Abstract

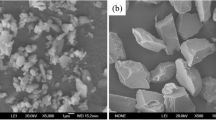

Freeze-casting (FC) is an innovative technique for developing porous ceramics with distinctive pore structures. The homogeneous alumina slurry with increasing solid concentration (50, 60, 70, and 80 wt.%) in water prepared by ball milling has been frozen and subsequently sublimed to produce green bodies, which are further sintered to fabricate lamellar-structured porous ceramics. As the solid content increases from 50 to 80 wt.%, the slurry viscosity increases, while porosity decreases from 70 to 30%. Microstructural investigations of porous ceramics revealed alternating layers of open porosity and a dense lamellar structure. The pores formed during FC were infiltrated with Poly (methyl methacrylate) (PMMA) polymer and composites were characterised by density, compressive strength and hardness measurement. The findings demonstrate that FC composite structural characteristics may be specifically engineered, making them the perfect choice for applications that is needed for high porosity at low or medium load-bearing capacity.

Similar content being viewed by others

References

Shao G, Hanaor DAH, Shen X, Gurlo A, Adv. Mater. 32 (2020). https://doi.org/10.1002/adma.201907176.

Li W L, Lu K, and Walz J Y, Int. Mater. Rev. 57 (2012) 37. https://doi.org/10.1179/1743280411Y.0000000011

Araki K, and Halloran J W, J. Am. Ceram. Soc. 87 (2004) 1859. https://doi.org/10.1111/j.1151-2916.2004.tb06331.x

Aneziris C G, Schärfl W, and Ullrich B, J. Eur. Ceram. Soc. 27 (2007) 3191. https://doi.org/10.1016/j.jeurceramsoc.2007.01.006

Porter M M, McKittrick J, and Meyers M A, Jom. 65 (2013) 720. https://doi.org/10.1007/s11837-013-0606-3

Deville S, Materials (Basel). 3 (2010) 1913. https://doi.org/10.3390/ma3031913

Deville S, Saiz E, Nalla R K, and Tomsia A P, Science. 311 (2006) 515. https://doi.org/10.1126/science.1120937

Deville S, Adv. Eng. Mater. 10 (2008) 155. https://doi.org/10.1002/adem.200700270

Deville S, Saiz E, and Tomsia A P, Biomaterials. 27 (2006) 5480. https://doi.org/10.1016/j.biomaterials.2006.06.028

Zuo K H, Zeng Y P, and Lin Q L, Adv. Mater. Res. 518–523 (2012) 665. https://doi.org/10.4028/www.scientific.net/AMR.518-523.665

Lebreton K, Rodríguez-Parra J M, Moreno R, and Nieto M I, Adv. Appl. Ceram. 114 (2015) 296. https://doi.org/10.1179/1743676115Y.0000000006

Lasalle A, Guizard C, Leloup J, Deville S, Maire E, Bogner A, Gauthier C, Adrien J, and Courtois L, J. Am. Ceram. Soc. 95 (2012) 799. https://doi.org/10.1111/j.1551-2916.2011.04993.x

Seuba J, Maire E, Adrien J, Meille S, and Deville S, Open Ceramics 8 (2021) 100195. https://doi.org/10.1016/j.oceram.2021.100195

Schoof H, Apel J, Heschel I, and Rau G, J. Biomed. Mater. Res. 58 (2001) 352. https://doi.org/10.1002/jbm.1028

Barr S A, and Luijten E, Acta Mater. 58 (2010) 709. https://doi.org/10.1016/j.actamat.2009.09.050

Li D, and Li M, J. Porous Mater. 19 (2012) 345. https://doi.org/10.1007/s10934-011-9480-y

Zeng J, Zhang Y, Zhou K C, and Zhang D, Trans. Nonferrous Met. Soc. China (English Ed.) 24 (2014) 718. https://doi.org/10.1016/S1003-6326(14)63116-2

Kim K H, Kim D H, Ryu S C, Yoon S Y, and Park H C, J. Compos. Mater. 54 (2020) 1527. https://doi.org/10.1177/0021998316636460

Porter M M, Yeh M, Strawson J, Goehring T, Lujan S, Siripasopsotorn P, Meyers M A, and McKittrick J, Mater. Sci. Eng. A. 556 (2012) 741. https://doi.org/10.1016/j.msea.2012.07.058

Preiss A, Su B, Collins S, and Simpson D, J. Eur. Ceram. Soc. 32 (2012) 1575. https://doi.org/10.1016/j.jeurceramsoc.2011.12.031

Liu G, and Button T W, Ceram. Int. 39 (2013) 8507. https://doi.org/10.1016/j.ceramint.2013.02.101

Tang Y, Miao Q, Qiu S, Zhao K, and Hu L, J. Eur. Ceram. Soc. 34 (2014) 4077. https://doi.org/10.1016/j.jeurceramsoc.2014.05.040

Nakazawa H, Yamada H, Fujita T, Ito Y, Clay Sci. 6 (1987) 269. https://doi.org/10.11362/jcssjclayscience1960.6.269

Hunger P M, Donius A E, and Wegst U G K, Acta Biomater. 9 (2013) 6338. https://doi.org/10.1016/j.actbio.2013.01.012

Hunger P M, Donius A E, and Wegst U G K, J. Mech. Behav. Biomed. Mater. 19 (2013) 87. https://doi.org/10.1016/j.jmbbm.2012.10.013

Munch E, Saiz E, Tomsia A P, and Deville S, J. Am. Ceram. Soc. 92 (2009) 1534. https://doi.org/10.1111/j.1551-2916.2009.03087.x

Shen P, Xi J, Fu Y, Shaga A, Sun C, and Jiang Q, Acta Metall. Sin. (English Lett.) 27 (2014) 944. https://doi.org/10.1007/s40195-014-0157-9

Hu L, Zhang Y, Dong S, Zhang S, and Li B, Ceram. Int. 39 (2013) 6287. https://doi.org/10.1016/j.ceramint.2013.01.050

Geng S L, Shen P, Hu Z J, Guo R F, and Jiang Q C, J. Eur. Ceram. Soc. 38 (2018) 2605. https://doi.org/10.1016/j.jeurceramsoc.2018.01.039

Jing L, Zuo K, Fuqiang Z, Chun X, Yuanfei F, Jiang D, and Zeng Y P, Ceram. Int. 36 (2010) 2499. https://doi.org/10.1016/j.ceramint.2010.07.005

Acknowledgements

The authors would like to express their heartfelt appreciation to The Director, ARDE, Pune, and Vice-Chancellor, DIAT, Pune, for their assistance with this project. In addition, the DRDO's financial assistance as an SRF fellowship is appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors report there are no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dixit, P., Rawal, B., Panda, H.S. et al. Freeze-Casted Porous Lamellar-Structured Alumina Ceramics and Polymer-Infiltrated Composites: Synergistic Enhancement of Structural Properties. Trans Indian Inst Met 76, 1211–1219 (2023). https://doi.org/10.1007/s12666-022-02831-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02831-y