Abstract

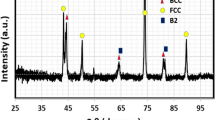

Microstructural and electrochemical corrosion behaviours of Al40(SiCrFeMnNiCu)60 (at %) high entropy alloy (HEA) were studied. The as-cast-alloy formed B2 and Cr5Si3 intermetallic phases. The HEA showed active, passive and transpassive behaviour for pH (0–3), and spontaneous passivity for pH (14–11). The HEA showed higher transpassive dissolution at low pH values than alkaline pH values. This has been attributed to minor variation in the passive film composition of the HEA between the acidic and alkaline pH condition as observed using X–ray photoelectron spectroscopy (XPS). Considering the beneficial role of copper and silicon in sulphuric acid in stabilizing the passive film in reducing the critical current density for passivation and also the role of silicon in stabilizing the passive film, they are suggested to be responsible for the improved passivity. In 3.5 wt% NaCl solution, the alloy did not show any kind of passivity. The selective dissolution of the alloy was evident at B2/Cr5Si3 interface regions and the Cr5Si3 phase showed relatively more resistance to corrosion.

Similar content being viewed by others

Data Availability

Data will be made available on reasonable request.

References

Tokarewicz M, and Grądzka-Dahlke M, Metals (Basel) 11 (2021) 1. https://doi.org/10.3390/met11081302

Gu X H, Huang Q Y, Chen J B, Hu H S, Sun Q Q, Wu L K, and Cao F H, J Alloys Compd 968 (2023) 1. https://doi.org/10.1016/j.jallcom.2023.172091

Shivam V, Basu J, Pandey V K, Shadangi Y, and Mukhopadhyay N K, Adv Powder Technol 29 (2018) 2221. https://doi.org/10.1016/j.apt.2018.06.006

Shivam V, Shadangi Y, Basu J, and Mukhopadhyay N K, J Alloys Compd. 832 (2020) 1. https://doi.org/10.1016/j.jallcom.2020.154826

Zhou P F, Xiao D H, and Yuan T C, Acta Metallurgica Sinica (English Letters). 33 (2020) 937. https://doi.org/10.1007/s40195-019-00962-8

Yang Y, Luo X, Ma T, Wen L, Hu L, and Hu M, J Alloys Compd. 864 (2021) 864. https://doi.org/10.1016/j.jallcom.2021.158717

Li M, Gazquez J, Borisevich A, Mishra R, and Flores K M, Intermetall (Barking) 95 (2018) 110. https://doi.org/10.1016/j.intermet.2018.01.021

Munitz A, Meshi L, and Kaufman M J, Mater Sci Eng A 689 (2017) 384. https://doi.org/10.1016/j.msea.2017.02.072

Masemola K, Popoola P, and Malatji N, J Mater Res Technol 9 (2020) 5241. https://doi.org/10.1016/j.jmrt.2020.03.050

Yang J, Wu J, Zhang C Y, Zhang S D, Yang B J, Emori W, and Wang J Q, J Alloy Compd 819 (2020) 1. https://doi.org/10.1016/j.jallcom.2019.152943

Zhu M, Li K, Liu Y, Wang Z, Yao L, Fa Y, and Jian Z, Trans Indian Instit Metals 73 (2020) 389. https://doi.org/10.1007/s12666-019-01850-6

Yang B, Hou Y, Lei Q, Li Y, and Chiba A, Mater Charact 161 (2020) 1. https://doi.org/10.1016/j.matchar.2020.110140

Wang J, Jiang H, Chang X, Zhang L, Wang H, Zhu L, and Qin S, Corros Sci 221 (2023) 1. https://doi.org/10.1016/j.corsci.2023.111313

Yu Y, Xu N, Zhu S, Qiao Z, Zhang J, Yang J, and Liu W, J Mater Sci Technol 69 (2021) 48. https://doi.org/10.1016/j.jmst.2020.08.016

Xiang C, Zhang Z M, Fu H M, Han E H, Zhang H F, and Wang J Q, Intermetallics (Barking) 114 (2019) 1. https://doi.org/10.1016/j.intermet.2019.106599

Pratskova S, Samoilova O, Ageenko E, Shaburova N, Moghaddam A O, and Trofimov E, Metals (Basel) 12 (2022) 1. https://doi.org/10.3390/met12020352

Yang Y, Ren Y, Tian Y, Li K, Zhang W, Shan Q, Tian Y, Huang Q, and Wu H, J Alloys Compd 884 (2021) 1. https://doi.org/10.1016/j.jallcom.2021.161070

Abdelfatah A, Raslan A M, and Mohamed L Z, Int J Electrochem Sci 17 (2022) 1. https://doi.org/10.20964/2022.04.29

Arellanes-Lozada P, Olivares-Xometl O, Guzmán-Lucero D, Likhanova N V, Domínguez-Aguilar I, Lijanova V, and Arce-Estrada E, Materials 7 (2014) 5711. https://doi.org/10.3390/ma7085711

Łoński W, Spilka M, Kądziołka-Gaweł M, Gębara P, Radoń A, Warski T, Łoński S, Barbusiński K, Młynarek-Żak K, and Babilas R, J Alloys Compd 934 (2023) 1. https://doi.org/10.1016/j.jallcom.2022.167827

Kumar N, Fusco M, Komarasamy M, Mishra R S, Bourham M, and Murty K L, J Nuclear Mater 495 (2017) 154. https://doi.org/10.1016/j.jnucmat.2017.08.015

Godlewska E M, Mitoraj-Królikowska M, Czerski J, Jawańska M, Gein S, and Hecht U, Front Mater 7 (2020) 1. https://doi.org/10.3389/fmats.2020.566336

Guo W, Li J, Qi M, Xu Y, and Ezatpour H R, Intermetall (Barking) 138 (2021) 1. https://doi.org/10.1016/j.intermet.2021.107324

Islam M S, and Sakairi M, Corrosion Commun 5 (2022) 39. https://doi.org/10.1016/j.corcom.2022.01.001

Chen D, Howe K J, Dallman J, and Letellier B C, Corros Sci 50 (2008) 1046. https://doi.org/10.1016/j.corsci.2007.11.034

Chen C, Zhang H, Fan Y, Wei R, Zhang W, Wang T, Zhang T, Wu K, Li F, Guan S, and Jiang J, Intermetall (Barking) 122 (2020) 1. https://doi.org/10.1016/j.intermet.2020.106778

Sohn M, Il P H, and Kim H, Chem Commun 53 (2017) 11897. https://doi.org/10.1039/c7cc06171d

Lee C P, Chen Y Y, Hsu C Y, Yeh J W, and Shih H C, Thin Solid Films 517 (2008) 1301. https://doi.org/10.1016/j.tsf.2008.06.014

Keller P, and Strehblow H H, Corros Sci 2004 (1939) 46. https://doi.org/10.1016/j.corsci.2004.01.007

Wang J, Zhang Z, Dai H, Fujiwara H, Chen X, and Ameyama K, Corros Sci 209 (2022) 1. https://doi.org/10.1016/j.corsci.2022.110761

Cui Z, Wang L, Ni H, Hao W, Man C, Chen S, Wang X, Liu Z, and Li X, Corros Sci 118 (2017) 31. https://doi.org/10.1016/j.corsci.2022.110761

Lai W Y, Zhao W Z, Yin Z F, and Zhang J, Surface Interface Anal 44 (2012) 418. https://doi.org/10.1016/j.corsci.2017.01.016

Tan C W, Daud A R, and Yarmo M A, Appl Surf Sci 19 (2002) 67. https://doi.org/10.1016/S0169-4332(02)00150-2

Author information

Authors and Affiliations

Contributions

Ritik Roshan Tripathy: Conceptualization, Data curation, Investigation, Formal analysis, Methodology, Writing—Original draft, Yagnesh Shadangi: Alloy development, Formal analysis, Investigation, Methodology, Writing—Review and Editing. Priyatosh Pradhan: Methodology, Data curation. Bratindranath Mukherjee: Conceptualization, Resources, Supervision, Writing—Review and Editing; V.S. Raja: Discussion, Formal analysis, Writing-Review and Editing. Nilay Krishna Mukhopadhyay: Supervision, Conceptualization, Formal analysis, Writing-Review and Editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tripathy, R.R., Shadangi, Y., Pradhan, P. et al. Effect of Copper and Silicon on the Corrosion Properties of the AlCrFeMnNi High Entropy Alloy. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-024-03325-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-024-03325-9