Abstract

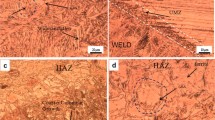

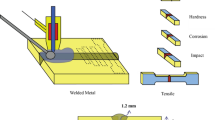

Incoloy 800HT and P91 steel were welded with two different filler materials (ERNiCr-3 and ER505) by the GTAW process. The microstructure of the two different weldments was examined by using optical microscope (OM) and scanning electron microscope (SEM). The corrosion behaviors of the base metals and welded joints were assessed by electrochemical corrosion studies. Microstructural analysis revealed that ERNiCr-3 filler-based weld showed equiaxed grains with columnar dendritic structure, whereas the ER505 filler-based weld had a mixed cellular and dendritic structure. An unmixed zone was found between the interface and the weld on the Incoloy 800HT side, whereas Type I and Type II boundaries were found on the P91 steel side. Due to the formation of chromium-rich M23C6 precipitates, a chromium-depleted zone was created near the grain boundary that deteriorated the corrosion resistance of the ER505 weld. Meanwhile, the ERNiCr-3 weld exhibited higher corrosion resistance due to the significant inclusion of Ni and Cr components.

Similar content being viewed by others

References

Ali M, Ul-Hamid A, Alhems L M, and Saeed A, Eng Fail Anal 109 (2020) 104396. https://doi.org/10.1016/j.engfailanal.2020.104396

Ming H, Wang J, and Han E H, Mater Charact 139 (2018) 186–196. https://doi.org/10.1016/j.matchar.2018.02.044

Tumer M, Karahan T, and Mert T, Weld World 64 (2020) 21. https://doi.org/10.1007/s40194-019-00825x

Hejripour F, and Aidun D K J, Mater Proc Technol 245 (2017) 287. https://doi.org/10.1016/j.jmatprotec.2017.02.013

Sayiram G, and Arivazhagan N, Mater Charact 102 (2015) 180.

Xu H, Xu M J, Yu C, Lu H, Wei X, Chen J M, and Xu J J, J Mater Process Technol 240 (2017) 162–167.

Rahman M A, Raheem N A, El Koussy M R, Acta Metallurgica Sinica (English Letters) 27 259

Abe H, and Watanabe Y, J Nuclear Mater 424 (2012) 57.

Zhang Z, Zhao H, Zhang H, Hu J, and Jin J, Corros Sci 121 (2017) 31.

Abbasi H, and Derakhshandeh-Haghighi R, Int J Pressure Vessels Piping 199 (2022) 104760

Lakshmanan V, and Sathiya P, Trans Indian Inst Met 72 (2019) 2673.

Bhanu V, Pandey S M, Gupta A, and Pandey C, Int J Pressure Vessels Piping 199 (2022) 104782

Sireesha M, Albert S K, Shankar V, and Sundaresan S, Mate Sci Eng A 292 (2000) 74.

Dehmolaei R, Shamanian M, and Kermanpur A, Mater Charact 59 (2008) 1447.

Panday C, Giri A, and Mahapatra M M, Mate Sci Eng A 664 (2016) 58.

Mortezaie A, and Shamanian M, Int J Press Vessel 116 (2014) 37.

Hosseini H S, Shamanian M, and Kermanpur A, Mater Charact 62 (2011) 425.

Dehmolaei R, Shamanian M, and Kermanpur A, Sci Technol Weld Join 13 (2008) 515.

Lee H T, and Jeng S L, Sci Technol Weld Join 6 (2001) 225. https://doi.org/10.1179/136217101101538811

Jiang Y, Tan H, and Wang Z, Corros Sci 70 (2013) 252.

Wang S, Ma Q, and Li Y, Mater Design 32 (2011) 831.

Wang W, Lu Y, Ding X, and Shoji T, Mater Charact 107 (2015) 255.

Kaneko K, Fukunaga T, Yamada K, Nakada N, Kikuchi M, Saghi Z, Barnard J S, and Midgley P A, Scripta Materialia 65 (2011) 509.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lakshmanan, V., Sathiya, P., Arunnellaiappan, T. et al. Correlation Between Microstructure and Corrosion Behavior of the Dissimilar Joints of Incoloy 800HT and P91 Steel Using GTAW Process. Trans Indian Inst Met 77, 685–696 (2024). https://doi.org/10.1007/s12666-023-03156-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03156-0