Abstract

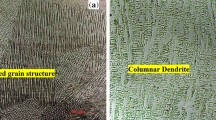

Inconel alloy 617 is a solid-solution-strengthened nickel base super alloy having 55% Ni, 22% Cr, 9% Mo, 12% Co, 1% Al and 0.4% Ti as the main alloying elements. The alloy 617 has very good corrosion resistance and an exceptional combination of high-temperature strength and oxidation resistance. An attempt was made to determine the microstructural effects of thermal ageing on the cold bent Inconel tubes. For this investigation, the Inconel alloy 617 tubes are cold bent at the R/D ratio of 3 in tube bending machine. Then, the cold bent tubes are thermally aged at 750 °C for 1000 h’ duration in the furnace. The specimens extracted from bent tubes are characterized using the transmission electron microscopy (TEM). The gamma prime γ’-Ni3(Al,Ti) phase identified in the TEM micrograph has been further confirmed in the spectroscopy chemical analysis and electron diffraction pattern. Further, STEM-EDS analysis also depicts the presence of chromium-rich M23C6, Ti(C,N) and Mo-rich M6C and Mo-rich M3B2.

Similar content being viewed by others

References

Mathur A, Bhutani O P, Jayakumar T, Dubey D K and Chetal S C, India’s national AUSC mission plan and progress, Advances in Material Technology for Fossil Power Plants proceedings from seventh International conference, published by ASM International, Oct 22–25, 2013, ISBN: 978–1–62708–060–6.

Klöwer J, Alloy 617 and derivatives, Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants Edited by Augusto Di Gianfrancesco, Woodhead Publishing Series in Energy, Number 104, 2017, ISBN 978–0–08–100552–1

Chomette S, Gentzbittel J M, and Viguier B, J Nucl Mater 339 (2010), p. 266. https://doi.org/10.1016/j.jnucmat.2010.01.019

Mankins W L, Hosier J C, and Bassford T H, Metall Trans B 5 (1974), p. 2579. https://doi.org/10.1007/BF02643879

Kihara S, Newkirk J B, Ohtomo A, and Saiga Y, Metall Mater Trans A 11 (1980), p. 1019. https://doi.org/10.1007/BF02654716

Kirchhöfer H, Schubert F and Nickel H, Nucl Technol 66 (1984) p. 139 https://doi.org/10.13182/NT84-A33462

Wu Q, Song H, Swindemann R W, Shingldecker J P and Vasudevan VK Metall Mater Trans A 39 (2008) p. 2569. https://doi.org/10.1007/s11661-008-9618-y

PG-19 Cold Forming of Austenitic Materials, Section I, Rules for construction of power boiler, ASME Boiler and Pressure Vessel Code (2021).

Durand-Charre M, The Microstructure of Superalloys, Gordon and Breach Science Publishers (1997). ISBN 9780203736388.

Bhadeshia H K D, Nickel Based Superalloys, University of Cambridge (2003). https://www.phase-trans.msm.cam.ac.uk/2003/Superalloys/superalloys.html

Song Y Y , Thermodynamic Study on B and Fe Substituted Cr23C6 Using First-Principles Calculations, Master’s thesis submitted to Pohang University of Science and Technology, Korea (2010)

ASME BPVC IIB SB167–18 Standard Specification for Nickel-Chromium-Aluminum Alloys (UNS N06699), Nickel- Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696), Nickel- Chromium-Cobalt-Molybdenum Alloy (UNS N06617), Nickel- Iron-Chromium-Tungsten Alloy (UNS N06674), and Nickel- Chromium-Molybdenum-Copper Alloy (UNS N06235) Seamless Pipe and Tube.

Gane P J, Microstructure and Precipitation Effects in Inconel Alloy 600, Sheffield Hallam University April, Thesis (1992).

Krishna R, Microstructural Investigations of Alloys Used for Power Generation Industries, Ph.D. thesis, University of Leicester, Leister (2010).

Donachie M J, and Donachie S J, Superalloys A Technical Guide, Second Edition, Published by ASM International, (2002) ISBN 0-87170-749-7.

Zhao Y, High temperature aging study on long term aged alloy 617 and alloy 230, Master’s thesis, University of Illinois at Urbana-Champaign (2012)

Kimball O F, Lai G Y, and Reynolds G H, Metall Mater Trans A 7 (1976) 1951. https://doi.org/10.1007/BF02659828

Sroka M, Zielinski A, Jonsta Z and Jonsta P, Metals (2018), p 861.

Yan G, Zhou-bo Z, Rong-can Z, Shu-fang H, and Bo-han W, Trans Nonferrous Met Soc China 25 (2015) 1106. https://doi.org/10.1016/S1003-6326(15)63704-9

Roy A K, Hasan M H, and Pal J, Mater Sci Eng A 520 (2009) 184. https://doi.org/10.1016/j.msea.2009.05.029

Acknowledgements

Author is grateful to Shri S.M. Ramanathan, General Manager (I/c), Bharat Heavy Electricals Limited (BHEL) Tiruchirappalli for providing required approval for publication. Author also thank Shri S. Gowrisankar (GM/WRI, NGA & Labs) and Shri. I. Kalyanasundaram (AGM/WRI) for the constant encouragement and support. Author also thank Shri R. Easwaran (GM I/c retd.) and Dr. G. Ravichandran (GM /WRI retd.) for the valuable discussion and motivation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author has no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gurunathan, V. Microstructural Characterization of Cold Bent and Subsequent Thermal Aged Inconel Alloy 617. Trans Indian Inst Met 76, 3105–3114 (2023). https://doi.org/10.1007/s12666-023-03099-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03099-6