Abstract

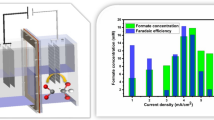

The Sn electrode possesses a high selectivity for formate production in electrochemical CO2 reduction. Understanding the relationship between the selectivity of formate and surface characteristics such as structure and chemical state is important for obtaining high activity. In this study, we fabricated a porous Sn electrode using a simple method of anodization in lactic acid. The anodized electrode had numerous 1-μm pores and its surface chemical state had a relatively high ratio of Sn0 compared with that of a bare Sn electrode. In the CO2 reduction reaction, the anodized Sn electrode showed a Faradaic efficiency (FE) of 35% for formate production at a low applied potential of −0.6 V vs. a reversible hydrogen electrode (RHE), with suppressed H2 generation. A Tafel analysis revealed that the slope of the anodized Sn electrode was 70 mV/decade, suggesting an increase in the stability of the CO2 radical anion. These results indicated that a coordinative unsaturation site such as the edge site formed by anodization contributes to a decrease in the overpotential and an increase in the reactive sites for formate production. Moreover, the surface structure appeared to be a significant factor in the production of formate at a very low applied potential relative to the surface oxidation state.

Textual abstract

The porous Sn electrode was prepared by anodization in lactic acid to increase the selectivity for formate at a low applied potential. Prepared porous Sn electrode enhances formate production from the CO2RR at a low applied potential due to the stabilization of the CO2 or its reaction intermediates.

Graphical Abstract

Similar content being viewed by others

References

E.A. Quadrelli, G. Centi, J.-L. Duplan, S. Perathoner, Carbon dioxide recycling: emerging large-scale technologies with industrial potential. Chemsuschem 4, 1194 (2011)

M. Peters, B. Köhler, W. Kuckshinrichs, W. Leitner, P. Markewitz, T.E. Müller, Chemical technologies for exploiting and recycling carbon dioxide into the value chain. Chemsuschem 4, 1216 (2011)

G.A. Olah, G.K.S. Prakash, A. Goeppert, Anthropogenic chemical carbon cycle for a sustainable future. J. Am. Chem. Soc. 133, 12881 (2011)

D.T. Whipple, P.J.A. Kenis, Prospects of CO2 utilization via direct heterogeneous electrochemical reduction. J. Phys. Chem. Lett. 1, 3451 (2010)

K.P. Kuhl, T. Hatsukade, E.R. Cave, D.N. Abram, J. Kibsgaard, T.F. Jaramillo, Electrocatalytic conversion of carbon dioxide to methane and methanol on transition metal surfaces. J. Am. Chem. Soc. 136, 14107 (2014)

J.T. Feaster, C. Shi, E.R. Cave, T. Hatsukade, D.N. Abram, K.P. Kuhl, C. Hahn, J.K. Nørskov, T.F. Jaramillo, Understanding selectivity for the electrochemical reduction of carbon dioxide to formic acid and carbon monoxide on metal electrodes. ACS Catal. 7, 4822 (2017)

F. Calle-Vallejo, M.T.M. Koper, A.S. Bandarenka, Tailoring the catalytic activity of electrodes with monolayer amounts of foreign metals. Chem. Soc. Rev. 42, 5210 (2013)

H. Noda, S. Ikeda, Y. Oda, K. Imai, M. Maeda, K. Ito, S. Ideka, Y. Oda, K. Imai, M. Maeda, I. Kaname, Electrochemical reduction of carbon dioxide at various metal electodes in aqueous potassium hydrogen carbonate solution. Bull. Chem. Soc. Jpn. 63, 2459 (1990)

C. Zhao, J. Wang, Electrochemical reduction of CO2 to formate in aqueous solution using electro-deposited Sn catalysts Chem. Eng. J. 293, 161 (2016)

A. Dutta, C.E. Morstein, M. Rahaman, A. Cedeno López, and P. Broekmann, Beyond copper in CO2 electrolysis: effective hydrocarbon production on silver-nanofoam catalysts. ACS Catal. 8, 8357 (2018)

Y.-C. Hsieh, S.D. Senanayake, Y. Zhang, W. Xu, D.E. Polyansky, Effect of chloride anions on the synthesis and enhanced catalytic activity of silver nanocoral electrodes for CO2 electroreduction. ACS Catal. 5, 5349 (2015)

M. Morimoto, Y. Takatsuji, K. Hirata, T. Fukuma, T. Ohno, T. Sakakura, T. Haruyama, Visualization of catalytic edge reactivity in electrochemical CO2 reduction on porous Zn electrode. Electrochim. Acta 290, 255 (2018)

Y. Peng, T. Wu, L. Sun, J.M.V. Nsanzimana, A.C. Fisher, X. Wang, Selective electrochemical reduction of CO2 to ethylene on nanopores-modified copper electrodes in aqueous solution. ACS Appl. Mater. Interfaces 9, 32782 (2017)

A. Dutta, M. Rahaman, M. Mohos, A. Zanetti, P. Broekmann, Electrochemical CO2 conversion using skeleton (sponge) type of Cu catalysts. ACS Catal. 7, 5431 (2017)

P. De Luna, R. Quintero-Bermudez, C.-T. Dinh, M.B. Ross, O.S. Bushuyev, P. Todorović, T. Regier, S.O. Kelley, P. Yang, E.H. Sargent, Catalyst electro-redeposition controls morphology and oxidation state for selective carbon dioxide reduction. Nat. Catal. 1, 103 (2018)

H.S. Jeon, S. Kunze, F. Scholten, and B. Roldan Cuenya, Prism-shaped Cu nanocatalysts for electrochemical CO2 reduction to ethylene. ACS Catal. 8, 531 (2018)

A. Dutta, M. Rahaman, N.C. Luedi, M. Mohos, P. Broekmann, Morphology matters: tuning the product distribution of CO2 electroreduction on oxide-derived Cu foam catalysts. ACS Catal. 6, 3804 (2016)

B. Qin, H. Wang, F. Peng, H. Yu, and Y. Cao, Effect of the surface roughness of copper substrate on three-dimensional tin electrode for electrochemical reduction of CO2 into HCOOH. J. CO2 Util. 21, 219 (2017)

D. Li, J. Wu, T. Liu, J. Liu, Z. Yan, L. Zhen, and Y. Feng, Tuning the pore structure of porous tin foam electrodes for enhanced electrochemical reduction of carbon dioxide to formate. Chem. Eng. J. 375, 122024 (2019)

Y. Hori, H. Wakebe, T. Tsukamoto, O. Koga, Electrocatalytic process of CO selectivity in electrochemical reduction of CO2 at metal electrodes in aqueous media. Electrochim. Acta 39, 1833 (1994)

J.S. Yoo, R. Christensen, T. Vegge, J.K. Nørskov, F. Studt, Theoretical insight into the trends that guide the electrochemical reduction of carbon dioxide to formic acid. Chemsuschem 9, 358 (2016)

Y. Chen, M.W. Kanan, Tin oxide dependence of the CO2 reduction efficiency on tin electrodes and enhanced activity for tin/tin oxide thin-film catalysts. J. Am. Chem. Soc. 134, 1986 (2012)

M.F. Baruch, J.E. Pander, J.L. White, A.B. Bocarsly, Mechanistic insights into the reduction of CO2 on tin electrodes using in situ ATR-IR spectroscopy. ACS Catal. 5, 3148 (2015)

X. An, S. Li, A. Yoshida, Z. Wang, X. Hao, A. Abudula, G. Guan, Electrodeposition of tin-based electrocatalysts with different surface tin species distributions for electrochemical reduction of CO2 to HCOOH. ACS Sustain. Chem. Eng. 7, 9360 (2019)

M. Morimoto, Y. Takatsuji, R. Yamasaki, H. Hashimoto, I. Nakata, T. Sakakura, T. Haruyama, Electrodeposited Cu-Sn alloy for electrochemical CO2 reduction to CO/HCOO−. Electrocatalysis 9, 323 (2018)

Y. Takatsuji, I. Nakata, M. Morimoto, T. Sakakura, R. Yamasaki, T. Haruyama, Highly selective methane production through electrochemical CO2 reduction by electrolytically plated Cu-Co electrode. Electrocatalysis 10, 29 (2019)

M. Morimoto, Y. Takatsuji, S. Iikubo, S. Kawano, T. Sakakura, T. Haruyama, Experimental and theoretical elucidation of electrochemical CO2 reduction on an electrodeposited Cu3Sn alloy. J. Phys. Chem. C 123, 3004 (2019)

S. Back, M.S. Yeom, and Y. Jung, Active sites of Au and Ag nanoparticle catalysts for CO2 electroreduction. to CO ACS Catal. 5, 5089 (2015)

T. Saberi Safaei, A. Mepham, X. Zheng, Y. Pang, C.T. Dinh, M. Liu, D. Sinton, S.O. Kelley, and E.H. Sargent, High-density nanosharp microstructures enable efficient CO2 electroreduction. Nano. Lett. 16, 7224 (2016)

T.T.H. Hoang, S. Ma, J.I. Gold, P.J.A. Kenis, A.A. Gewirth, Nanoporous copper films by additive-controlled electrodeposition: CO2 reduction catalysis. ACS Catal. 7, 3313 (2017)

Y. Chen, C.W. Li, M.W. Kanan, Aqueous CO2 reduction at very low overpotential on oxide-derived au nanoparticles. J. Am. Chem. Soc. 134, 19969 (2012)

D.H. Won, C.H. Choi, J. Chung, M.W. Chung, E.-H. Kim, S.I. Woo, Rational design of a hierarchical tin dendrite electrode for efficient electrochemical reduction of CO2. Chemsuschem 8, 3092 (2015)

L. Fan, Z. Xia, M. Xu, Y. Lu, Z. Li, 1D SnO2 with wire-in-tube architectures for highly selective electrochemical reduction of CO2 to C1 products. Adv. Funct. Mater. 28, 1706289 (2018)

S. Lee, J.D. Ocon, Y. Il Son, and J. Lee, Alkaline CO2 electrolysis toward selective and continuous HCOO- production over SnO2 nanocatalysts. J. Phys. Chem. C 119, 4884 (2015)

R. Daiyan, X. Lu, Y.H. Ng, R. Amal, Surface engineered tin foil for electrocatalytic reduction of carbon dioxide to formate. Catal. Sci. Technol. 7, 2542 (2017)

B.K. Körbahti and K.M. Turan, Evaluation of energy consumption in electrochemical oxidation of acid violet 7 textile dye using Pt/Ir electrodes. J. Turkish Chem. Soc. Sect. A Chem. 3, 75 (2016)

Funding

This work was partially supported by a Grant-in-Aid for Early-Career Scientist (Grant Number 18K14324).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Morimoto, M., Fujita, N., Takatsuji, Y. et al. Decreasing the Overpotential for Formate Production in Electrochemical CO2 Reduction Achieved by Anodized Sn Electrode. Electrocatalysis 13, 72–80 (2022). https://doi.org/10.1007/s12678-021-00695-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12678-021-00695-2