Abstract

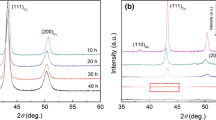

Mechanical alloying of aluminum, copper, zinc, and magnesium metal powders and silicon carbide ceramic powder was performed in a high-energy ball mill working in Spex style at certain amounts and times. It has been tried to investigate the effect of the amount of Cu element and changing alloying time on alloying. The crystal size was calculated using the Scherrer equation, and lattice strain was calculated using the Hall equation with the data fitted with the Gaussian function obtained from the X-Ray Diffraction analysis of the alloyed powder mixtures. Microstructural analysis of samples with different amounts of Cu by weight and different alloying times was performed under a scanning electron microscope. The alloyed powders were sintered in a protective argon atmosphere. SEM Energy-Dispersive Spectroscopy examinations of the sintered samples were made. Vickers microhardness tests of the samples were carried out. Finally, the compression tests were applied to the samples.

Similar content being viewed by others

Data availability

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

References

Suryanarayana C, Progress in Materials Science 46 (2001) 1. https://doi.org/10.1016/S0079-6425(99)00010-9

Sundaresan R, and Froes F H, The Journal of The Minerals, Metals & Materials Society 9 (1987) 22. https://doi.org/10.1007/BF03258604

Matvienko Y I, Polishchuk S S, Rud A D, Popov O Y, Demchenkov S A, and Fesenko O M, Materials Chemistry and Physics 254 (2020) 123437.

Ahn I S, Jung K, Kim S S, and Kim Y Y, Metals and Materials 5 (1999) 619. https://doi.org/10.1007/BF03026314

Starke E A, and Staleyt J T, Progress in Aerospace Sciences 32 (1996) 131. https://doi.org/10.1016/0376-0421(95)00004-6

Sabouni H R, and Sabooni S, Russian Journal of Non-Ferrous Metals 58 (2017) 656. https://doi.org/10.3103/S1067821217060104

Murugesan R, Gopal M, and Murali G, Journal of Applied Research and Technology 495 (2019) 293. https://doi.org/10.1016/j.apsusc.2019.143542

Chen H, Tao K, Yang B, and Zhang J, Transactions of Nonferrous Metals Society of China (English Edition) 19 (2009) 1110. https://doi.org/10.1016/S1003-6326(08)60415-X

Pulido-Suárez P A, Uñate-González K S, Tirado-González J G, Esguerra-Arce A, and Esguerra-Arce J, Journal of Materials Research and Technology 9 (2020) 11769. https://doi.org/10.1016/j.jmrt.2020.08.045

Azimi A, Shokuhfar A, and Zolriasatein A, Materials Science and Engineering A 595 (2014) 124. https://doi.org/10.1016/j.msea.2013.11.094

Rana J K, Sivaprahasam D, Seetharama Raju K, and Subramanya Sarma V, Materials Science and Engineering A 527 (2009) 292. https://doi.org/10.1016/j.msea.2009.08.041

Gültekin G G, Çanakçı A, and Canpolat Ö, Microstructure, and Analysis 12 (2023) 444. https://doi.org/10.1007/s13632-023-00962-2

Shanmugasundaram T, Heilmaier M, Murty B S, and Subramanya Sarma V, Metallurgical and Materials Transactions A 40A (2009) 2798. https://doi.org/10.1007/s11661-009-0005-0

Sattari S, Jahani M, and Atrian A, Powder Metallurgy and Metal Ceramics 56 (2017) 283. https://doi.org/10.1007/s11106-017-9896-2

Randall M. German, Powder Metallurgy & Particulate Materials Processing, 1st Edition, Uyum Ajans, July 2007, 573 pp, Paperback ISBN: 9789759246327.

Enayati M H, Seyed-Salehi M, and Sonboli A, Journal of Materials Science 42 (2007) 5911. https://doi.org/10.1007/s10853-007-1736-1

Williamson G K, and Hall W H, Acta Metallurgica 1 (1953) 22. https://doi.org/10.1016/0001-6160(53)90006-6

Erturun V, Çetin S, and Sahin O, Metals and Materials International 27 (2021) 1662. https://doi.org/10.1007/s12540-019-00583-x

Gencalp Irizalp S, and Saklakoglu N, Engineering 1 (2017) 408. https://doi.org/10.1016/B978-0-12-803581-8.09160-8

Madhusudan S, Sarcar M M M, and Rao N B R M, Journal of Applied Research and Technology 14 (2016) 293. https://doi.org/10.1016/j.jart.2016.05.009

Behret G, Erturun V, and Sahin O, Aircraft Engineering and Aerospace Technology 95 (2023) 1137. https://doi.org/10.1108/AEAT-09-2022-0234

Acknowledgements

The authors express their gratitude to Erciyes University for the financial backing of the current study (Project no: FBA-2018-8068).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sahin, O., Erturun, V. Effect of Cu Content and Alloying Time on Mechanical Alloyed Al-Cu-Mg-Zn&SiC Composites. Trans Indian Inst Met 77, 379–387 (2024). https://doi.org/10.1007/s12666-023-03118-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03118-6