Abstract

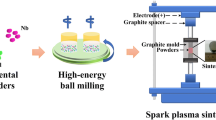

In this paper, the Ti25Zr25Ni25Co10Cu15 high entropy alloy has been investigated. A novel approach to manufacture high-temperature shape memory alloys is proposed. A fundamental possibility to obtain compact samples by powder bed fusion using a laser beam (PBF-LB) from Ti25Zr25Ni25Co10Cu15 powder obtained by mechanical alloying and plasma spheroidization is shown. During PBF-LB, a mixed structure is formed. It consists of B2-TiNi-type austenite with Laves phases and zirconium oxides. The average grain size is around 5 μm. The hardness of the alloy produced is more than 600 HV and significantly exceeds that of the alloy produced by conventional techniques. The ultimate compressive strength and the compressive yield strength of the samples are 640 MPa, and 600 MPa, respectively, meaning the synthesized samples are significantly inferior to the alloys produced by conventional smelting technologies. However, the ductility of 1.3% is comparable to that of similar alloys and indicates potential prospects of PBF-LB to manufacture Ti–Zr–Ni–Co–Cu HEAs.

Similar content being viewed by others

References

Cantor B, Chang I T H, Knight P, and Vincent A J B, Mater Sci Eng A 375–377 (2004) 213. https://doi.org/10.1016/j.msea.2003.10.257.

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, and Chang S Y, Adv Eng Mater 6 (2004) 299. https://doi.org/10.1002/adem.200300567.

Miracle D B, Miller J D, Senkov O N, Woodward C, Uchic M D, and Tiley J, Entropy 16 (2014) 494. https://doi.org/10.3390/e16010494.

Praveen S, and Kim H S, Adv Eng Mater 20 (2018) 1. https://doi.org/10.1002/adem.201700645.

Lee J I, Tsuchiya K, Tasaki W, Oh H S, Sawaguchi T, Murakami H, Hiroto T, Matsushita Y, and Park E S, Sci Rep 9 (2019) 1. https://doi.org/10.1038/s41598-019-49529-8.

Firstov G, Koval Y, van Humbeeck J, Timoshevskii A, Kosorukova T, and Verhovlyuk P, Mater Sci Found 81–82 (2015) 207. https://doi.org/10.4028/www.scientific.net/msfo.81-82.207.

Chen C-H, and Chen Y-J, Scr Mater 162 (2019) 185. https://doi.org/10.1016/j.scriptamat.2018.11.023.

Chen C H, Chen Y J, and Shen J J, Met Mater Int 50 (2019) 617. https://doi.org/10.1007/s12540-019-00383-3.

Aksoy C B, Canadinc D, and Yagci M B, Mater Chem Phys 236 (2019) 121802. https://doi.org/10.1016/j.matchemphys.2019.121802.

Hong S H, Kim J T, Park H J, Kim Y S, Suh J Y, Na Y S, Lim K R, Shim C H, Park J M, and Kim K B, J Alloys Compd 692 (2017) 77. https://doi.org/10.1016/j.jallcom.2016.09.023.

Firstov G S, Visn Nac Acad Nauk Ukrai’ni 06 (2018) 19. https://doi.org/10.15407/visn2018.06.019.

Ntouanoglou K, Stavropoulos P, and Mourtzis D, Procedia Manuf 18 (2018) 120. https://doi.org/10.1016/j.promfg.2018.11.016.

Farber E, Zhu J N, Popovich A, and Popovich V, Mater Today Proc 30 (2019) 761. https://doi.org/10.1016/j.matpr.2020.01.563.

Yamamoto T, Kato H, Murakami Y, Kimura H, and Inoue A, Acta Mater 56 (2008) 5927. https://doi.org/10.1016/j.actamat.2008.08.003.

Kim A, Makhmutov T, Razumov N, Silin A, Popovich A, Zhu J N, and Popovich V, Mater Today Proc 30 (2019) 679. https://doi.org/10.1016/j.matpr.2020.01.521.

Makhmutov T, Razumov N, Kim A, Ozerskoy A, Mazeeva A, and Popovich A, Met Mater Int 27 (2020) 50. https://doi.org/10.1007/s12540-020-00747-0.

Saedi S, Moghaddam N S, Amerinatanzi A, Elahinia M, and Karaca H E, Acta Mater 144 (2018) 552. https://doi.org/10.1016/j.actamat.2017.10.072.

Chen G, Zhao S Y, Tan P, Yin J, Zhou Q, Ge Y, Li Z F, Wang J, Tang H P, and Cao P, Trans Nonferrous Met Soc China (English Ed) 27 (2017) 2647. https://doi.org/10.1016/S1003-6326(17)60293-0.

Kim Y-W, Chung Y-S, Choi E-S, Nam T-H, and Im Y-M, J Korea Foundry Soc 31 (2011) 26. https://doi.org/10.7777/jkfs.2011.31.1.026.

Razumov N G, Makhmutov T Y, Kim A, Goncharov I S, Ozerskoi N E, Silin A O, and Mazeeva A K, and Popovich AA, Metallogr Microstruct Anal 10 (2021) 474. https://doi.org/10.1007/s13632-021-00770-6.

Persson K, TiNi mp-571 (2016). https://doi.org/10.17188/1276044.

Acknowledgements

This research was carried out with the support of the State contract # H.4щ.241.09.20.1081 dated June 4, 2020 “Development and material science substantiation of the design of materials and products based on shape memory alloys with a controlled structure and piezoelectric ceramics using additive 4D technologies. Stage of 2020” (IGK 17706413348200001110).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Razumov, N.G., Makhmutov, T.Y., Kim, A. et al. Structure and Properties of Ti–Zr–Ni–Co–Cu High-Entropy Alloy After Powder Bed Fusion of Powders Produced by Mechanical Alloying and Plasma Spheroidization. Trans Indian Inst Met 75, 2529–2538 (2022). https://doi.org/10.1007/s12666-022-02616-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02616-3