Abstract

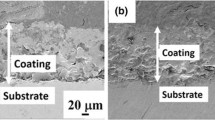

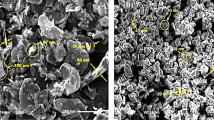

We aim to understand the tribological properties of graphene nanoplatelets (GNPs) reinforced hydroxyapatite (HA) composite coating synthesized using plasma spray on Ti alloy substrate (Ti-6Al-4 V). A significant reduction of 83% in wear volume loss is observed on addition of 2 wt. % GNPs in HA as compared to bare HA coating, respectively. Similarly, coefficient of friction (COF) shows the relative reduction of 70% is HA-2 wt. % GNP coating. Post-wear analysis by Raman spectroscopy confirms the retention of GNPs with the enlarged defect over the worn surface. FE-SEM investigation of worn surface shows the strengthening mechanism such as GNP bridging, GNP pull-out which could be attributed to enhanced wear resistance of the coating. GNPs induced lubrication has been observed as the prime reason for lower COF of the worn surface.

Similar content being viewed by others

References

Morks M F, J Mech Behav Biomed Mater 1 (2008) 105.

Palanivelu R, Kumar A R, Appl Surf Sci315 (2014) 372.

Palanivelu R, Kalainathan S, Kumar A R, Ceram Int40 (2014) 7745.

Morks M F, Fahim N F, Kobayashi A, Appl Surf Sci255 (2008) 3426.

Luo D B, Fridrici V, Kapsa P, Surface Coat Technol 204 (2010) 1259.

Singh A, Singh G, Chawla V, J Mech Behav Biomed Mater 85 (2018) 20.

Yugeswaran S, Yoganand C P, Kobayashia A, Paraskevopoulos K M, Subramanian B, J Mech Behav Biomed Mater 9 (2012) 22.

Balani K, Chen Y, Harimkar S P, Dahotre N B, Agarwal A, ActaBiomater 3 (2007) 944.

Hongqing L, Xie Y, Kai L, Liping H, Shansong H, Bizeng Z, Xuebin Z, Ceram Int40 (2014) 12821.

Priyadershini S, AsiqRahman O S, Pandey K K, Keshri A K, Ceram Int 45 (2019) 5768.

Liu H, Xi P, Xie G, Shi Y, Hou F, Huang L, Chen F, Zeng Z, Shao C, Wang J, J Phys Chem C 116 (2012) 3334.

Pandey K K, Singh S, Choudhary S, Zhang C, Agarwal A, Li L H, Chen Y, Keshri A K, Ceram Int 47 (2021) 7.

Mukherjee B, Rahman O S A, Aminul I, Sribalaji M, Keshri A K, J Alloy Compd 727 (2017) 658.

Lahiri D, Singh V, Keshri A K, Seal S, Agarwal A, Carbon 48 (2010) 3103.

Lahiri D, Singh V, Benaduce A P, Seal S, Kos L, Agarwal A, J Mech Behav Biomed Mater 4 (2011) 44.

Shen G, Fang F, Kang C, Nanotechnol Precision Eng 1 (2018) 107.

Singh S, Pandey K K, Rahman O S A, Haldar S, Lahiri D, Keshri A K, Mater Res Exp 7 (2020) 015415.

Ranjan S, Mukherjee B, Islam A, Pandey K K, Gupta R, Keshri A K, J Euro Ceram Soc 40 (2020) 660.

Shukla D K, Mukherjee B, Islam A, Keshri A K, Ceram Int 47 (2021) 17809.

Yugeswaran S, Kobayashi A, HikmetUcisik A, Subramanian B, Appl Surface Sci 347 (2015) 48.

Zhang C, Xu H, Geng X, Wang J, Xiao J, and Zhu P, J Thermal Spray Technol (2016).

Kontou A, Southby M, Spikes H A, Wear 390–391 (2017) 236.

Yazdani B, Xu F, Ahmad I, Sci Rep 23 (2015) 1.

Acknowledgements

Authors greatly acknowledge the financial and infrastructural facilities provided from Indian Institute of Technology, Patna, Bihar.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, S., Sharma, S. & Keshri, A.K. Tribological Behaviour of Plasma-Sprayed Graphene Nanoplatelets Reinforced Hydroxyapatite Nanocomposite Coating. Trans Indian Inst Met 74, 2901–2907 (2021). https://doi.org/10.1007/s12666-021-02367-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02367-7