Abstract

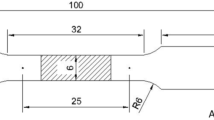

The purpose of this investigation was to determine how tool pin eccentricity affected the strength improvement of FSW weldments AA5754-H111 and AA6101-T6. The irregular joints were created using a square tool pin with eccentricities of 0.1, 0.2, 0.35, 0.5, and 0.6 mm. The analysis of variance (ANOVA) was used to determine the ideal welding parameters and study the impact of various welding parameters on the tensile strength. The study's input parameters are tool rotational speed, tool traversal speed, and tool pin eccentricity, with ultimate tensile strength as the output parameter. Investigations were made into how pin eccentricity affected the mechanical characteristics and microstructural growth of joints. The optimal welding parameters that are determined from this study include tool rotating speed of 900 rpm, tool traverse speed of 40 mm/min, and 0.35 mm tool pin eccentricity. Microstructural investigation revealed that the square tool pin with a 0.35 mm tool pin eccentricity properly mixed both of the base materials.

Similar content being viewed by others

References

Ghiasvand A, Kazemi M, Mahdipour Jalilian M, and Ahmadi Rashid H, Int J Mech Mater Eng 15 (2020) 1–14. https://doi.org/10.1186/s40712-020-00118-y

Aliha M R M, Shahheidari M, Bisadi M, Akbari M, and Hossain S, Int J Adv Manuf Technol 86 (2016) 2551–2565. https://doi.org/10.1007/s00170-016-8341-x

Labus Zlatanovic D, Balos S, Bergmann J P, Rasche S, Pecanac M, and Goel S, Materials 14 (5), (2021) 1157. https://doi.org/10.3390/ma14051157

Kumar R A, and Thansekhar M R, Mater Sci 23 (1), (2017) 78–83. https://doi.org/10.5755/j01.ms.23.1.14132

Aval H J, Mater Des 67 (2015) 413–421. https://doi.org/10.1016/j.matdes.2014.11.055

Palanivel R, Mathews P K, Murugan N, and Dinaharan I, Mater Des 40 (2012) 7–16. https://doi.org/10.1016/j.matdes.2012.03.027

Thomas W M, Johnson K I, and Wiesner C S, Adv Eng Mater 5 (7), (2003) 485–490. https://doi.org/10.1002/adem.200300355

Burek R, Wydrzyński D, Andres J, and Wrońska A, Adv Sci Technol Res J 11 (4), (2017) 333–338. https://doi.org/10.12913/22998624/80938

Xu W, Liu J, Zhu H, and Fu L, Mater Des 47 (2013) 599–606. https://doi.org/10.1016/j.matdes.2012.12.065

Chen Y, Wang H, Wang X, Ding H, Zhao J, Zhang F, and Ren Z, Mater Sci Eng: A 739 (2019) 272–276. https://doi.org/10.1016/j.msea.2018.10.057

Chen Y, Wang H, Li H, Wang X, Ding H, Zhao J, and Zhang F, Metals 9 (7), (2019) 718. https://doi.org/10.3390/met9070718

Mao Y Q, Yang P, Ke L M, Xu Y, and Chen Y H, Acta Metall Sin (Engl Lett) 35 (2021) 745–756. https://doi.org/10.1007/s40195-021-01307-0

Rajakumar S, and Balasubramanian V, J Materi Eng Perform 21 (2012) 809–822. https://doi.org/10.1007/s11665-011-9979-z

Essa A R S, Ahmed M M Z, Mohamed A K Y A, and El-Nikhaily A E, J Mater Res Technol 5 (3), (2016) 234–240. https://doi.org/10.1016/j.jmrt.2015.11.009

Balamurugan S, Jayakumar K, and Subbaiah K, Arab J Sci Eng 46 (2021) 11985–11998. https://doi.org/10.1007/s13369-021-05773-7

Shah L H, Walbridge S, and Gerlich A, Sci Technol Weld Join 24 (6), (2019) 566–578. https://doi.org/10.1080/13621718.2019.1573010

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yogaraj, P., Kasirajan, L. & Senthamaraikannan, B. Effect of Tool Pin Positioning Factors on the Strength Behavior of Dissimilar Joints of AA5754-H111 and AA6101-T6 by Using Friction Stir Welding. Trans Indian Inst Met 76, 3021–3030 (2023). https://doi.org/10.1007/s12666-023-03078-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03078-x