Abstract

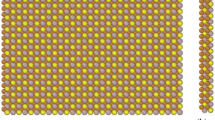

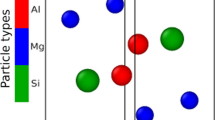

The creep behavior of an intermetallic compound plays a decisive role over the creep characteristics of various intermetallic alloys through the diffusion behavior of various elements which leads to tailor its creep characteristics. In this study, the creep behavior (in compression mode) of monolithic titanium aluminide (Ti3Al) alloy has been analyzed using molecular dynamics simulation under varying grain size (2.2 nm, 3.1 nm and 4.2 nm), pressure (1.5 GPa, 2 GPa and 2.5 GPa) and temperature (500 K and 700 K). Through the above analysis, it is found that the grain size of titanium aluminide alloy leads to invoke adverse effect over the creep characteristics followed by the temperature and the pressure. Furthermore, it is stated that the vacancy and lattice diffusion behavior under the lowermost and the higher temperature plays a dominant role over the creep mechanics of titanium aluminide alloy, owing to the dominant diffusion behavior of titanium and aluminum atoms.

Similar content being viewed by others

References

Dong L, Li Y, Devanathan R, and Gao F, RSC Adv 6 (2016) 41410.

Wu B, Heidelberg A, Boland J J, Sader E J, and Li S, Nano Lett 6 (2006) 468.

Yamakov V, Wolf D, Phillpot S, and Gleiter H, Acta Mater 50 (2002) 61.

Nagaraj M, and Ravisankar B, Materials Research Express (2018).

Keblinski P, Wolf D, and Gleiter H, Interface Sci 6 (1998) 205.

Nabarro F R N, Proc Conf Strength Solids 75 (1948).

Herring C, J Appl Phys 21 (1950) 437.

Coble R L, J Appl Phys 34 (1963) 1679.

Millett P C, Desai T, Yamakov V, and Wolf D, Acta Mater 56 (2008) 3688.

Kerry K, Winstone M R, Mater Sci Eng 192–193 (1995) 856.

Worth B D, Jones J W, and Allison J E, Metall Mater Trans A 26 (1995) 2961.

Abdallah Z, Whittaker M T, and Bache M R, Intermetallics 38 (2013) 55

Wang S, Huang L J, Geng L, Scarpa F, Jiao Y, and Peng H X, Sci Rep 7 40823.

Hayes R W, London B, Acta Metallurgica et Materialia 40 (1992) 2167.

Yu W, Hou S, Yang Z, Zhang J, and Lang S, Metals 10 (2020) 1190.

Harrison W, Abdallah Z, and Whittaker M, Materials 7 (2014) 2194.

Sahay S K, Singh S K, Goswami B, and Ray A K, High Temp Mater Process 24 (2005) 323.

Chen Y, Wang J, Feng Y, Zhao G, Jian X, Yang L, and Xu J, Mater Sci Eng: A 802 (2021) 140450.

Hamzah E, Kanniah M, and Harun M, Mater Manuf Process 22 (2007) 793.

Deevi S, Zhang W J, Liu C T, and Reddy B V, MRS Online Proc Libr Arch 646 (2001) 121.

Meraj M, Pal S, J Mol Model 23 (2017) 309.

Stukowski A, Model Simul Mater Sci Eng 18 (2009) 015012.

Zope R R, Mishin Y, Phys Rev B. 2668 (2003) 024102.

Meyers M A, Mishra A, and Benson D J, Prog Mater Sci 51 (2006) 427.

Nie K, Wu W P, Zhang X L, and Yang S M, J Mater Sci 52 (2017) 2180.

Desai T G, Millett P C, and Wolf D, Acta Mater 56 (2008) 4489.

Pal S, Meraj M, and Deng C, Comput Mater Sci 126 (2017) 382.

Srinivas S, Satyanarayana D V V, and Pandey M C, Trans Indian Inst Metal 49 (1996) 625.

Caillard D, Martin J L, Therm Act Mech Crystal Plast 8 (2003) 1.

Swygenhoven H V, Grain Bound Dislocat Sci 296 (2002) 66.

Schiotz J, Tolla F D D, and Jacobsen K W, Nature 391 (1998) 561.

Yip S, Nature 391 532 (1998).

Schiotz J, Jacobson K W, Science 301 (2003) 1357.

Yamakov V, Wolf D, Phillpot S R, Mukherjee A K, and Gleiter H, Nat Mater 3 (2004) 4.

Sun J, He L, Lo Y C, Xu T, Bi H, Sun L, Zhang Z, Mao S X, and Li J, Nat Mater 13 (2014) 1007.

Lu Y, Song J, Huang J Y, and Lou J, Adv Funct Mater 21 (2011) 3982.

Swygenhoven H V, Derlet P M, and Hasnaoui A, Phys Rev B 66 (2002) 024101.

Wolf D, Yamakov V, Phillpot S R, Mukherjee A, Gleiter H, Acta Mater 53 (2005) 1.

Swygenhoven H V, Derlet P M, Frøseth A G, Nat Mater 3 (2004) 399.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gowthaman, S., Jagadeesha, T. & Dhinakaran, V. Comparative Study on the Effect of Temperature, Pressure and Grain Size on the Creep Behavior of Monolithic Titanium Aluminide Alloy through Molecular Dynamics Simulation. Trans Indian Inst Met 75, 149–159 (2022). https://doi.org/10.1007/s12666-021-02410-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02410-7