Abstract

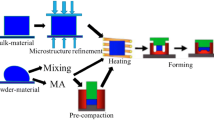

With advantages of powder metallurgy and semi-solid forming, Semi-solid powder rolling (SPR) as a novel technology was proposed and has been widely used to produce high-performance strips currently. As SPR is an extremely complex process and influenced by many factors, consequently it is necessary to be researched by the simulation method to study the forming process and various influence laws, in order to save experimental time and cost. Therefore, in this work, a two-dimensional model was built based on the Shima-porous yield criterion by using Marc software, considering the effect of temperature and relative-density on thermal conductivity, heat capacity, elastic modulus and Poisson's ratio. The semi-solid rolling process of Al–Cu–Mg alloy powder was simulated by the model, and the relative-density and rolling-force of strips were calculated and proven by experiments, which are basically consistent with the measured values. Based on this model, the influence of main parameters on SPR strips was analyzed. The results show that the rolling temperature of strips increases with the roller temperature increasing, and changes little with the variation of the compression ratio, rotational velocity and friction factor. The rolling-force reduces with the increase in roller temperature and the decrease in compression ratio, rotational velocity and friction factor. The relative-density rises as the four parameters increase. According to the results, it is suggested that a moderate roller temperature, a relatively large compression ratio and a small rotational velocity are recommended during the actual rolling, which provides a theoretical guidance for semi-solid powder forming experiments.

Similar content being viewed by others

References

Chen L, Qi Y, Fei Y, Liu Y, and Du Z, Mater Trans 61 (2020) 1239.

Li M, Chen Q, Zhao G, Huang Z, Tao J, Wan Y, and Wang H, Appl Phys A 125 (2019) 1.

Liu J, Jiang D, Zhou X, Wang Y, Liu X, Xin H, Jiang Y, Yang L, Zhang Y, Huang Z, and Feng D, Powder Technol 343 (2019) 95.

Li P B, Chen T J, and Qin H, Mater Des 112 (2016) 34.

Liu Y Z, Luo X, and Li Z L, J Mater Process Technol 214 (2014) 165.

Mo Z Q, Liu Y Z, Jia H F, and Min W U, Trans Nonferrous Met Soc China 25 (2015) 3181.

Hamilton R W, Zhu Z, Dashwood R J, and Lee P D, Compos: Part A 34 (2003) 333.

Luo S J, Jiang J F, Zu L J, and Teng D D, Spec Cast Nonferrous Alloys (2002) 603.

Wu Y F, and Kim G Y, Powder Technol 214 (2011) 252.

Wu Y F, and Kim G Y, J Mater Process Technol 216 (2015) 484.

Wu M, Liu Y, Wang T, and Yu K, Mater Sci Eng A 674 (2016) 144.

Luo X, Liu Y, Gu C, and Li Z, Powder Technol 261 (2014) 161.

Ren J., Luo X., Cai X.W., et al.Powder Metal Ind 6: (2022) 49.

Liu G C, Shi Y S, Wei Q S, and Xue P J, J Central South Univ 19 (2012) 55.

Shima S, and Oyane M, Int J Mech Sci 18 (1976) 285.

Zhao Z.H., Xia W., Zhou Z.Y., et al.Mach Des Manuf (2009)120.

Acknowledgments

The authors thank the financial supports from Science and Technology Planning Projects of Guangzhou (202102080110), Sichuan Science and Technology Program (2020YFH0151), Scientific and Technological Research Program of ChongqingMunicipal Education Commission (KJQN202103203) and Guangdong Province Nature Foundation of China, grant number 2022A1515011065.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, M., Liu, J., Luo, X. et al. Numerical Simulation and Parameter Optimization for Semi-solid Powder Rolling of Al–Cu–Mg Alloy. Trans Indian Inst Met 76, 1771–1780 (2023). https://doi.org/10.1007/s12666-023-02882-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02882-9