Abstract

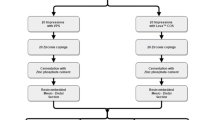

Accuracy of the fit of the restoration has always remained as one of the primary factors in determining success of the restoration. A well fitting restoration needs to be accurate both along its margins and internal surface. This study was conducted to comparatively evaluate the marginal gap and internal gap of cobalt–chromium (Co–Cr) copings fabricated by conventional casting procedures and with direct metal laser sintering (DMLS) technique. Among the total of 30 test samples 10 cast copings were made from inlay casting wax and 10 from 3D printed resin pattern. 10 copings were obtained from DMLS technique. All the 30 test samples were then cemented sequentially on stainless steel model using pressure indicating paste and evaluated for vertical marginal gap in 8 predetermined reference areas. All copings were then removed and partially sectioned and cemented sequentially on same master model for evaluation of internal gap at 4 predetermined reference areas. Both marginal gap and internal gap were measured in microns using video measuring system (VMS2010F). The results obtained for both marginal and internal gap were statistically analyzed and the values fall within the clinically acceptable range. The DMLS technique had an edge over the other two techniques used, as it exhibited minimal gap in the marginal region which is an area of chief concern.

Similar content being viewed by others

References

Fusayama T (1959) Factors and technique of precision casting Part I. J Prosthet Dent 9(3):468–485

Schwartz IS (1986) A review of methods and techniques to improve the fit of cast restorations. J Prosthet Dent 56:279–283

Ucar Y, Akova T, Akyil MS, Brantley WA (2009) Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co–Cr crowns. J Prosthet Dent 102:253–259

Plekavich EJ, Joncas JM (1983) The effect of impression-die systems on crown margins. J Prosthet Dent 49(6):772–776

Grenade C, Malnjot A, Vanheusden A (2011) Fit of single tooth zirconia copings: comparison between various manufacturing process. J Prosthet Dent 105(4):249–255

Holmes JR, Bayne SC, Holland GA, Sulik WD (1989) Consideration in measurement of marginal fit. J Prosthet Dent 62:405–408

Tan PL, Gratton DG, Arnold AMD, Holmes DC (2008) An in vitro comparison of vertical marginal gaps of CAD/CAM titanium and conventional cast restorations. J Prosthet Dent 17:378–383

Dedmon HW (1985) The relationship between open margins and marginal designs on full cast crowns made by commercial dental laboratories. J Prosthet Dent 53(4):463–466

Holden JE, Goldstein GR, Hittleman EL, Clark EA (2009) Comparison of the marginal fit of pressable ceramic to metal ceramic restorations. J Prosthet Dent 18:645–648

Ushiwata O, de Moraes JV (2000) Method for marginal measurements of restorations: accessory device for toolmarks microscope. J Prosthet Dent 83:362–366

Blackman R, Baez R, Barghi N (1992) Marginal accuracy and geometry of cast titanium copings. J Prosthet Dent 67:435–440

Marsaw FA, de Rijk WG, Hesby RA, Hinman RW, Pelleu GB Jr (1984) Internal volumetric expansion of casting investments. J Prosthet Dent 52(3):361–366

Milan FM, Consani S, Sobrinho CL, Sinhoreti MA, Sousa-Neto MD, Knowles JC (2004) Influence of casting methods on marginal and internal discrepancies of complete cast crowns. Braz Dent J 15:127–132

Ogura H, Raptis CN, Asgar K (1981) Inner surface roughness of complete cast crowns made by centrifugal casting machines. J Prosthet Dent 45(5):529–535

White SN, Zhaokun Y, Tom JF, Sanngsurasak S (1995) In vivo marginal adaptation of cast crowns luted with different cements. J Prosthet Dent 74(1):25–32

Iglesias A, Powers JM, Pierpont HP (1996) Accuracy of wax, autopolymerized and light polymerized resin pattern material. J Prosthodont 5(3):201–205

Viennot S, Dalard F, Malquarti G, Grosgogeat B (2006) Combination fixed and removal prostheses using a CoCr alloy: a clinical report. J Prosthet Dent 96:100–103

Khamis E, Seddik M (1995) Corrosion evaluation of recasting non-precious dental alloys. Int Dent J 45(3):209–217

Blanco-Dalmau L, Carrasquillo-Alberty H, Parra JS (1984) A study of nickel allergy. J Prosthet Dent 52(1):116–119

Tara MA, Eschbach S, Bohlsen F, Kern M (2011) Clinical outcome of metal-ceramic crowns fabricated with laser-sintering technology. Int J Prosthodont 24:46–48

Wataha JC (2002) Alloys for prosthodontic restorations. J Prosthet Dent 87:351–363

Wiltshire WA, Ferreira MR, Ligthelm AL (1996) Allergies to dental materials. Quintessence Int 27(8):513–520

Ibrahim D, Broilo TL, Heitz C, de Oliveira MG, de Oliveira HW, Nobre SM, Dos Santos Filho JH, Silva DN (2009) Dimensional error of selective laser sintering, three-dimensional printing and polyjet models in the reproduction of mandibular anatomy. J Craniomaxillofac Surg 37:167–173

Iwai T, Komine F, Kobayashi K, Saito A, Matsumura H (2008) Influence of convergence angle and cement space on adaptation of zirconium dioxide ceramic copings. Acta Odontol Scand 66(4):214–218

Quante K, Ludwig K, Kern M (2008) Marginal and internal fit of metal–ceramic crowns fabricated with laser melting technology. Dent Mater 24(10):1311–1315

Yau H-T, Hsu C-Y, Peng H-L, Pai C-C (2008) Computer-aided framework design for digital dentistry. Comput Aided Des Appl 5(5):667–675

Groten M, Axmann D, PrÖbster L, Weber H (2000) Determination of the minimum number of marginal gap measurements required for practical in vitro testing. J Prosthet Dent 83(1):40–49

Palomo F, Peden J (1976) Periodontal consideration of restorative procedures. J Prosthet Dent 36:387–393

Lacy AM, Fukui H, Jendresen MD (1983) Three factors affecting investment setting expansion and casting size. J Prosthet Dent 49(1):52–58

Hunter AJ, Hunter AR (1990) Gingival crown margin configurations: a review and discussion. Part I: Terminology and widths. J Prosthet Dent 64(5):548–552

Beuer F, Aggstaller H, Richter J, Edelhoff D, Gernet W (2009) Influence of preparation angle on marginal and internal fit of CAD/CAM-fabricated zirconia crown copings. Quintessence Int 40(3):243–250

Bottino MA, Valandro LF, Buso L, Ozcan M (2007) The influence of cervical finish line, internal relief, and cement type on the cervical adaptations of metal crowns. Quintessence Int 38(7):425–432

Fusayama T (1959) Factors and technique of precision casting part II. J Prosthet Dent 9(6):1037–1048

Juntavee N, Millstein PL (1992) Effect of surface roughness and cement space on crown retention. J Prosthet Dent 68:482–486

Lombardas P, Carbunaru A, Mcalrney ME, Toothaker RW (2000) Dimensional accuracy of castings produced with ring less and metal ring investment systems. J Prosthet Dent 84(1):27–31

Ushiwata O, Moraes JV, Bottino MA, Silva EG (2000) Marginal fit of nickel chromium copings before and after internal adjustments with duplicated stone dies and disclosing agent. J Prosthet Dent 83(6):634–643

Akova T, Ucar Y, Tukay A, Balkaya MC, Brantley WA (2008) Comparison of the bond strength of laser-sintered and cast base metal dental alloys to porcelain. Dent Mater 24:1400–1404

Hung SH, Hung KS, David Eick J, Chappell RP (1990) Marginal fit of porcelain fused to metal and two types of ceramic crowns. J Prosthet Dent 63:26–33

Acknowledgments

My sincere thanks to Professor Dr. Karthik Bhanushali, Imaginarium Dental Lab, MIDC, Andheri East, Mumbai, for helping me with 3 dimensional printing (3DP), Mr. Nirav Jain Director (Dental Ceramists India. Pvt. Ltd) Bandra West Mumbai, for providing Direct Metal Laser Sintering (DMLS) Machine. I would like to thank the Department of Mechanical Engineering, Anna University for helping me in measuring the values with the help of Video Measuring System (VMS2010F).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhaskaran, E., Azhagarasan, N.S., Miglani, S. et al. Comparative Evaluation of Marginal and Internal Gap of Co–Cr Copings Fabricated from Conventional Wax Pattern, 3D Printed Resin Pattern and DMLS Tech: An In Vitro Study. J Indian Prosthodont Soc 13, 189–195 (2013). https://doi.org/10.1007/s13191-013-0283-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13191-013-0283-5