Abstract

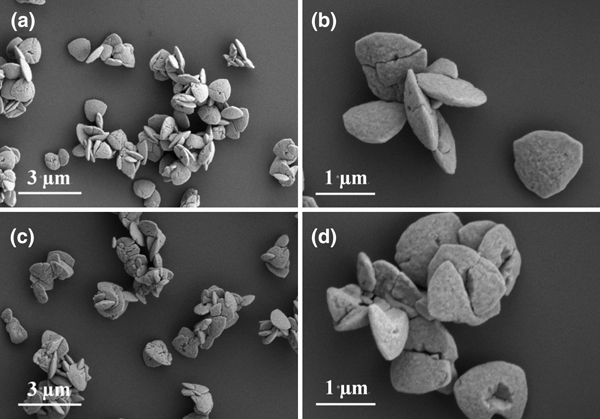

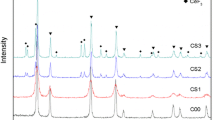

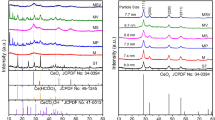

In this work, CeO2 nanosheet was facile synthesized via a parallel flow precipitation route, using cerium chloride trihydrate and sodium carbonate as the cerium source, without using any surfactants and templates. The results show that the CeO2 nanosheets have a median particle size (D50) of 118 nm, a range (R) of 0.69, a surface area of 3.01 m2/g, a pore diameter of 27.96 nm, a pore volume of 0.02 cm3/g, and a loss on ignition (L.O.I.) of < 1%. Furthermore, the activation energy of CeO2 nanocrystal growth during the calcination process is about 30.5 kJ/mol, indicating that the controlling link of the crystallite growth is the interfacial chemical reaction. Ostwald ripening (OR) mechanism has a synergistic effect with Oriented attachment (OA) mechanism during the process of nucleation and growth of Ce2(CO3)3 crystal grains.

Similar content being viewed by others

References

Kang Y, Zhang Y H, Sun P P, Huang P B, Yu X, Shi Q, Tian B, Gao J, and Shi F N, Solid State Ionics 350 (2020) 115310

Lan Y P, and Sohn H Y, Ceram Int 44 (2018) 3847.

Zmorayova K, Vojtkova L, Hlasek T, Plechacek J, and Diko P, Supercond Sci Tech 33 (2020) 034005

Vazque V E, Lopez Z L, and Martinez V H, J Appl Polym Sci 137 (2020) 48663.

Mueen R, Morlando A, Qutaish H, Lerch M, Cheng Z, and Konstantinov K, J Mater Sci 55 (2020) 6834.

Leach F C P, Davy M, and Terry B, Fuel 288 (2021) 119636

Lebedeva M I, Arzhatkina L A, Dzidziguri E L, and Sidorova E N, Nanotechnol Russ 9 (2014) 73.

Putla S, Amin M H, Reddy B M, Nafady A, AlFarhan K A, and Bhargava S K, ACS Appl Mater Inter 7 (2015) 16525.

Zhang D, Pan C, Shi L, Huang L, Fang J, and Fu H, Micropor Mesopor Mat 117 (2009) 193.

Lu F, Meng F, Wang L, Luo J, and Sang Y, Mater Lett 73 (2012) 154.

Yu T, Lim B, and Xia Y, Angew Chem 122 (2010) 4586.

Li C R, Sun Q T, Lu N P, Chen B Y, and Dong W J, J Cryst Growth 343 (2012) 95.

Zhang J, Li X C, Chen P A, and Zhu B Q, Materials 11 (2018) 1632.

Morlando A, Borrás M C, Rehman Y, Bakand S, Barker P, Sluyter R, and Konstantinov K, J Mater Chem B 8 (2020) 4016.

Hassanzadeh T S A, Mazaheri M, Aminzare M, and Sadrnezhaad S K, J Alloy Compd 491 (2009) 499.

Khan M, Khan W, Ahamed M, and Alhazaa A N, Sci Rep-UK 7 (2017) 1.

Li Y X, Chen W F, Zhou X Z, Gu Z Y, and Chen C M, Mater Lett 59 (2005) 48.

Li J Z, Zhong J B, Hu W, Lu Y, Zeng J, and Shen Y C, Mat Sci Semicon Proc 16 (2013) 143.

Ren S, and Gou L, Adv Appl Ceram 120 (2021) 95.

Li Y L, Lv P, Li S W, Li T T, Yin S H, Zhang L B, Xu Z Y, and Zhang G G, JOM 74 (2022) 909.

Qin W B, Yuan Z Y, Gao H L, and Meng F L, Sensors 20 (2020) 3353.

Guen M J L, Hill S, Smith D, Theobald B, Gaugler E, Barakat A, and Mayer L C, Front Chem 7 (2019) 735.

Han X G, Li L, and Wang C, CrystEngComm 14 (2012) 1939.

Hassanzadeh T S A, Mazaheri M, Aminzare M, and Sadrnezhaad S, J Alloy Compd 491 (2010) 499.

Lv P, Zhang L J, Koppala S, Chen K H, and Yin S H, ACS Omega 5 (2020) 21338.

Zhang J, Huang F, and Lin Z, Nanoscale 2 (2010) 18.

Lai A, He Q, Rao M, Gao G H, and Xiao Y F, J Solid State Chem 290 (2020) 121593

Acknowledgements

Financial support from the following programs is gratefully acknowledged: National Natural Science Foundation of China (Grant No. 52264051) and Yunnan Ten Thousand Talents Plan Young & Elite Talents Project (Grant No. YNWR-QNBJ-2018-323).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ran, J., Yao, J., Li, T. et al. Facile Synthesis of CeO2 Nanosheets via a Parallel Flow Precipitation Route. Trans Indian Inst Met 76, 1495–1507 (2023). https://doi.org/10.1007/s12666-022-02849-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02849-2