Abstract

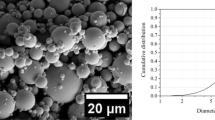

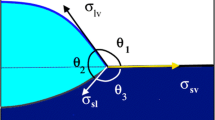

The paper presents a method for the synthesis of metal pastes and diffusion-hardening alloys based on gallium by intensive vibrational mixing of powder components: solid gallium and a complex of filler powders. Using this method (with a specially selected fractional composition of powdered components), a series of samples of Cu–Ga–Sn alloys were obtained—one of the “classic” systems used (with various additives) as metal solder adhesives and dental filling materials. Structural, thermochemical (DSC), physical and mechanical properties, phase composition of initial and hardened samples are presented. When mixing, dosing and storing the components of the initial powder mixture, there is no noticeable segregation, contact-reactive melting of the components. The production of gallium pastes in this work includes the synthesis of the liquid metal component in situ, in the process of vibration treatment of the powder mixture. In addition to ease of use, this method, apparently, can provide new opportunities for the design of the structure of gallium pastes, putties, hard metal solder adhesives and filling materials.

Graphical Abstract

Similar content being viewed by others

Data Availability

Data are contained within the article.

References

Tang S-Y, Tabor C, Kalantar-Zadeh K, and Dickey M D, Annu Rev Mater Res 51 (2021) 381. https://doi.org/10.1146/annurev-matsci-080819-125403

Ding Y, Zeng M, and Fu L, Matter 3 (2020) 1477. https://doi.org/10.1016/j.matt.2020.08.012

Pathumudy R D, and Prabhu K N, J Mater Sci Mater Electron 32 (2021) 11339. https://doi.org/10.1007/s10854-021-05635-w

Ozutemiz K B, Wissman J, Ozdoganlar O B, and Majidi C, Adv Mater Interfaces 5 (10), (2018) 1701596(1–13). https://doi.org/10.1002/admi.201701596

Khondoker M A H, and Sameoto D, Smart Mater Struct 25 (2016) 093001(1–23). https://doi.org/10.1088/0964-1726/25/9/093001

Guymon G G, and Malakooti M H, J Polym Sci 60 (2022) 1300. https://doi.org/10.1002/pol.20210867

Sun W, Qi M, Cheng S, Li C, Dong B, and Wang L, Mater Des 227 (2023) 111704(1–21). https://doi.org/10.1016/j.matdes.2023.111704

Xie W, Allioux F-M, Ou J Z, Miyako E, Tang S-Y, and Kalantar-Zadeh K, Trends Biotechnol 39 (6), (2021) 624. https://doi.org/10.1016/j.tibtech.2020.10.005

Liu S, and Sweatman K, Materials 11 (2018) 1384. https://doi.org/10.3390/ma11081384

Grigoreva T F, Kovaleva S A, Barinova A P, Šepelák V, Vityaz P A, and Lyakhov N Z, Phys Met Metallogr 111 (3), (2011) 258. https://doi.org/10.1134/S0031918X11020086

Smith D L, Caul H L, and Sweeney W T, J Am Dental Assoc 53 (1956) 677. https://doi.org/10.14219/jada.archive.1956.0250

Harman G G, Rev Sci Instrum 31 (7), (1960) 717. https://doi.org/10.1063/1.1717029

Tikhomirova O I, Pikunov M V, Ruzinov L P, and Marchukova I D, Mater Sci 5 (1972) 586. https://doi.org/10.1007/BF00721171

Yatsenko S P, and Hayak V G, Composition Solders Based on Fusible Alloys. Handbook, Urals Branch of RAS, Ekaterinburg (1997), p 187.

Yatsenko S P, Gallium: Interaction with Metals. Handbook, Nauka, Moscow (1974), p 220.

Hero H, Simensen C J, and Jorgensen R B, Biomaterials 17 (1996) 1321. https://doi.org/10.1016/S0142-9612(96)80009-3

Kaga M, Nakajima H, Sakai T, and Oguchi H, J Am Dental Assoc 127 (1996) 1195. https://doi.org/10.14219/jada.archive.1996.0411

Rybakov A I, Ivanov V S, and Karalnik D M, Dental-Filling Materials, Medicine, Moscow (1981), p 176.

Shaini F J, Fleming G J P, Shortall A C C, and Marquis P M, Dental Mater 17 (2001) 142. https://doi.org/10.1016/S0109-5641(00)00054-3

Waterstrat R M, and Longton R W, Public Health Rep 79 (7), (1964) 638. https://doi.org/10.2307/4592209

Pinasco M R, Angelini E, Cordano E, and Rosalbino F, J Alloys Compd 317–318 (2001) 411. https://doi.org/10.1016/S0925-8388(00)01418-3

Khudhair O A, Anaee R A, and Shabeeb K M, J Bio Tribo-Corros 6 (2020) 18(1–6). https://doi.org/10.1007/s40735-019-0313-x

Wang C, Gong Y, Cunning B V, Lee S, Le Q, Joshi S R, Buyukcakir O, Zhang H, Seong W K, Huang M, Wang M, Lee J, Kim G-H, and Ruoff R S, Sci Adv 7 (2021) eabe3767 (1-10). https://doi.org/10.1126/sciadv.abe3767

Shubin A B, Shunyaev K Y, and Yamshchikov L F, Defect Diffus Forum 283–286 (2009) 238. https://doi.org/10.4028/www.scientific.net/DDF.283-286.238

Shubin A B, Shunyaev K Y, Bykov V A, and Noritsin S I, Defect Diffus Forum 312–315 (2011) 301. https://doi.org/10.4028/www.scientific.net/DDF.312-315.301

Shemyakina O A, Sheikhalieva Z I, and Sheikhaliev S M, Russ J NonFerrous Met 51 (3), (2010) 250. https://doi.org/10.3103/S1067821210030107

Shubin A B, Yamshchikov L F, Raspopin S P, Method for manufacturing metal pastes containing gallium. Author's certificate of the USSR (Patent) No. 1696549. Published 12/07/1991. Bulletin No. 45

Shaker R E, Brantley W A, Wu Q, and Culbertson B M, Thermochim Acta 367–368 (2001) 393. https://doi.org/10.1016/S0040-6031(00)00660-2

Liu S, McDonald S, Gu Q, Matsumura S, Qu D, Sweatman K, Nishimura T, and Nogita K, J Electron Mater 49 (1), (2020) 128. https://doi.org/10.1007/s11664-019-07688-4

Lin Y, Genzer J, and Dickey M D, Adv Sci 7 (2020) 2000192(1–18). https://doi.org/10.1002/advs.202000192

Akyildiz K, Kim J-H, So J-H, and Koo H-J, J Ind Eng Chem 116 (2022) 120. https://doi.org/10.1016/j.jiec.2022.09.046

Kwon K Y, Truong V K, Krisnadi F, Im S, Ma J, Mehrabian N, Kim T, and Dickey M D, Adv Intell Syst 3 (2021) 2000159(1–11). https://doi.org/10.1002/aisy.202000159

Regan M J, Tostmann H, and Pershan P S, Phys Rev B 55 (16), (1997) 10786. https://doi.org/10.1103/PhysRevB.55.10786

Jacob A R, Parekh D P, Dickey M D, and Hsiao L C, Langmuir 35–36 (2019) 11774. https://doi.org/10.1021/acs.langmuir.9b01821

Saedi M, Mohseni S M, and Groot I M N, Mater Chem Phys 275 (2022) 125203.

Funding

The work was carried out according to the state assignment for IMET UB RAS, using equipment of the Collaborative usage center «Ural-M».

Author information

Authors and Affiliations

Contributions

AS contributed to conceptualization, methodology, writing—original draft preparation and resources; AS and IG contributed to writing—review and editing, synthesis and investigations and theoretical analysis; and IG contributed to project administration. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Informed Consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shubin, A., Gilev, I. Gallium-Based Metallic Pastes: Preparation from Powder Mixture by In Situ Synthesis of Liquid Component. Trans Indian Inst Met 77, 1063–1070 (2024). https://doi.org/10.1007/s12666-023-03235-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03235-2