Abstract

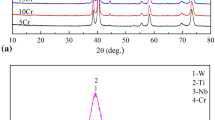

This study focuses on synthesizing and characterizing mechanically alloyed refractory high entropy alloys (RHEA) containing TiMoNb, Cr, W, and Cr + W. Analytical techniques including XRD, SEM, EDX, DTA, and TGA were employed to explore the influence of Cr and W on the alloys' structure, morphology, and thermal stability towards oxidation. XRD analysis confirmed the formation of a single-phase bcc solid solution in TiMoNbCr, TiMoNbW, and TiMoNbCrW alloys. Crystallite size decreased as milling progressed, yielding average sizes of approximately 7.2 nm, 7.4 nm, and 9.7 nm, with lattice strains of 1.143%, 1.148%, and 1.15%, respectively. Both experimental and calculated values of lattice parameters converged to around 3.1685 ± 0.002 and 3.1791 ± 0.010 Å for all three alloys. The synergy of Cr and W in TiMoNb was observed for the first time, impacting dislocation density, hardness, and oxidation stability. TiMoNbCrW exhibited reduced dislocation density and the highest hardness (502 HV). TGA indicated enhanced oxidation resistance up to 400 °C for TiMoNbCrW compared to the most vulnerable TiMoNbCr alloy.

Similar content being viewed by others

References

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, and Chang S Y, Adv Mater Sci 6 (2004) 299. https://doi.org/10.1002/adem.200300567.

Shi Y, Yang B, Xie X, Brechtl J, Dahmen K A, and Liaw P K, Corros Sci 119 (2017) 33. https://doi.org/10.1016/j.corsci.2017.02.019.

Murthy B S, Yeh J W, Ranganathan S, and Bhattacharjee P P, High-Entropy Alloys, 2nd edn, Elsevier (2019, 2020) p 388, Paperback ISBN: 9780128160671.

Zhu C, Li Z, Hong C, Dai P, and Chen J, Int J Refract Met Hard Mater 93 (2020) 105357. https://doi.org/10.1016/j.ijrmhm.2020.105357.

Miracle D B, and Senkov O N, Acta Mater 122 (2017) 448. https://doi.org/10.1016/j.actamat.2016.08.081.

Zhao Y J, Qiao J W, Ma S G, Gao M C, Yang H J, Chen M W, and Zhang Y, Mater Des 96 (2016) 10. https://doi.org/10.1016/j.matdes.2016.01.149.

Poulia A, Georgatis E, Lekatou A, and Karantzalis A E, Int J Refract Met Hard Mater 57 (2016) 50. https://doi.org/10.1016/j.ijrmhm.2016.02.006.

Zhang Y, Zuo T T, Tang Z, Gao M C, Dahmen K A, Liaw P K, and Lu Z P, Prog Mater 61 (2014) 1. https://doi.org/10.1016/j.pmatsci.2013.10.001.

Tian Y Z, Sun S J, Lin H R, and Zhang Z F, Mater Sci 35 (2019) 334. https://doi.org/10.1016/j.jmst.2018.09.068.

Ye Y F, Wang Q, Lu J, Liu C T, and Yang Y, Mater Today 19 (2016) 349. https://doi.org/10.1016/j.mattod.2015.11.026.

Tsai M-H, and Yeh J-W, Mater Res Lett 2 (2014) 107. https://doi.org/10.1080/21663831.2014.912690.

Senkov O N, Wilks G B, Scott J M, and Miracle D B, Intermet 19 (2011) 698. https://doi.org/10.1016/j.intermet.2011.01.004.

Senkov O N, Wilks G B, Miracle D B, Chuang C P, and Liaw P K, Intermet 18 (2010) 1758. https://doi.org/10.1016/j.intermet.2010.05.014.

Han Z D, Chen N, Zhao S F, Fan L W, Yang G N, Shao Y, and Yao K F, Intermet 84 (2017) 153. https://doi.org/10.1016/j.intermet.2017.01.007.

Couzinié J P, Dirras G, Perriére L, Chauveau T, Leroy E, Champion Y, and Guillot I, Mater Lett 126 (2014) 285. https://doi.org/10.1016/j.matlet.2014.04.062.

Senkov O N, Senkova S V, and Woodward C, Acta Mater 68 (2014) 214. https://doi.org/10.1016/j.actamat.2014.01.029.

Zhao S F, Yang G N, Ding H Y, and Yao K F, Intermet 61 (2015) 47. https://doi.org/10.1016/j.intermet.2015.02.011.

Yao H W, Qiao J W, Gao M C, Hawk J A, Ma S G, Zhou H F, and Zhang Y, Mater Sci Eng A 674 (2016) 203. https://doi.org/10.1016/j.msea.2016.07.102.

Senkov O N, Scott J M, Senkova S V, Miracle D B, and Woodward C F, J Alloy Compd 509 (2011) 6043. https://doi.org/10.1016/j.jallcom.2011.02.171.

Wang S-P, and Xu J, Mater Sci Eng 73 (2017) 80. https://doi.org/10.1016/j.msec.2016.12.057.

Yurchenko N Y, Stepanov N D, Zherebtsov S V, Tikhonovsky M A, and Salischchev G A, Mater Sci Eng 704 (2017) 82. https://doi.org/10.1016/j.msea.2017.08.019.

Senkov O N, Senkova S V, Miracle D B, and Woodward C, Mater Sci Eng 565 (2013) 51. https://doi.org/10.1016/j.actamat.2012.11.032.

Senkov O N, and Woodward C F, Mater Sci Eng 529 (2011) 311. https://doi.org/10.1016/j.msea.2011.09.033.

Long Y, Liang X, Su K, Peng H, and Li X, J Alloy Compd 780 (2019) 607. https://doi.org/10.1016/j.jallcom.2018.11.318.

Takeuchi A, and Inoue A, Mater Trans 46 (2005) 2817. https://doi.org/10.2320/matertrans.46.2817.

Liu L, Liu H, Zhang X, Wang Y, and Hao X, Materials 16 (2023) 3860. https://doi.org/10.3390/ma16103860.

Das S, and Robi P S, Int J Refract Metals Hard Mater 100 (2021) 105656. https://doi.org/10.1016/j.ijrmhm.2021.105656.

Williamson G K, and Hall W H, Acta Metall 1 (1953) 22. https://doi.org/10.1016/0001-6160(53)90006-6.

Rasband W, Natl Inst Health USA 8 (2014), https://doi.org/10.4236/ajps.2017.87117.

Suryanarayana C, Prog Mater Sci 46 (2001) 1, in English.

Shivam V, Basu J, Pandey V K, Shadangi Y, and Mukhopadhyay N K, Adv Powder Technol 29 (2018) 2221. https://doi.org/10.1016/j.apt.2018.06.006.

Avar B, Chattopadhyay A K, Simsek T, Simsek T, Ozcan S, and Kalkan B, Appl Phys 128 (2022) 537.

Guo J, Tang C, and Lai H S, Mater 15 (2022) 1444. https://doi.org/10.3390/ma15041444.

Javdan M, Gheisari Kh, and Reihanian M, J Alloy Compd 952 (2023) 170030. https://doi.org/10.1016/j.jallcom.2023.170030, in English.

Jahani N, Reihanian M, and Gheisari K, Mater Sci Technol (2023), in English. https://doi.org/10.1080/02670836.2023.2180902.

Zhang Y, Zhou Y J, Lin J P, Chen G L, and Liaw P K, Adv Eng Mater 10 (2008) 534. https://doi.org/10.1002/adem.200700240.

Yang X, and Zhang Y, Mater Chem Phys 2 (2012) 132. https://doi.org/10.1016/j.matchemphys.2011.11.021.

Wang Z, Li H J, Zhang L L, and Pu Y P, Mater Res Bull 53 (2014) 28. https://doi.org/10.1016/j.materresbull.2014.01.025.

Guo S, Ng C, Lu J, and Liu C T, J App Phys 109 (2011) 103505. https://doi.org/10.1063/1.3587228.

Shivam V, Sanjana V, and Mukhopadhyay N K, Trans Indian Inst Met 73 (2020) 821. https://doi.org/10.1007/s12666-020-01892-1.

Shivam V, Basu J, Shadangi Y, Singh M K, and Mukhopadhyay N K, J Alloy Compd 757 (2018) 87. https://doi.org/10.1016/j.jallcom.2018.05.057.

Singh N, Shadangi Y, Goud G S, Pandey V K, Shivam V, and Mukhopadhyay N K, Trans Indian Inst Met 74 (2021) 2203. https://doi.org/10.1007/s12666-021-02262-1.

Hull D, and Bacon D J, Introduction to Dislocations, 5th edn, Elsevier, Oxford (2011), Paperback ISBN: 9780080966724.

Davis R, Metall 8 (1978) 41. https://doi.org/10.1007/BF02881476.

Moffat D, and Kattner U, Metall (1988) 2389, https://doi.org/10.1007/BF02645466.

Bönisch M, Calin M, Waitz T, Panigrahi A, Zehetbauer M, Gebert A, Skrotzki W, and Eckert J, Sci Tech Adv Mater 14 (2013), https://doi.org/10.1088/1468-6996/14/5/055004.

Author information

Authors and Affiliations

Contributions

TS: performed the experiments, data analysis, writing the first and final draft of manuscript, editing, reviewing, supervision, MAK: performed the experiments, data analysis, BA: writing the first draft of manuscript, data analysis, editing, reviewing, SHG: performed the experiments and characterizations of the thermal analysis, İD: hardness analysis were achieved, AKC: reviewing, data analysis, editing, writing the final draft of manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Simsek, T., Kurtulus, A., Avar, B. et al. Effects of Cr and W in TiMoNb Refractory High Entropy Alloys. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-023-03259-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-023-03259-8