Abstract

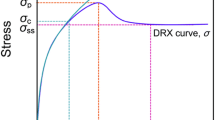

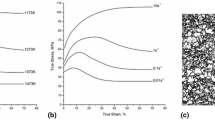

The stress–strain curves of a bainite steel have been measured with hot compression experiments at temperatures of 1173, 1273, 1373, 1473 K and strain rates of 0.01, 0.1, 1, 10 s−1 on a thermo-mechanical simulator (Gleeble-1500). The processing maps, activation energy maps, and the overlap regions of dynamic recrystallization zones and flow stability domains have been obtained by utilizing the stress–strain data experimented. The feasible process windows have been determined according to a new criterion that these windows are in the overlap regions where the activation energy isoline is the sparsest with its variation no more than 1%. Moreover, the optimum temperature and strain rate for a given strain have been ascertained by the largest power dissipation efficiency within the feasible process windows.

Similar content being viewed by others

References

Ning Y, Yao Z, Lei Y, Guo H, and Fu M W, Mater Charact 62 (2011) 887.

Sun C-c , Liu K, Wang Z-h, Li S-b, Du X, and Du W-b, Trans Nonferrous Met Soc China 26 (2016) 3123.

Liu Y, Geng C, Lin Q, Xiao Y, Xu J, and Kang W, J Alloys and Compd 713 (2017) 212.

Zhou Z, Fan Q, Xia Z, Hao A, Yang W, Ji W, and Cao H, J Mater Sci Technol 33 (2017) 637.

Chen L-l, Luo R, Yang Y-t, Peng C-T, Jie Zhang XG, Song K-y, and Cheng X-n, Trans Indian Ins Met 72 (2019) 2997.

Bodunrin M O, Chown L H, van der Merwe J W, and Alaneme K K, Int J Mater Form 12 (2019) 857.

Zhang J, Di H, Wang H, Mao K, Ma T, and Cao Y, J Mater Sci 47 (2012) 4000.

Monmeni A, and Dehghani K, Mater Sci Eng A 527 (2010) 5467.

Zhang D, Yang X, Sun H, Li Y, Wang J, Zhang Z, Ye Y, and Sakai T, Mater Sci Eng A 640 (2015) 51.

Shu X, Lu S, Wang K, and Li G, Met Mater Int 4 (2015) 726.

Shi C, Mao W, and Chen X, Mater Sci Eng A 571 (2013) 83.

Asgharzadeh H, Simchi A, and Kim H, J Mater Sci 46 (2011) 4994.

Wang S, Hou L G, Luo J R, Zhang J S, and Zhuang L Z, J Mater Process Tech 225 (2015) 110.

Sun Y, Cao Z, Wan Z, Hu L, Ye W, Li N, and Fan C, J Alloys and Compd 742 (2018) 356.

Xu W, Yang X, Jiang Z, and Wang Q, Int J Mater Form 7 (2014) 405.

Meng Q, Bai C, and Xu D, J Mater Sci Technol 34 (2018) 679.

Wen D-X, Lin Y C, Li H-B, Chen X-M, Deng J, and Li L-T, Mater Sci Eng A 591 (2014) 183.

Kil T-D, Lee J-M, and Moon Y-H, J Mater Process Tech 220 (2015) 224.

Zhou G, Ding H, Cao F-r, Han Y-b, and Zhang B-j, Trans Nonferrous Met Soc China 22 (2012) 1575.

Cui W F, Zhang S X, Jiang Y, Dong J, and Liu C M, Mater Sci Eng A 528 (2011) 6401.

Kong X, Lan L, Hu Z, Li B, and Sui T, J Mater Process Technol 217 (2015) 202.

Sung H K, Lee D H, Shin S Y, Lee S, Yoo J Y, and Hwang Y, Mater Sci Eng A 624 (2015) 14.

Li L, Ye B, Liu S, Hu S, and Li B, Mater Sci Eng A 636 (2015) 243.

Chen X-M, Lin Y C, Wen D-X, Zhang J-L, and He M, Mater Des 57 (2014) 568.

Li L, Ye B, Liu S, Hu S, and Liao H, J Mater Eng Perform 25 (2016) 4581.

Li L, Zheng L, Ye B, and Zeqiong T, Met Mater Int 24 (2018) 60.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, L., Wei, L. & Ye, B. Deformation Window and the Optimum Process Parameter Determination of a Bainite Steel Based on Processing Maps, Activation Energy Maps, and Dynamic Recrystallization Conditions. Trans Indian Inst Met 74, 2409–2415 (2021). https://doi.org/10.1007/s12666-021-02329-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02329-z