Abstract

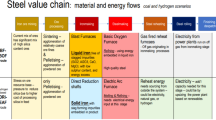

Following the international climate change policy and the major use of coal-based blast furnace–basic oxygen furnace (BF–BOF) in the steel sector, with an average emission of 2.0 t CO2/t steel, alternative processing routes must be considered to reduce the emission intensities. An approach of progressive amalgamation with alternative gas and renewable energy-based processes is indicated for a coal-based sector. The approach also retains coal use for major production with technology changes like smelting reduction technology, HISARNA with carbon capture and storage, or top gas recycling blast furnace. Combining renewable energy-based ‘green electrolytic hydrogen’ processes with/without natural gas with existing coal-based processing is an important option in achieving global climate change targets for emission reduction. Capacity limitations of alternative processing routes and high green hydrogen costs are hurdles to overcome in progressive amalgamation. An approach to redesigning mixed circuits for minimizing sectoral emissions involving BF–BOF with available scrap is presented.

Similar content being viewed by others

Abbreviations

- 2DS:

-

Two-Degree centigrade Scenario

- 45Q:

-

Internal Revenue Code of a tax credit incentivizing carbon capture and sequestration or utilization in the USA.

- BAT:

-

Best Available Technology

- BAU:

-

Business As Usual

- CAGR:

-

Compounded Annual Growth Rate

- CCS:

-

Carbon Capture and Storage

- CCU:

-

Carbon Capture and Utilization

- CCUS:

-

Carbon capture Utilization and Storage

- DR:

-

Direct Reduction processes

- DRI:

-

Direct Reduced Iron

- DRI–EAF:

-

Direct Reduced Iron–Electric Arc Furnace process

- ENERGION ZR:

-

HYL Direct Reduction Shaft furnace Technology jointly developed by Tenova and Danieli

- EOR:

-

Enhanced Oil Recovery

- EUA:

-

European Union Allowances

- FINMET:

-

Fluidized bed iron ore reduction (VAI, Austria)

- FIOR:

-

Fluidized bed Iron Ore Reduction ESSO Research, USA

- FINEX:

-

A two-stage SR process incorporating fluid bed reduction and smelting

- HISARNA:

-

High-intensity iron making (SR process)

- HISMELT:

-

High-intensity smelting (SR process)

- HOGANAS:

-

Coal-based solid-state ironmaking process in tunnel kiln

- HYBRIT:

-

Hydrogen Breakthrough Ironmaking Technology

- HYL, MIDREX:

-

Direct reduction gas-based shaft furnace technologies

- IEAGHG:

-

International Energy Association Green House Gas Emission

- INMETCO:

-

International Metals Reclamation Company, Inc

- ITmk3:

-

Ironmaking Technology Marked three, third-generation ironmaking

- MDEA:

-

Methyl Di-Ethanol Amine

- MEA:

-

Mono-Ethanol Amine

- MTPA:

-

Million Tons Per Annum

- MXCOl:

-

Direct reduction with coal gasification

- NDC:

-

Nationally Determined Contributions

- PCI:

-

Pulverized Coal Injection

- RHF:

-

Rotary Hearth Furnace

- RK:

-

Rotary kiln

- SALCOS:

-

Salzgitter Low CO2 Steelmaking

- SR:

-

Smelting Reduction

- TGR-BF:

-

Top Gas Recycling Blast Furnace

- THM:

-

Metric Tons of Hot Metal

- TPA:

-

Metric tons per annum

- ULCOS:

-

Ultra-low CO2 Steelmaking

- WSA:

-

World Steel Association

References

IEA, Energy Technology Perspectives 2014, IEA, Paris. https://doi.org/10.1787/energy_tech-2014-en (2014).

IEA, Energy Technology Perspectives 2017, IEA, Paris. https://www.iea.org/reports/energy-technology-perspectives-2017 (2017).

European Commission, Climate Strategies and Targets. https://ec.europa.eu/clima/policies/strategies_en.

Croezen H, and Korteland M, A Long-Term View of CO2 Efficient Manufacturing in the European Region, Report Delft, CE Delft (2010).

IEA, CO2 Emissions from Fuel Combustion: Overview. https://stats2.digitalresources.jisc.ac.uk/metadata/IEA/co2/CO2%20Emissions_documentation_2020.pdf (2020).

IEA, Energy Technology Perspectives 2020, OECD Publishing, Paris. https://doi.org/10.1787/d07136f0-en (2020).

IEA, Key World Energy Statistics 2020, IEA, Paris. https://www.iea.org/reports/key-world-energy-statistics-2020 (2020).

Holappa L, Metals 10 (2020) 1117. https://doi.org/10.3390/met10091117.

UNEP Emissions Gap Report, Chapter 3. https://reliefweb.int/sites/reliefweb.int/files/resources/EGR2018_FullReport_EN.pdf (2018).

Pei M, Petäjäniemi M, Regnell A, and Wijk O, Metals 10 (2020) 1. https://doi.org/10.3390/met10070972.

UNFCC, United Nations Framework Convention on Climate Change. https://en.wikipedia.org/wiki/United_Nations_Framework_Convention_on_Climate_Change.

Naito M, Takeda K, and Matsui Y, ISIJ Int 55 (2015) 7.

Peacy J G, and Davenport W G, The Iron Blast Furnace: Theory and Practice, Pergamon Press, Oxford (1979), p. 251.

Biswas A K, Principles of Blast Furnace Ironmaking, SBA Publication, Kolkata (1984), p. 528.

Sahu R K, Roy S K, and Sen P K, Steel Res Int 86 (2015) 502.

Roy, G G, EEPC, September 2020, The Magic of Iron Making. https://www.eepcindia.org/eepc-magazine/magazine.aspx?id=MAZ0210202016442159532&magazine=September-2020.

Meijer K, Denys M, Lasar J, Birat J-P, Still, G, and Overmaat, B, Ironmak Steelmak 36 (2009) 249. https://doi.org/10.1179/174328109X439298.

Technologies Customized List, 2017. https://www.jisf.or.jp/en/activity/climate/Technologies/documents/TechnologiesCustomizedListIndiav3.pdf.

Mahanta B K, Sarkar S, Sen, P K, and Chakraborti N, Can Metall Q (2021). https://doi.org/10.1080/00084433.2021.2016344.

Nogami H, Kashiwaya Y, and Yamada D, ISIJ Int 58 (2012) 1523.

Yilmaz C, Wendelstorf J, and Turek T, J Clean Prod 154 (2017) 488. 1016/j.jclepro.2017.03.162.

Mousa E, Wang C, Riesbeck J, and Larsson M, Renew Sustain Energy Rev 65 (2016) 1247.

Norgate T, Haque N, Somerville M, and Jahanshahi S, ISIJ Int 52 (2012) 1472.

Suopajärvi H, Umeki K, Mousa E, Hedayati A, Romar H, Kemppainen A, Wang C, Phounglamcheik A, Tuomikoski S, Norberg N, and Andefors A, Appl Energy 213 (2018) 384.

Norgate T, and Langberg D, ISIJ Int 49 (2009) 587.

Feliciano-Bruzual C, and Mathews J A, Rev Metal 49 (2013) 458. https://doi.org/10.3989/revmetalm.1331.

Chatterjee A, Sponge Iron Production by Direct Reduction of Iron Oxide, PHI, New Delhi (2012).

Kekkonen M, and Holappa L E, Comparison of different coal based direct reduction processes, Report, Helsinki University of Technology, TKK-MK-99 (2000).

Fastmet Process. https://www.kobelco.co.jp/english/products/ironunit/fastmet/. Accessed January 2021.

Kumar B, Mishra S, Roy G G, and Sen P K, Steel Res Int 88 (2017) 1. https://doi.org/10.1002/srin.201600265.

Mishra S, and Roy G G, Metall Mater Trans B 47B (2016) 2347.

Kumar, B, Roy, G G, and Sen, P K, Energy Clim Change 1 (2020) 100016. https//doi.org/https://doi.org/10.1016/j-eqycc.2020.100016.

Kumar B, Roy G G, and Sen P K, Int J Exergy 36 (2021) 280. https://doi.org/10.1504/IJEX.2021.118721.

Cheeley R, and Marcus L, Coal Gasification Solution for Indian Ironmaking, Midrex Technologies, Inc. http://www.midrex.com/wp-content/uploads/Midrex_Paper_Jan_2010_Kolkata_Conference.pdf (2010).

Personal discussions and estimations with industry experts Shri A.C.R. Das.

Energiron DRI Technology by Tenova and Danieli. https://www.tenova.com/fileadmin/user_upload/tenova_products/steel_making_direct_and_pre_reduction_technologies/energiron_book_2014.pdf.

Mukhopadhyay A, and Ometto M, Energy Saving and CO2 reduction in Energiron DRI Production, 6th International Congress on the Science and Technology of Ironmaking – ICSTI, 42nd International Meeting on Ironmaking and 13th International Symposium on Iron Ore, October 14th to 18th, 2012, Rio de Janeiro, RJ, Brazil.

Sarkaria D, Case Study: Al Reyadah CCUS Project, Abu Dhabi Carbon Capture Company, Panel 2: Carbon Capture Process: Lessons Learned in Project Start-Up, United Arab Emirates 2nd May 2017. https://www.cslforum.org/cslf/sites/default/files/documents/AbuDhabi2017/AbuDhabi17-TW-Sakaria-Session2.pdf (2017).

DIRECT FROM MIDREX, “Ultra low CO2 steel making, transitioning to the hydrogen economy”, First Quarter 2020, Published in 2020 by Midrex Technologies. https://www.midrex.com/wp-content/uploads/Midrex-2020-DFM1QTR-Final.pdf (2020).

Arcelor Mittal, Climate Action Report 2, 2021. https://constructalia.arcelormittal.com/files/Climate_Action_Report_2_July_2021--94aa5d83ef86cd03ec059ef8d1728966.pdf.

Chatterjee A, Hot Metal Production by Smelting Reduction of Iron Oxide, PHI, ND (2010).

Technology Factsheet, Hisarna with CCUS. https://www.tatasteeleurope.com/static_files/Downloads/Corporate/About%20us/hisarna%20factsheet.pdf.

Meijer K, Zeilstra C, Teerhuis C, Ouwehand M, and van der Stel J, Trans Ind Inst Metals 66 (2013) 475.

Tata Steel and TNO, 2018, HIsarna: Demonstrating Low CO2 Ironmaking at Pilot Scale. https://www.co2-cato.org/cato-download/5540/20181211_122258_14_2018.12.04_CATO-meets-the-projects_vanderStel.

Danieli and Tenova, 2012, The New Generation of Direct Reduction Technology and Steelmaking Integration. https://www.energiron.com/wp-content/uploads/2019/05/ENERGIRON-DR-Technology-Overview.pdf.

Sarkar S, Bhattacharya R, Roy G G, and Sen P K, Steel Res Int 87 (2017) 1. https://doi.org/10.1002/srin.201700248.

Birat J P, Steel sectoral report, Contribution to the UNIDO roadmap on CCS - fifth draft. https://www.globalccsinstitute.com/archive/hub/publications/15671/global-technology-roadmap-ccs-industry-steel-sectoral-report.pdf (2010).

IEA Environmental Projects Ltd. (IEAGHG) Iron and Steel CCS Study, 2013, Techno economics Integrated Steel Mill, Report 2013/04, July 2013. https://ieaghg.org/publications/technical-reports/reports-list/9-technical-reports/1001-2013-04-iron-and-steel-ccs-study-techno-economics-integrated-steel-mill.

Farla J C M, Hendriks C A, and Blok K, Clim Change 29 (1995) 439. https://doi.org/https://doi.org/10.1007/BF01092428.

Gielen D, Energy Convers Manag 44 (2003) 1027.

Ho M, Bustamantea A, and Wiley D E, Int J Greenh Gas Control 19 (2013) 145.

Tsupari E, Kärkia J, Arastoa A, and Pisilä E, Int J Greenh Gas Control 16 (2013) 278.

Arasto A, Tsuparia E, Kärkia J, Erkki P, and Sorsamäkia L, Int J Greenh Gas Control 16 (2013) 271.

Arasto A, Tsuparia E, Kärkia J, Sihvonenb M, and Liljabet J, Energy Procedia 37 (2013) 7117.

Maiti A, Bhattacharya S, Bose S, Chatterjee S, and Mukherjee A, Evaluation of Techno-Economic Viability of Carbon Capture Utilization and Storage (CCU&S) With Carbon Credits for Steel Plants, AISTech 2019, Proceedings of the Iron & Steel Technology Conference 6–9 May 2019, Pittsburgh, PA, USA. 10.1000.377.010.

Arcelor Mittal Report. http://www.steelanol.eu/en. Accessed June 2021.

Wich T, Lueke W, Deerberg G, and Oles M, Front Energy Res 7 (2020) 1. https://doi.org/https://doi.org/10.3389/fenrg.2019.00162.

Gough C, and Upham P, Biomass energy with carbon capture and storage (BECCS): a review. Working Paper 147, Tyndall Centre for Climate Change Research. http://www.tyndall.ac.uk/publications/working_papers/working_papers.shtml (2010).

Rootzén J, Kjärstad J, Johnsson F, and Karlsson H, International Conference on Negative CO2 Emissions, May 22–24, 2018, Göteborg, Sweden. https://www.researchgate.net/publication/329143960_Deployment_of_BECCS_in_basic_industry-a_Swedish_case_study (2018).

IEA, Net Zero by 2050, IEA, Paris. https://www.iea.org/reports/net-zero-by-2050 (2021).

Gielen D, Saygin D, Taibi E, and Birat J-P, J Ind Ecol 24 (2020) 1113.

Proost J, Int J Hydrog Energy 45 (2020) 17067.

Zapantis A, Report on “Blue Hydrogen” Global CCS Institute. https://www.globalccsinstitute.com/wp-content/uploads/2021/04/Circular-Carbon-Economy-series-Blue-Hydrogen.pdf (2021).

World Steel Association, World Steel in Figures. https://www.worldsteel.org/en/dam/jcr:976723ed-74b3-47b4-92f6-81b6a452b86e/World%2520Steel%2520in%2520Figures%25202021.pdf (2021).

World Steel Association, Factsheets, Scrap Use in Steel Industry. https://www.worldsteel.org/publications/fact-sheets.html (2021).

World Steel Association, Raw Materials, In Factsheet: Steel and Raw Materials. https://www.worldsteel.org/steel-by-topic/raw-materials.html. Accessed June 2021 (2021).

Sahoo M, Sarkar S, Das A C R, Roy G G, and Sen P K, Steel Res Int 90 (2019) 1.

Amato A, Brimacombe L, and Howard N, Ironmak Steelmak 23 (1996) 236.

Toktarova A, Karlsson I, Rootzén J, Göransson L, Odenberger M, and Johnsson F, Energies 13 (2020) 3840. https://doi.org/10.3390/en13153840.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sen, P.K., Roy, G.G. Climate Change and Emission Reduction Pathways for a Large Capacity Coal-Based Steel Sector: Implementation Issues. Trans Indian Inst Met 75, 2453–2464 (2022). https://doi.org/10.1007/s12666-022-02622-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02622-5