Abstract

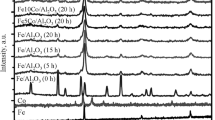

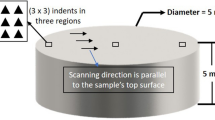

Nanostructured aluminum–titanium (Al–Ti) alloys are gaining interest for their unique properties resulting from the size effect of their crystalline structure. In this study, we synthesized Al–Ti alloys using a ball planetary mill with powdered Al and Ti components. The formation of the Al (Ti) solid solution was observed after 24 h of milling, and a crystalline size of 4 nm was attained after 48 h of milling. To investigate the electromagnetic behavior of the Al–Ti alloys during the milling process, we utilized eddy current analysis, which enabled us to monitor the nanostructural state of the material by analyzing its impedance diagram. Our results demonstrate that the eddy current method is an effective approach to assess the electromagnetic properties of nanostructured Al–Ti alloys. Furthermore, we conducted morphological and structural investigations of the synthesized alloys using scanning electron microscopy and X-ray diffractometer, respectively. In addition, we measured the mechanical properties of the alloys using micro-hardness tests and found that the impedance and microhardness varied in a similar manner. Based on these observations, we propose that the variation of microhardness can be estimated from the changes in impedance measured by the eddy current technique, providing a novel way to assess the mechanical properties of nanostructured Al–Ti alloys. This study highlights the successful synthesis and characterization of nanostructured Al–Ti alloys using a ball planetary mill. Our findings indicate the effectiveness of eddy current analysis in assessing the electromagnetic properties of these alloys and suggest a new approach to evaluate their mechanical properties. These results provide useful insights for designing and developing novel nanostructured Al–Ti alloys with customized properties for various applications.

Similar content being viewed by others

References

Koch Carl C, Nanostructured Materials: Processing, Properties and Applications, William Andrew, Norwich (2006).

Kumar A, Singh A, and Suhane A, J Mater Res Technol 17 (2022) 2431. https://doi.org/10.1016/j.jmrt.2022.01.141

Cocco G, Soletta I, Battezzati L, Baricco M, and Enzo S, Philos Mag B 61 (1990) 473. https://doi.org/10.1080/13642819008219288

Moon K I, and Lee K S, J Alloys Compd 291 (1999) 312. https://doi.org/10.1016/S0925-8388(99)00299-6

Zhang F, Lu L, and Lai M O, J Alloys Compd 297 (2000) 211. https://doi.org/10.1016/S0925-8388(99)00568-X

Suryanarayana C, Prog Mater Sci 46 (2001) 1. https://doi.org/10.1016/S0079-6425(99)00010-9

Nayak S S, Kim D H, Pabi S K, and Murty B S, Trans Indian Inst Met 65 (2012) 647. https://doi.org/10.1007/s12666-012-0213-y

Forouzanmehr N, Karimzadeh F, and Enayati M H, J Alloys Compd 471 (2009) 93. https://doi.org/10.1016/j.jallcom.2008.03.121

Chi Y, Gu G, Yu H, and Chen C, Opt Lasers Eng 100 (2018) 23. https://doi.org/10.1016/j.optlaseng.2017.07.006

Milgrāvis M, Kroņkalns G, Nikoluškins R, Beinerts T, Kalvāns M, Bojarevičs A, and Perianu I A, Solid State Phenom 332 (2022) 19. https://doi.org/10.4028/p-9shcqm

Li Y, Zhang Y, Bi J, and Luo Z, Mater Des 83 (2015) 577. https://doi.org/10.1016/j.matdes.2015.06.042

Zhao W, Liu N, Rong J E L, and Zhao D, Adv Eng Mater 19 (2017) 1600866. https://doi.org/10.1002/adem.201600866

Moon K I, Park H S, and Lee K S, J Alloys Compd 325 (2001) 236. https://doi.org/10.1016/S0925-8388(01)01352-4

Kambara M, Uenishi K, and Kobayashi K F, J Mater Sci 35 (2000) 2897. https://doi.org/10.1023/A:1004771808047

García-Martín J, Gómez-Gil J, and Vázquez-Sánchez E, Sensors 11 (2011) 2525. https://doi.org/10.3390/s110302525

Younes A, Powder Metall Met Ceram 61 (2022) 81. https://doi.org/10.1007/s11106-022-00309-6

Younes A, and Kherrouba N, Emerg Mater Res 11 (2022) 268. https://doi.org/10.1680/jemmr.21.00174

Xie S, Yang S, Tian M, Zhao R, Chen Z, Zheng Y, and Takagi T, NDT E Int 138 (2023) 102900. https://doi.org/10.1016/j.ndteint.2023.102900

Cuevas F G, Montes J M, Cintas J, and Gallardo J M, Powder Metall 48 (2013) 365. https://doi.org/10.1179/174329005X78121

Yadav M K, Siddiquee A N, and Khan Z A, Met Mater Int 27 (2021) 2378. https://doi.org/10.1007/s12540-019-00603-w

Belgibayeva A, Abzaev Y, Karakchieva N, Erkasov R, Sachkov V, and Kurzina I, Metals 10 (2020) 859. https://doi.org/10.3390/met10070859

Al-Dabbagh J B, Tahar R M, Harun S A, and Ishak M, Int J Nanoelectron Mater 8 (2015) 23.

Cuevas F G, Cintas J, Montes J M, and Gallardo J M, J Mater Sci 41 (2006) 8339. https://doi.org/10.1007/s10853-006-1029-0

Supriyanto A A, and Daud A R, in AIP Conference Proceedings 1202 (2009) 117. https://doi.org/10.1063/1.3295580.

Supriyanto A A, Widodo W, Tauvana A I, and Syafrizal S, Int J Adv Technol Mech Mechatron Mater 1 (2020) 50. https://doi.org/10.37869/ijatec.v1i2.21

Abada A, Bergheul S, and Younes A, Micro Nano Lett 15 (2020) 1023. https://doi.org/10.1049/mnl.2020.0336

Knaislová A, Novák P, and Prùsa F, Manuf Technol 16 (2016) 1274. https://doi.org/10.21062/ujep/x.2016/a/1213-2489/MT/16/6/1274

Marya M, Marya S, and Priem D, Weld World 49 (2005) 74. https://doi.org/10.1007/BF03263412

Zergoug M, Lebaili S, Boudjellal H, and Benchaala A, NDT E Int 37 (2004) 65. https://doi.org/10.1016/j.ndteint.2003.09.002

Laslouni W, and Azzaz M, Emerg Mater Res 8 (2019) 552. https://doi.org/10.1680/jemmr.18.00139

Tochaee E B, Hosseini H M, and Reihani S S, J Alloys Compd 681 (2016) 12. https://doi.org/10.1016/j.jallcom.2016.04.111

Ghis R, Hammouda A, Ziouche A, Boucherou N, Choucha A, Halimi R, and Benmoussat A, Russian J Nondestruct Test 59 (2023) 292. https://doi.org/10.1134/S1061830922600848

Liu T, Wang W, Qiang W, and Shu G, J Nucl Mater 501 (2018) 1. https://doi.org/10.1016/j.jnucmat.2018.01.028

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical Approval

The manuscript has not been submitted to more than one publication for simultaneous consideration. The submitted work is original and has not been published elsewhere in any form or language.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abada, A., Younes, A. Microstructural and Eddy Current Evaluation of Ball-Milled Nanostructured Aluminum–Titanium Alloys. Trans Indian Inst Met 77, 513–521 (2024). https://doi.org/10.1007/s12666-023-03135-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03135-5