Abstract

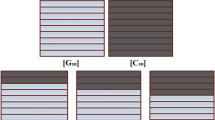

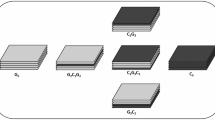

Natural fiber-reinforced polymer (NFRP) composites are biodegradable materials than synthetic fiber such as glass and carbon fiber reinforced polymer composites. However, due to the lower mechanical properties of NFRP composites, application in structural components is limited. Therefore, the present investigation focuses on the effect of carbon and glass fiber hybridization with flax and Kenaf fiber on tribo-mechanical properties of the hybrid composites. Four types of hybrid composites (C2F3C2, C2K3C2, G2F3G2 and G2K3G2) and plain glass, carbon, flax and kenaf fiber reinforced polymer composites are fabricated by hand lay-up method. The results reveal that flax fiber hybridization with carbon fiber (C2F3C2) gives the best hybrid effect and improves its flexural strength (364.4 ± 15.0 MPa), modulus (24.7 ± 1.4GPa), and Izod impact strength (26.5 ± 2.4 kJ/m2). However, Kenaf fiber hybridization with glass fiber (G2K3G2) gives optimum flexural strength (335.6 ± 33.2 MPa), modulus (17.2 ± 0.9GPa), and Izod impact strength (80.2 ± 16.0 kJ/m2). Kenaf fiber reinforced polymer hybrid composites (G2K3G2) show the lowest abrasive specific wear rate (21.9 ± 0.9mm3/Nm) compared to other hybrid composites. Furthermore, the fractography analysis of hybrid composites is carried out using scanning electron microscopy to make possible structure–property co-relationship.

Similar content being viewed by others

References

D. K. Jesthi, P. Mandal, A. K. Rout, and R. K. Nayak, Procedia Manufacturing 20, 536 (2018).

D. K. Jesthi and R. K. Nayak, Composites Part B: Engineering 168, 467 (2019).

D. K. Jesthi, A. Nayak, S. S. Mohanty, A. K. Rout, and R. K. Nayak, IOP Conf. Ser.: Mater. Sci. Eng. 377, 012157 (2018).

A. Nayak, D. Kumar Jesthi, B. Chandra Routara, D. Das, and R. Kumar Nayak, Materials Today: Proceedings 5, 19828 (2018).

D. K. Jesthi and R. K. Nayak, Mater. Res. Express 7, 015106 (2020).

S. Khandai, R. K. Nayak, A. Kumar, D. Das, and R. Kumar, Materials Today: Proceedings 18, 3835 (2019).

F. Ning, W. Cong, J. Qiu, J. Wei, and S. Wang, Composites Part B: Engineering 80, 369 (2015).

C. Y. Lee, J.-H. Bae, T.-Y. Kim, S.-H. Chang, and S. Y. Kim, Composites Part A: Applied Science and Manufacturing 75, 11 (2015).

A. P. Cysne Barbosa, A. P. P. Fulco, E. S.S. Guerra, F. K. Arakaki, M. Tosatto, M. C. B. Costa, and J. D. D. Melo, Composites Part B: Engineering 110, 298 (2017).

S. Swarup Mohanty, A. Kumar Rout, D. Kumar Jesthi, B. Chandra Routara, and R. Kumar Nayak, Materials Today: Proceedings 5, 19854 (2018).

S. Nayak, R.K.Nayak, I. Panigrahi, and A. K. Sahoo, Materials Today: Proceedings 18, 4042 (2019).

R. K. Nayak, A. Dash, and B. C. Ray, Procedia Materials Science 6, 1359 (2014).

J. P. Dhal and S. C. Mishra, Journal of Materials 2013, (2012).

K. Singh, D. Das, R. K. Nayak, S. Khandai, R. Kumar, and B. C. Routara, Materials Today: Proceedings 26, 2094 (2020).

N. Saba, M. T. Paridah, and M. Jawaid, Construction and Building Materials 76, 87 (2015).

V. Fiore, G. Di Bella, and A. Valenza, Composites Part B: Engineering 68, 14 (2015).

M. Cihan, A. J. Sobey, and J. I. R. Blake, Composites Science and Technology 172, 36 (2019).

. Yu and C. Zhou, Composite Structures 188, 1 (2018).

C. M. Meenakshi and A. Krishnamoorthy, in Advanced Manufacturing and Materials Science, edited by K. Antony and J. P. Davim (Springer International Publishing, Cham, 2018), pp. 93–101.

A. Praveen Kumar and M. Nalla Mohamed, Journal of Industrial Textiles 47, 2050 (2018).

D. Sivakumar, L. F. Ng, S. M. Lau, and K. T. Lim, J Polym Environ 26, 499 (2018).

K. Subramaniam, S. D. Malingam, N. L. Feng, and O. Bapokutty, Polymer Composites 40, 568 (2019).

S. D. Malingam, L. F. Ng, K. H. Chan, K. Subramaniam, M. Z. Selamat, and K. A. Zakaria, Mater. Res. Express 5, 095304 (2018).

M. Hafizal Hamidon, M. T. H. Sultan, and A. Hamdan Ariffin, in Failure Analysis in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, edited by M. Jawaid, M. Thariq, and N. Saba (Woodhead Publishing, 2019), pp. 133–156.

Procedia Engineering 41, 1654 (2012).

M. Arulkumar, K. S. Rajeshwaran, and G. S. Sathish, Mechanics, Materials Science & Engineering MMSE Journal. Open Access 9, (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saroj, S., Nayak, R.K. Improvement of Mechanical and Wear Resistance of Natural Fiber Reinforced Polymer Composites Through Synthetic Fiber (Glass/Carbon) Hybridization. Trans Indian Inst Met 74, 2651–2658 (2021). https://doi.org/10.1007/s12666-021-02347-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02347-x