Coradin T (eds) A chemical and biological perspective. Springer, London, pp 27–74

Buamscha MG, Altland JE, Sullivan DM, Horneck DA, Cassidy J (2007) Chemical and physical properties of douglas fir bark relevant to the production of container plants. HortScience 42(5):1281–1286

Buzea C, Pacheco II, Robbie K (2007) Nanomaterials and nanoparticles: sources and toxicity. Biointerphases 2:MR17–MR172

Carter FL, Cario AM, Stanley JB (1978) Termiticidal components of wood extracts: 7-methyljuglone from diospyros virginia. J Agric Food Chem 26(4):869–873

Chow S, Steiner PR (1979) Comparisons of the cure of phenol-formaldehyde novolac and resol systems by differential scanning calorimetry. J Appl Polym Sci 23(7):1973–1985

Clemons CM, Caufield DF (2005) Wood flour. In: Xanthos M (ed) Functional fillers for plastics. Wiley, Weinheim, pp 249–270

Eberhardt TL, Reed KG (2005) Grinding and classification of pine bark for use as plywood adhesive filler, peer reviewed. In: Appita Pre Symposium, pp 109–113

Eberhardt TL, Reed KG (2006) Strategies for improving the performance of plywood adhesive mix fillers from southern yellow pine bark. For Prod J 56(10):64–68

Eberhardt TL, Reed KG, So CL (2009) Partitioning of pine bark components to obtain a value-added product for plywood manufacture. In: Hse CY, Jiang Z, Kuo, ML (eds) Advanced biomass science and technology for bio-based products., developed from a symposium sponsored by Chinese Academy of Forestry & USDA Forest Service, Southern Research Station, pp 302–309

Falah S, Katayama T, Suzuki T (2008) Chemical constituents from Gmelina arborea bark and their antioxidant activity. J Wood Sci 54:483–489

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres, Fourier transform—materials analysis. In: Salih Salih (ed) ISBN: 978-953-51-0594-7, InTech, pp 45–68. (http://www.intechopen.com/books/fourier-transform-materials-analysis/fourier-transform-infraredspectroscopy-for-natural-fibres)

Garside P, Wyeth P (2003) Identification of cellulosic fibres by FTIR spectroscopy: thread and single fibre analysis by attenuated total reflectance. Stud Conserv 48(4):269–275

Hagerman AE (2012) What is Tannin? The Tannin Handbook. http://chemistry.muohio.edu/hagerman. Accessed 15 Feb 2012

Harkin JM, Rowe JW (1971) Bark and its Possible Uses. Res. Note FPL-091. U.S.Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, Wis. In Cooperation with the University of Wisconsin, p 56

Harkin JM, Rowe JW (1971) Bark and its possible uses. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, Wisconsin. In: Cooperation with the University of Wisconsin

Japanese Agricultural Standard [JAS] (2008) Japanese agricultural standard for plywood. The notification no. 1751 of Ministry of Agriculture, Forestry and Fisheries dated 2 Dec 2008

Jasni, Pari G, Ruliadi, Kosasih K, Sutrisno (2001) The potential use of tannin as a preservative for wood and Rattan. In: Proceedings of the fifth international conference on the development of wood science, Wood Technology and Forestry (ICWSF), Ljubljana, Slovenija, pp 61–67

Kampeerapappun P (2012) Preparation characterization and antimicrobial activity of electrospun nanofibers from cotton waste fibers. Chiang Mai J Sci 39(4):712–722

Khan MA, Ashraf SM, Malhotra VP (2004) Eucalyptus bark lignin substituted phenol formaldehyde adhesives: a study on optimalization of reaction parameters and characterization. J Appl Polym Sci 92:3514–3523

Marchessault RH (1962) Application of infra-red spectroscopy to cellulose and wood polysaccharides. Pure Appl Chem 5(1–2):107–130

Marra AA (1992) Characteristics and compostion of adhesives. In: Technology of wood bonding: principles in practice, 1 ed. Van Nostrand Reinhold, New York, pp 76–80

Miles PD, Smith WB (2009) Specific Gravity and other properties of wood and bark for 156 tree species found in North America. Res. Note NRS-38. Newtown Square, PA: U.S. Department of Agriculture, Forest Service, Northern Research Station, p 35

Ministry of Forestry of the Republic of Indonesia (2010) Opportunities of community forest investment in Java (in Indonesia). Directorate General for Development of Watershed Management and Social Forestry, Jakarta, p 66

Overney R (2012) Nanothermodynamics and nanoparticle synthesis part 1: nanoparticles and synthesis. NME 498. http://courses.washington.edu/overney/NME498_Material/NME498_Lectures/Lecture%20on%20Thermo%20and%20Nanoparticles%20v5.pdf. Accessed 19 May 2012

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:10

Patterson AL (1939) The scherrer formula for X-ray particle size determination. Phys Rev 56:978–982

Pizzi A (1994) Tannin-based wood adhesives. In: Pizzi A (ed) Advanced wood adhesives technology. Marcel Dekker Inc, New York, pp 149–215

Poletto M, Zattera AJ, Santana RMC (2012a) Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. J Appl Polym Sci 126:E336–E343

Poletto M, Zattera AJ, Forte MM, dan Santana RMC (2012b) Thermal decomposition of wood: influence of wood components and cellulose crystallite size. Bioresour Technol 109:148–153

Poletto M, Zattera AJ, dan Santana RMC (2012c) Thermal decomposition of wood: kinetics and degradation mechanisms. Bioresour Technol 126:7–12

Purwasasmita BS, Tafwidli F, Septawendar R (2013a) Synthesis and characterization of carbon nanocoil with catalytic graphitization process of (Oryza Sativa) pulp precursors. J Aust Ceram Soc 49(1):119–126

Purwasasmita BS, Larasati LD, Septawendar R, Nugraha AB, Aufan MR, Sosiati H (2013b) Synthesis and characterization of zirconia crystal using base hot water treatment (BHWT) method. J Aust Ceram Soc 49(2):89–94

Subyakto, Prasetya B (2003) Direct utilization of acacia wood bark powder as an adhesive of particle board. J Trop Wood Sci Technol 1(1):20–25

Subyakto, Suryanegara L, Gopar M, Prasetiyo KW (2005) Utilization of Acacia Wood Bark (Acacia mangium Willd) for particle board with low levels of phenol formaldehyde. J Trop Wood Sci Technol 3(2):20–23

Sutrisno, Syamsudin TS, Alamsyah EM, Purwasasmita BS (2014) Synthesis of bio-based nanomaterial from surian (Toona sinensis Roem) wood bark using conventional balls milling and its characterization. J Biol Sci 14(3):204–212

Sutrisno, Syamsudin TS, Alamsyah EM, Purwasasmita BS (2015) Synthesis and characterization of bio-based nanomaterials from Jabon (Anthocephalus cadamba (Roxb.) Miq) wood bark: an organic waste material from community forest. J Math Fund Sci 47(2):205–218

Sutrisno, Alamsyah EM, Sulistyawati E, Suheri A (2018) The potential use of wood waste ash nanofiller for improvement of laminated veneer lumber production made from Jabon (Anthocephalus cadamba). J Indian Acad Wood Sci 15(2):126–131

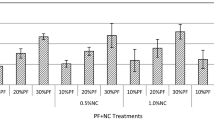

Sutrisno, Widyorini R, Syamsudin TS, Alamsyah EM, Purwasasmita BS (2020) Bonding strength of plywood bonded using phenol formaldehyde mixed with wood bark powder nanofiller. J Indian Acad Wood Sci 17(1):21–33

Torrey KS (2001) Influence of thermally conductive fillers on the physical properties of waferboard. Master Sci Chem Eng Mich Technol Univ 298:2001

Umer A, Naveed S, Ramzan N, Rafique MS (2012) Selection of a suitable method for the synthesis of copper nanoparticles. Brief Rep Rev 7:1–18

Acknowledgements

The authors would like to thank the Directorate of Research and Community Services, Ministry of Research Technology and Higher Education of the Republic of Indonesia for their financial support under the research scheme of Basic Research for the Fiscal Year 2019.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sutrisno, Alamsyah, E.M., Syamsudin, T.S. et al. The potential using of organic nanoparticles synthesized from Gmelina (Gmelina arborea Roxb.) wood bark as nanofiller of wood adhesive: physical, chemical and thermal properties. J Indian Acad Wood Sci 17, 165–175 (2020). https://doi.org/10.1007/s13196-020-00269-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13196-020-00269-7