Abstract

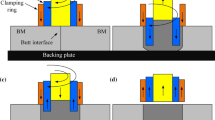

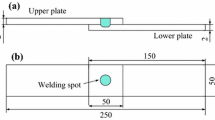

In this work, refill friction stir spot welding (RFSSW) is innovatively applied to butt weld 6082 Al alloys. The effect of the refilling time on the microstructure and properties of the welded joints was studied. The results show that for the 6082 Al alloy with a thickness of 2 mm, a tool plunge depth of 1.6 mm can successfully avoid the incomplete bonding at the joint bottom. Cracks, formed by insufficient bonding, appear at the tool retraction paths when using the short refilling times of 3 s and 4 s. A prolonged refilling time of 5 s can eliminate the crack due to sufficient diffusion time. The pin affected zone (PAZ) has coarser grains than the sleeve affected zone (SAZ) due to the insufficient tool stirring action. Prolonged refilling time results in coarser grains, lower hardness and higher tensile strength of the joints. The maximum tensile strength of 262.2 MPa is obtained when the refilling time of 5 s is used, and the joint fails at the heat affected zone (HAZ) under such a condition.

Similar content being viewed by others

References

Matsuda T, Ogaki T, Hayashi K, Iwamoto C, Nozawa T, Ohata M, and Hirose A, Mater Des 213 (2022) 110344.

Ikumapayi O M, and Akinlabi E T, Mater Today Proc 18 (2019) 2201.

Yapici G G, and Ibrahim I J, J Mater Res Technol 11 (2021) 40.

Fu B, Shen J, Suhuddin U F H R, Chen T, dos Santos J F, Klusemann B, and Rethmeier M, Scr Mater 203 (2021) 114113.

Zhang C, Cao J, and Shirzadi A A, Sci Technol Weld Join 26 (2021) 236.

Chen D, Li J, Xiong J, Shi J, Dou J, and Zhao H, J Mater Res Technol 12 (2021) 1243.

Xu Z, Li Z, Ji S, and Zhang L, J Mater Sci Technol 34 (2018) 878.

Li Z, Ji S, Ma Y, Chai P, Yue Y, and Gao S, Int J Adv Manuf Technol 86 (2016) 1925.

Shen Z, Yang X, Zhang Z, Cui L, and Li T, Mater Des 44 (2013) 476.

Shi Y, Yue Y, Zhang L, Ji S, and Wang Y, Trans Indian Inst Met 71 (2018) 139.

Yue Y, Shi Y, Ji S, Wang Y, and Li Z, J Mater Eng Perform 26 (2017) 5064.

Gera D, Fu B, Suhuddin U F H R, Plaine A, Alcantara N, dos Santos J F, and Klusemann B, J Mater Res Technol 13 (2021) 2272.

Zou Y, Li W, Xu Y, Yang X, Chu Q, and Shen Z, Mater Charact 183 (2022) 111594.

Li G, Zhou L, Luo L, Wu X, and Guo N, J Mater Res Technol 8 (2019) 4115.

Cao J Y, Wang M, Kong L, Zhao H X, and Chai P, Mater Charact 128 (2017) 54.

Fu B, Shen J, Suhuddin U F H R, Pereira A A C, Maawad E, dos Santos J F, Klusemann B, and Rethmeier M, Mater Des 209 (2021) 109997.

Vacchi G S, Silva R, Plaine A H, Suhuddin U F H, Alcântara N G, Sordi V L, and Rovere C A D, Mater Today Commun 22 (2020) 100759.

Li P, Chen S, Dong H, Ji H, Li Y, Guo X, Yang G, Zhang X, and Han X, J Manuf Process 49 (2020) 385.

Ding Y, Shen Z, and Gerlich A P, J Manuf Process 30 (2017) 353.

Shen Z, Ding Y, Gopkalo O, Diak B, and Gerlich A P, J Mater Process Technol 252 (2018) 751.

Cao J Y, Zhang C C, Xing Y F, and Wang M, J Mater Process Technol 284 (2020) 116760.

Shen Z, Li W Y, Ding Y, Hou W, Liu X C, Guo W, Chen H Y, Liu X, Yang J, and Gerlich A P, J Manuf Process 49 (2020) 260.

Shen Z, Ding Y, Chen J, Shalch Amirkhiz B, Wen J Z, Fu L, and Gerlich A P, J Mater Sci Technol 35 (2019) 1027.

Wang X, Morisada Y, and Fujii H, Mater Sci Eng A 809 (2021) 141005.

Memon S, Paidar M, Mehrez S, Cooke K, Ojo O O, and Lankarani H M, Results Phys 22 (2021) 103962.

Lin Y, and Lin C, Corros Sci 180 (2021) 109203.

Suryanarayanan R, and Sridhar V G, Mater Today Proc 37 (2021) 2695.

Tier M D, Rosendo T S, dos Santos J F, Huber N, Mazzaferro J A, Mazzaferro C P, and Strohaecker T R, J Mater Process Technol 213 (2013) 997.

Li Z, Gao S, Ji S, Yue Y, and Chai P, J Mater Eng Perform 25 (2016) 1673.

Cho J H, Kim W J, and Lee C G, Mater Sci Eng A 597 (2014) 314.

Hamada A S, Järvenpää A, Ahmed M M Z, Jaskari M, Wynne B P, Porter D A, and Karjalainen L P, Mater Sci Eng A 642 (2015) 366.

Wan L, Huang Y, Lv Z, Lv S, and Feng J, Mater Des 55 (2014) 197.

Wan L, Huang Y, Guo W, Lv S, and Feng J, J Mater Sci Technol 30 (2014) 1243.

Kumar R, Dhami S S, and Mishra R S, Mater Today Proc 45 (2021) 5368.

Aydin H, Tuncel O, Umua Y, and Bayram A, Indian J Eng Mater Sci 24 (2017) 215.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yinghui, L., Deyun, Y. Effect of Refilling Time on the Microstructure and Mechanical Properties Refill Friction Stir Spot Welded 6082 Al Alloy Butt Joint. Trans Indian Inst Met 75, 2673–2682 (2022). https://doi.org/10.1007/s12666-022-02637-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02637-y