Abstract

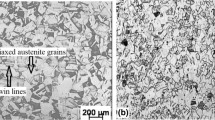

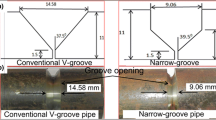

The pulsed current gas metal arc (PGMA) welding and shielded metal arc (SMA) welding with a narrow groove joint were used to weld the thick wall 304LN stainless steel pipe. The primary emphasis has been laid on the welding procedure by reducing the weld area with a narrow groove design. A constant heat input of 7.5 ± 0.5 kJ/cm was used to perform the narrow gap SMA and PGMA welding of austenitic stainless steel pipe. The PGMA welding was carried out at two different ϕ of 0.05 and 0.25 and groove width of 15 and 11 mm. The obtained results have shown that the narrow groove PGMA welds prepared at relatively lower Ω having 4–7% δ-ferrite content are comparatively less prone to solidification cracking than the SMA weld joint. The amount of porosity content was marginally increased in PGMA welds, whereas in the narrow groove SMA welds, the amount of porosity and inclusion content got increased by almost 30%. The narrow groove PGMA welds have significantly higher yield strength in both the longitudinal (363 MPa) and circumferential (466 MPa) directions than the SMA weld joints. Narrow groove PGMA welds have appreciably better Cv-impact toughness (126 J) and lateral expansion (2.5 mm) than that observed in SMA weld joint. The narrow groove PGMA weld (11 mm weld width) of various ϕ of 0.05 and 0.25 show widespread ductile fracture behavior with fine dimples and significantly minor porosity content than the SMA weld joints. The PGMA welds are comparatively less scattered in hardness across the weld and HAZ at both the Ω and ϕ levels.

Similar content being viewed by others

References

Shtrikman, M.M. and Grinin, V.V., The automatic narrow gap welding of high strength steels and titanium alloys, Welding Production, 1977, 24(1), 19–23.

Swada, S., Hori, K., Kawahara, M., Takao, M. and Asano,I., Application of narrow gap process Welding Journal, 1979, 59(9), 17–25.

Vornovitskii, L.V., Gelpern, S.A., Tureshskii, A.V., The manual narrow gap arc welding of non-rotating joints in pipelines, Welding Production, 1977, 24(6), 18–20.

Murugan, S., Rai, S.K., Kumar, P.V., Jayakumar, J., Baldev Raj, and Bose, M.S.C., Temperature distribution and residual stresses due to multipass welding in type 304 stainless steel and low carbon steel weld pads, Int. J. Pres. Ves. Pip, 2001, 78(4), 307–317.

Rajamurugan, G., Ghosh, P.K., Prabu, K. et al. Thermal and weld bead characteristics of bead-on-plate PGMA welding of dissimilar ASS bead on HSLA Plate. Trans Indian Inst Met. 2020, 74, 89–106. https://doi.org/10.1007/s12666-020-02106-4.

Siewert, T.A., McCowan, C.N. and Olson, D.L., Ferrite number prediction to 100 FN in stainless steel weld metal, Welding Journal, 1988, 67(1), 289s–298s

Shankar, V., Gill, T.P.S., Mannan, S.L. and Sundaresan, S., Solidification cracking in austenitic stainless steel welds, Sadhana, 2003b, 28(3/4), 359–382.

Joseph, A., Harwig, D., Farson, D. F. and Richardson, R., Measurement and calculation of arc power and heat transfer efficiency in pulsed gas metal arc welding, Science and Technology of Welding and Joining, 2003, 8(6), 400–406.

Ghosh, P.K. and Sharma, V., Weld bead chemistry and its characteristics in pulsed MIG welded Al-Zn-Mg alloy, Materials Transactions JIM, 1991, 32(2), 145–150.

Suban, M., Tusek, J. and Uran, M., Use of hydrogen in welding engineering in former times and today, Journal of Material Processing Technology, 2001, 119, 193–198.

Govindasamy, R., "Comparative studies on conventional groove SMA and GMA welds of dissimilar 304LN ASS and HSLA steels," SAE Technical Paper 2020-28-0405, 2020. https://doi.org/10.4271/2020-28-0405.

Koseki, T. and Flemings, M.C., Solidification of undercooled Fe–Cr–Ni alloys part II – microstructural evolution, Met.Mat.Tran A, 1996, 27A, 3226–3240.

Lippold, J.C. and Savage, W.F., Solidification of austenitic stainless steel weldments-Part III. The effect of solidification behaviour on hot cracking susceptibility, Welding Journal, 1986, 62, 204s–209s.

Rajamurugan, G., Ghosh, P.K., Prabu, K. et al. Dendrite Morphological Analysis on SMA, GMA, and PGMA Welding of Dissimilar 304LN Austenitic Stainless Steel and Micro-alloyed Steel. Trans Indian Inst Met. 2020, 73, 595–611. https://doi.org/10.1007/s12666-020-01871-6.

Tavassoli, A.A., Assessment of austenitic stainless steels, Fusion Engineering and Design, 1995, 29, 371–390.

Folkhard, E., Welding Metallurgy of Stainless Steels, Springer-Verlag, Wien 1984.

Padilha, A. F. and Rios, P.R., Decomposition of austenite in austenitic stainless steels, ISIJ International, 2002, 42(4), 325–337.

Rajamurugan, G., Dinesh, D. and Ramakrishnan, A., Comparative study on grain size and HAZ width of GMA and PGMA welds of dissimilar ASS and HSLA steel plates. Int J Mech Prod Eng Res Dev 2018, 8, 1641–1649.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kulkarni, S., Rajamurugan, G. & Ghosh, P.K. Prominence of Narrow Groove on Pulsed Current GMA and SMA Welding of Thick Wall Austenitic Stainless Steel Pipe. Trans Indian Inst Met 74, 2297–2312 (2021). https://doi.org/10.1007/s12666-021-02298-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02298-3