Abstract

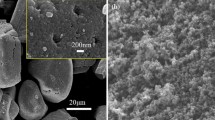

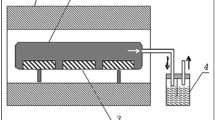

Key parameters (milling time, temperature, time, and reduction atmosphere) on the preparation of tungsten carbide by carbothermic reduction of WO3 were investigated. SEM, XRD, TG/DTA, and hardness tests were used for characterizations. TG/DTA showed that the endothermic reactions related to the 10 h milled WO3 reduction and its conversion to tungsten and tungsten sub-oxides occur between 700 and 826 °C. Subsequently, the formation of tungsten carbide occurs in the temperature range of 1000–1287 °C. The amount of tungsten carbide increases, and the uniformity of the structure improves with an increment in the reduction temperature. The tungsten carbide formation became complete with increasing process time, and the WO3 was converted to tungsten carbide in 6 h. The reduction process can almost be completed in the hydrogen atmosphere. Moreover, results showed that increasing the milling time up to 30 h improves the tungsten carbide formation leading to an improvement in structural homogeneity and an increase in hardness.

Similar content being viewed by others

References

Upadhyaya G S, Cemented tungsten carbides production, properties, and testing, Noyes Publications, Westwood, New Jersey (1998).

Claridge J B, York A P E, Brungs A J, Marquez-Alvarez C, Sloan J, Tsang S C, and Green M L H, J Catal 180 (1998) 85. https://doi.org/10.1006/jcat.1998.2260

Lassner E, and Schubert W D, Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds, Kluwer Academics/Plenum Publishers, New York (1999).

Fang Z Z, Wang X, Ryu T, Hwang K S, and Sohn H Y, Int J Refract Metals Hard Mater 27 (2009) 288. https://doi.org/10.1016/j.ijrmhm.2008.07.011

Sakaki M, Bafghi MSh, Vahdati Khaki J, Zhang Q, and Saito F, Int J Refract Metals Hard Mater 36 (2013) 116. https://doi.org/10.1016/j.ijrmhm.2012.08.002

Sakaki M, Bafghi MSh, Vahdati Khaki J, Zhang Q, Kano J, and Saito F, J Alloys Compd 480 (2009) 824. https://doi.org/10.1016/j.jallcom.2009.02.088

Alonso F C N, Morales M L Z, Salas A U, and Becerril J E B, Int J Miner Process 20 (1987) 137. https://doi.org/10.1016/0301-7516(87)90022-6

Bolokang S, Banganayi C, and Phasha M, Int J Refract Metals Hard Mater 28 (2010) 211. https://doi.org/10.1016/j.ijrmhm.2009.09.006

Decker S, Löfberg A, and Bastin J M, Catal Lett 44 (1997) 229–239. https://doi.org/10.1023/A:1018985227289

Tan G L, Adv Mater Res 66 (2009) 135.

S. Vallance, Microwave synthesis and mechanistic examination of the transition metal carbides, Ph D Thesis, University of Nottingham, (2009).

Pervikov A V, Krinitcyn M G, Glazkova E A, Rodkevich N G, and Lerner M I, Int J Refract Metals Hard Mater 103 (2022) 105733. https://doi.org/10.1016/j.ijrmhm.2021.105733

Pak A Y, Shanenkov I I, Mamontov G Y, and Kokorina A I, Int J Refract Metals Hard Mater 93 (2020) 105343. https://doi.org/10.1016/j.ijrmhm.2020.105343

Wang K F, Sun G D, Wu Y D, Zhang G H, and Chou K C, Int J Refract Metals Hard Mater 84 (2019) 104975. https://doi.org/10.1016/j.ijrmhm.2019.104975

Wu Y, Dang J, Lv Z, and Zhang R, Int J Refract Metals Hard Mater 76 (2018) 99. https://doi.org/10.1016/j.ijrmhm.2018.06.002

Tripathy H, Sudha C, Paul V T, Thirumurugesan R, Prasanthi T N, Sundar R, Vijayashanthi N, Parameswaran P, and Raju S, Int J Refract Metals Hard Mater 104 (2022) 105804. https://doi.org/10.1016/j.ijrmhm.2022.105804

Enneti R K, Int J Refract Metals Hard Mater 53 (2015) 111. https://doi.org/10.1016/j.ijrmhm.2015.06.011

Chen W H, Nayak P K, Lin H T, Chang M P, and Huang J L, Int J Refract Metals Hard Mater 47 (2014) 44. https://doi.org/10.1016/j.ijrmhm.2014.06.015

Yang R, Xing T, Xu R, and Li M, Int J Refract Metals Hard Mater 29 (2011) 138. https://doi.org/10.1016/j.ijrmhm.2010.09.008

Chen Y, Yang R, Zhang C, Song J, Che Y, and He J, Int J Refract Metals Hard Mater 106 (2022) 105869. https://doi.org/10.1016/j.ijrmhm.2022.105869

Kong Y, Liu Y, Ye J, and Li J, Int J Refract Metals Hard Mater 98 (2021) 105557. https://doi.org/10.1016/j.ijrmhm.2021.105557

Ma J, and Zhu S G, Int J Refract Metals Hard Mater 28 (2010) 623. https://doi.org/10.1016/j.ijrmhm.2010.06.004

Yusoff M I, and Hussain Z, Int J Mater Mech Manuf 1 (2013) 283.

Ma J, Zhu S G, Ding H, and Gu W S, Defect Diffus Forum 312 (2011) 248. https://doi.org/10.4028/www.scientific.net/DDF.312-315.248

Zakeri M, and Rahimipour M R, Adv Powder Technol 23 (2012) 31. https://doi.org/10.1016/j.apt.2010.12.001

Funding

Funding was provided by University of Tehran (Grant No. 6409).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Beighi, M., Pourabdoli, M., Raygan, S. et al. Direct Synthesis of Tungsten Carbide by Solid-State Carbothermic Reduction of Tungsten Trioxide. Trans Indian Inst Met 76, 3455–3461 (2023). https://doi.org/10.1007/s12666-023-03025-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03025-w