Abstract

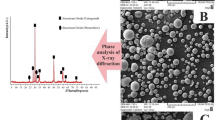

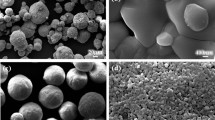

Hot corrosion and oxidation have detrimental effects on thermal barrier coating (TBC) system during service conditions. Hot corrosion behaviour of novel glass–ceramic–YSZ-based triple-layered functionally graded coating on nimonic superalloy was studied at 900 °C using 80 wt.% Na2SO4 + 20 wt.% NaCl molten salt mixture for 100 h. The coating showed no degradation after long exposure at 900 °C and was capable to serve as an effective barrier to the corrosive environment because of its dense structure and impermeability.

Similar content being viewed by others

References

Wu J, Guo H B, Zhou L, Wang L, and Gong S K, J Therm Spray Technol 19 (2010) 1186.

Lakiza S M, Grechanyuk M I, Ruban O K, Redko V P, Glabay M S, Myloserdov O B, Dudnik O V, and Prokhorenko S V, Powder Metall Met Ceram 57 (2018) 82.

Sahith M S, Giridhara G, and Kumar R S, Mater Today Proc 5 (2018) 2746.

Gopal J, Chandan T, and Mahapatra P M M, Met Mater Int 27 (2020) 1947.

Ahmadi-pidani R, Shoja-razavi R, Mozafarinia R, and Jamali H, Ceram Int 38 (2012) 6613.

Xu Z, He L, Mu R, and Zhong X, J Alloys Compd 473 (2009) 509.

Holländer C, Kiliani S, Stamm W, Lüsebrink O, Harders H, Wessel E, and Müller M, Mater Corros 72 (2021) 1643.

Viswanathan V, Dwivedi G, and Sampath S, J Am Ceram Soc 98 (2015) 1769.

Doleker K M, Ozgurluk Y, Kahraman Y, and Karaoglanli A C, Surf Coatings Technol 409 (2021) 126862

Jamali H, Mozafarinia R, Shoja-razavi R, and Ahmadi-pidani R, J Eur Ceram Soc 34 (2014) 485.

Viswanathan V, Dwivedi G, and Sampath S, J Am Ceram Soc 97 (2014) 2770.

Kamalan Kirubakaran A M, Anderson A, Rajasekaramoorthy M, Rama Narasimham P, and Subramanyam P, Mater Today Proc 33 (2020) 954.

Smialek J L, Metall Mater Trans A 49 (2017) 782.

Gonzalez-julian J, Mauer G, Sebold D, and Mack D E, J Am Ceram Soc 103 (2020) 2362.

Magnus C, Cooper D, Jantzen C, Lambert H, Abram T, and Rainforth M, Corros Sci 182 (2021) 109.

Frolenkov K Y, Prot Met Phys Chem Surf 45 (2009) 444.

Li W, Feng M, Liu L, Zhang J, and Hu B, Cheng. Coatings 12 (2022) 1.

Wang X, Chen M, Zhu S, and Wang F, Surf Coatings Technol 270 (2015) 314.

Datta S, and Das S, Bull Mater Sci 28 (2005) 689.

Das S, Datta S, Basu D, and Das G C, Ceram Int 34 (2008) 1215.

Chen X, Gu L, Zou B, Wang Y, and Cao X, Surf Coatings Technol 206 (2012) 2265.

Acknowledgements

The authors acknowledge Aeronautical Research and Development Board (AR&DB) for funding (Project no. 1893). Thanks also go to AcSIR, India, for supporting the research work.

Funding

The authors declare that they have no known funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

Competing interests that have influence on the present work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Parthiban, K., Roy, P. & Ghosh, S. Hot Corrosion Behaviour of Three-Layered Functionally Graded Glass–ceramic–YSZ-based Thermal Barrier Coating System. Trans Indian Inst Met 77, 1407–1412 (2024). https://doi.org/10.1007/s12666-023-03073-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03073-2