Abstract

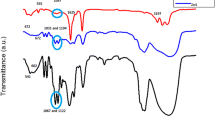

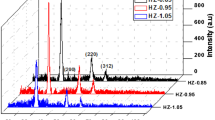

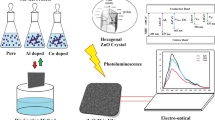

Cu-doped ZnO nanofilms were prepared by sol–gel process using zinc acetate dihydrate, Copper (II) chloride dihydrate as a precursor and ethanol as solvent. The influence of Cu-doping concentration (2 wt%, 5 wt% and 7 wt%) and withdrawal speed of the dip coating process (20, 50 and 100 mm/min) on the structural, morphological and optical properties of the nanofilms have been investigated. The prepared films were characterized by x-ray diffraction (XRD), atomic force microscopy, scanning electron microscope (SEM), energy dispersive x-ray spectroscopy (EDS), and UV–visible. The XRD patterns show the typical hexagonal ZnO in the (002) plane, and the crystallite size of the doped film increases with the doping concentration and withdrawal speed. The SEM images show that the morphological surface of the films was affected by Cu doping. The successful doping of ZnO films with Cu was confirmed by the EDS analysis. The transmittance considerably decreases accompanying increase in the Cu concentration, and increases as the withdrawal speed increases from 20 to 100 mm/min. The optical band gap of pure and Cu-doped ZnO was found to decrease from 3.25 to 3.18 eV as the withdrawal speed increased.

Similar content being viewed by others

References

Chen Y, IOP Conf Ser Mater Sci Eng 423 (2018) 012170. https://doi.org/10.1088/1757-899X/423/1/012170

Fang Z, Tian S, Li B, Liu Q, Liu B, Zhao X, and Sankar G, Appl Surf Sci 540 (2021) 148414. https://doi.org/10.1016/j.apsusc.2020.148414

Islam B, Sadiq M, Arif M, Haider F, and Ahmad N, Trans Indian Inst Met (2023). https://doi.org/10.1007/s12666-023-02989-z

Boruah B D, Nanoscale Adv 1 (2019) 2059. https://doi.org/10.1039/c9na00130arsc.li/nanoscale-advances

Galstyann V, Comini E, Baratto C, Faglia G, and Sberveglieri G, Ceram Int 41B (2015) 14239. https://doi.org/10.1016/j.ceramint.2015.07.052

Zhao C Y, Liu Z R, Sun B, Tang J, Xu P S, Xie J C, and Phys E, Low-Dimensional Syst Nanostruct 41 (2009) 479. https://doi.org/10.1016/j.physe.2008.09.021

Kathalingam A, and Kim H S, Opt Mater Express 8 (2018) 2832. https://doi.org/10.1364/OME.8.002832

Valenzuela L, Faraldos M, Bahamonde A, and Rosal R, Curr Opin Chem Eng 34 (2021) 100762. https://doi.org/10.1016/j.coche.2021.100762

Licurgo J S C, De Almeida Neto G R, and Paes Junior H R, Cerâmica 66 (2020) 284. https://doi.org/10.1590/0366-69132020663792877

Thakur S, Sharma N, Varkia A, and Kumar J, Adv Appl Sci Res 5 (2014) 18.

Chauhan J, Shrivastav N, Dugaya A, and Pandey D, J Nanomed Nanotechnol 1 (2017) 26. https://doi.org/10.4172/2157-7439.1000429

Chen G J, Jian S R, and Juang J Y, Coatings 8 (2018) 266. https://doi.org/10.3390/coatings8080266

Tyona M D, Creat Commons Attrib License (2019). https://doi.org/10.5772/intechopen.86254

Mhamdi A, Mimouni R, Amlouk A, Amlouk M, and Belgacem S, J Alloys Compd 610 (2014) 250. https://doi.org/10.1016/j.jallcom.2014.04.007

Ray R, Kumar A, Paul A K, and Tyagi S, Trans Indian Inst Met 69 (2016) 1043. https://doi.org/10.1007/s12666-015-0618-5

Lee J B, Le H J, Seo S H, and Park J S, Thin Solid Films 398 (2001) 641. https://doi.org/10.1016/S0040-6090(01)01332-3

Pung S Y, Ong C S, Mohd Isha K, and Othman M H, Sains Malays 43 (2014) 273.

Bhubesh C J, and Chaudhri A K, ACS Omega 7 (2022) 21877. https://doi.org/10.1021/acsomega.2c02040

Gupta V, and Mansingh A, J Appl Phys 80 (1996) 1063. https://doi.org/10.1063/1.362842

Mathew J P, Varghese G, and Mathew J, SOP Trans Nano-technol 1 (2014) 1. https://doi.org/10.15764/NANO.2014.03001

Langford J I, and Wilson A J C, J Appl Cryst 11 (1978) 102. https://doi.org/10.1107/S0021889878012844

Srinivasulu T, Saritha K, and Reddy K T R, MoEM 3 (2017) 76. https://doi.org/10.1016/j.moem.2017.07.001

Tsai C Y, Lai J D, Feng S W, Chen C H, and Tu L W, Superlattices Microstruct 111 (2017) 1073. https://doi.org/10.1016/j.spmi.2017.08.015

Sharma P K, Dutta R K, and Pandey A C, J Magn Magn Mater 321 (2009) 4001. https://doi.org/10.1016/j.jmmm.2009.07.066

Devi K R, Selvan G, Karunakaran M, Raj I L P, Ganesh V, and AlFaify S, Mater Sci Semicond Process 119 (2020) 105117. https://doi.org/10.1016/j.mssp.2020.105117

Masashi O, Hiromitsu K, and Toshinobu Y, Thin Solid Films 306 (1997) 78. https://doi.org/10.1016/S0040-6090(97)00231-9

Touam T, Atoui M, Hadjoub I, Chelouche A, Boudine B, Fischer A, Boudrioua A, and Doghmane A, Eur Phys J Appl Phys 67 (2014) 30302. https://doi.org/10.1051/epjap/2014140228

Kaneva N V, and Dushkin C D, Bulg Chem Commus 43 (2011) 259.

Zegadi C, Abdelkebir K, Chaumont D, Adnane M, and Hamzaoui S, AMPC 4 (2014) 93.

Tsay C Y, Cheng H C, Tung Y T, Tuan W H, and Lin C K, Thin Solid Films 517 (2008) 1032. https://doi.org/10.1016/j.tsf.2008.06.030

Tneh S S, Hassan Z, Saw K G, Yam F K, and Hassan A H, Physica B 405 (2010) 2045. https://doi.org/10.1016/j.physb.2010.01.099

Sreedhar A, Kwon J H, Yi J, Kim J S, and Gwag J S, Mater Sci Semicond Process 49 (2016) 8. https://doi.org/10.1016/j.mssp.2016.03.023

Klein LC, Sol–Gel Technology for Thin Films, Fibers, Preforms, Electronics, and Specialty Shapes, Noyes Publications (1988) https://doi.org/10.1002/adma.19890010816

Sinem A, Vacuum 120 (2015) 51. https://doi.org/10.1016/j.vacuum.2015.05.041

Rio E, and Boulogne F, Adv Colloid Interface Sci 247 (2017) 100. https://doi.org/10.1016/j.cis.2017.01.006

Burstein E, Phys Rev 93 (1954) 632. https://doi.org/10.1103/PhysRev.93.632

Moss T S, Proc Phys Soc B 67 (1954) 775. https://doi.org/10.1088/0370-1301/67/10/306

Acknowledgements

This work was carried out in Active Components and Materials Laboratory, University of Oum El Bouaghi, Algeria. The authors are grateful to Director of the laboratory of materials and structure of electromechanical systems and their reliability (LMSSEF) of Oum El Bouaghi University, Algeria, for X-ray diffraction analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Salima, B., Seddik, B., Nassima, S. et al. Investigation of the Doping and Withdrawal Speed Effect on the Properties of sol–gel Dip-coated Cu-Doped ZnO Thin Films. Trans Indian Inst Met 77, 1195–1203 (2024). https://doi.org/10.1007/s12666-023-03242-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03242-3