Abstract

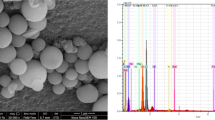

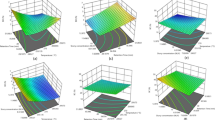

In this study, optimization of oil agglomeration parameters of Beyşehir-Bayavşar lignite using Box–Behnken design (BBD) was investigated. BBD model predicted responses, the coefficient of determination R2 for the percentage of ash% and combustible recovery% (CR) of the agglomerates was obtained as 0.97 and 0.90, respectively. These results showed a good correlation between the calculated and observed values. The estimated the percentage of ash content and CR% values were determined as 15.81% and 73.73%, respectively. The best results were obtained in test 22, the zeta potential value was − 11.61 mV, the contact angle was 107°, and the calorific value was 4702 kcal/kg at pH 3.

Similar content being viewed by others

References

Mehrotra V P, Sastry K V S, and Morey B W, Int J Miner Process 11 (1983) 175. https://doi.org/10.1016/0301-7516(83)90025-X

Sahinoglu E, and Uslu T, Fuel Process Technol 128 (2014) 211. https://doi.org/10.1016/j.fuproc.2014.07.015

Kumar S, Chary G H V C, and Dastidar M, Fuel 141 (2015) 9. https://doi.org/10.1016/j.fuel.2014.09.119

Cebeci Y, and Sonmez I, Fuel 85 (2006) 289. https://doi.org/10.1016/j.fuel.2005.07.017

Rao T C, Vanangamudi M, and Rao K H, Int J Miner Process 9 (1982) 235. https://doi.org/10.1016/0301-7516(82)90030-8

Bensley C N, Swanson A R, and Nicol S K, Int J Miner Process 4 (1977) 173. https://doi.org/10.1016/0301-7516(77)90024-2

Chary G H V C, and Dastidar M, Fuel 98 (2012) 259. https://doi.org/10.1016/j.fuel.2012.03.027

Aslan N, Fuel 109 (2013) 373. https://doi.org/10.1016/j.fuel.2013.02.069

Capes C E, AIME 2 (1980) 1442.

Keller D V, and Burry W, Colloids Surf 22 (1987) 37. https://doi.org/10.1016/0166-6622(87)80004-5

Capes C E, and Jonasson K A, Surfactant Sci Ser 32 (1988) 1.

Gurses A, Doymus K, and Bayrakceken S, Fuel 75 (1996) 1175. https://doi.org/10.1016/0016-2361(96)00077-4

Sahinoglu E, and Uslu T, Energy Convers Manag 49 (2008) 3684. https://doi.org/10.1016/j.enconman.2008.06.026

Skarvelakis C, Hazi M, and Antonini G, Sep Sci Technol 30 (1995) 2519. https://doi.org/10.1080/01496399508021399

Yadav A M, Nikkam S, and Gajbhiye P, Energy Sour Part A 38 (2016) 3612. https://doi.org/10.1080/15567036.2016.1196271

Carbini P, Ciccu R, Ghiani M, and Satta F, Coal Prep 11 (1992) 11. https://doi.org/10.1080/07349349208905204

Garcia A B, Vega J M G, and Martinez-Tarazona M R, Fuel 74 (1995) 1692. https://doi.org/10.1016/0016-2361(95)00149-Y

Valdes A F, and Garcia A B, Fuel 85 (2006) 607. https://doi.org/10.1016/j.fuel.2005.08.011

Unal I, and Aktas Z, Fuel Process Technol 69 (2001) 141. https://doi.org/10.1016/S0378-3820(00)00137-5

Duzyol S, Powder Technol 274 (2015) 1. https://doi.org/10.1016/j.powtec.2015.01.011

Chary G H V C, and Dastidar M, Fuel 106 (2013) 285. https://doi.org/10.1016/j.fuel.2012.12.002

Labuschagne B C J, Coal Prep 3 (1986) 1. https://doi.org/10.1080/07349348608905270

Guy D W, Crawford R J, and Mainwaring D E, Fuel 71 (1992) 935. https://doi.org/10.1016/0016-2361(92)90245-J

Ozkan A, Aydogan S, and Yekeler M, Int J Miner Process 76 (2005) 83. https://doi.org/10.1016/j.minpro.2004.12.003

Unal I, and Ersan G M, Fuel Process Technol 87 (2005) 71. https://doi.org/10.1016/j.fuproc.2005.08.001

Sahinoglu E, and Uslu T, Fuel Process Technol 116 (2013) 332. https://doi.org/10.1016/j.fuproc.2013.07.016

Ferreira S L C, Bruns R E, Ferreira H S, Matos G D, David J M, Brandao G C, da Silva E P, Portugal L A, dos Reis P S, Souza A S, and dos Santos W N L, Anal Chim Acta 597 (2007) 179.

Talib N A A, Salam F, Yusof N A, Ahmad S A A, and Sulaiman Y, J Electroanal Chem 787 (2017) 1. https://doi.org/10.1016/j.jelechem.2017.01.032

Yadav A M, Nikkam S, Gajbhiye P, and Tyeb M H, Int J Miner Process 163 (2017) 55. https://doi.org/10.1016/j.minpro.2017.04.009

Yadav A M, Chaurasia R C, Suresh N, and Gajbhiye P, Fuel 220 (2018) 826. https://doi.org/10.1016/j.fuel.2018.02.040

Chary G H V C, and Dastidar M, Fuel 89 (2010) 2317. https://doi.org/10.1016/j.fuel.2009.12.016

Aslan N, and Unal I, Fuel 88 (2009) 490. https://doi.org/10.1016/j.fuel.2008.10.039

Aslan N, and Unal I, Fuel Process Technol 92 (2011) 1157. https://doi.org/10.1016/j.fuproc.2010.05.029

Agacayak T, and Duzyol S, J Int Sci Publ Mater Methods Technol 12 (2018) 179.

Duzyol S, Part Sci Technol 3 (2018) 351. https://doi.org/10.1080/02726351.2016.1248264

He J, Zhu L, Liu C, and Bai Q, Fuel 254 (2019) 115560. https://doi.org/10.1016/j.fuel.2019.05.143

Shukla D, and Venugopal R, Powder Technol 346 (2019) 316. https://doi.org/10.1016/j.powtec.2019.02.001

Polat S, and Sayan P, Adv Powder Technol 30 (2019) 2396. https://doi.org/10.1016/j.apt.2019.07.022

Bagheri A R, Ghaedi M, Asfaram A, Jannesar R, and Goudarzi A, Ultrason Sonochem 35 (2017) 112. https://doi.org/10.1016/j.ultsonch.2016.09.008

Box G E B, Hunter W G, and Hunter J S, Statistics for experimenters, Willey, New York (1978).

Montgomery D C, Design and analysis of experiments, Wiley, New York (2001).

Yildiz N, Ates C, Yilmaz M, Demir D, Yildiz A, and Calimli A, Green Process Synth 3 (2014) 259. https://doi.org/10.1515/gps-2014-0024

Korbahti B K, and Tasyurek S, Environ Sci Pollut Res 22 (5), (2015) 3265. https://doi.org/10.1007/s11356-014-3101-7

Souzaa A S, Walter N L, Santos D, and Sergio L C F, Spectrochim Acta Part B 60 (2005) 737. https://doi.org/10.1016/j.sab.2005.02.025

Joglekar A M, and May A T, Cereal Foods World 32 (1987) 857.

Vazifeh Y, Jorjani E, and Bagherian A, Trans Nonferrous Met Soc China 20 (2010) 2371. https://doi.org/10.1016/S1003-6326(10)60657-7

Leong Y K, and Boger D V, J Colloid Interface Sci 136 (1990) 249. https://doi.org/10.1016/0021-9797(90)90095-6

Duzyol S, and Sensogut C, Fuel Process Technol 137 (2015) 333. https://doi.org/10.1016/j.fuproc.2015.03.021

Ozdemir O, Taran E, Hampton M A, Karakashev S I, and Nguyen A V, Int J Miner Process 92 (2009) 177. https://doi.org/10.1016/j.minpro.2009.04.001

S. Duzyol, C. Sensogut, A.O. Aksu, H.S. Erisir, K. Aspir, Benefication of Tuncbilek lignites by oil agglomeration, in M.E. Bilir, K. Kel, E. Kaymakci (Eds.). Proceedings of the 19th Coal Congress of Turkey, Zonguldak/Turkey. 2014, pp. 237–244.

Duzyol S, CU J Fac Eng Archit 31 (2016) 77.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agacayak, T. Modeling and Optimization of the Oil Agglomeration Parameters of Low-Calorific Value Lignite by Box–Behnken Design (BBD) Method. Trans Indian Inst Met 76, 2243–2251 (2023). https://doi.org/10.1007/s12666-023-02940-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02940-2