Abstract

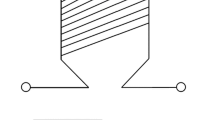

After running for about 59 000 h, the tubes at the intermediate mixing header of the furnace water wall leaked in an ultra-supercritical boiler. Preliminary analyses show that the primary crack may be initiated from two kinds of crack. One kind of crack is the dense transverse cracks in the external walls of the fireside, and the other one is the crack in adjacent H-shaped fin fillet weld. In order to figure out the initiation of the primary crack, the macroscopic morphology, chemical composition, microstructure, Vickers hardness and fracture morphology observation were conducted on the sample tube. The oriented dimples in the primary crack indicate that the crack propagates from the external side to the inner side. The erosive metal loss at fireside surfaces of tubes adjacent to the initial cracking shows significant differences. It is indicated that the primary crack is initiated from one side connected with the H-shape fin fillet weld crack. Based on comprehensive analyses of material quality of the sample tube and boiler operation data, it can be concluded that the wall temperature of water wall tubes changes with the frequent and large fluctuation of boiler load due to peak regulation operation, which is the root cause of fatigue cracking of H-shape fin fillet weld.

Similar content being viewed by others

References

James J. Dillon, Paul B. Desch, Tammy S. Lai, et al. Nalco Guide to Boiler Failure Analysis, Second Edition[M]. McGraw-Hil, in U.S.A, 2011.

Ji L, Zhi C, Liying T, et al. Microstructure investigation on S30432 steel used for heating surface tubes of a double reheat boiler[J]. Therm Power Gener. 2017; (8):72–76. (In Chinese).

Liu, S.W.,Wang, W.Z, et al. Failure analysis of the boiler water-wall tube[J]. Case Stud in Eng Failure Analy. 2017, 9: 35-39.

Duarte, C. A., Espejo, Edgar, et al. Failure analysis of the wall tubes of a water-tube boiler. Eng Failure Analy. 2017, 79: 704–713.

Jeff Henry, Gang Zhou, Ted Ward. Lessons from the past: materials-related issues in an ultra-supercritical boiler at Eddystone plant[J]. High Temp Technol, 2014, 24(4):249-258.

S. Srikanth, K. Gopalakrishna, S. K. Das, et al. Phosphate induced stress corrosion cracking in a water wall tube from a coal fired boiler[J]. Eng Failure Analy, 2003, 10(4):491-501.

Neal Hanke. Evaluation of a Failed Water Wall Boiler Tube[J]. J Failure Analy Prevent, 12(1):11–15.

Zheng, Xiang Feng, Jiang, Yun Jian, Xue, Rong Gang,et al. Failure Analysis and Welding Repair for Water Wall Tube Crack of Supercritical Boiler[J]. Adv Mater Res, 1004–1005:1410–1414.

ZHANG Guangcai, ZHOU Ke, LU Fen, et al. Discussions on deep peaking technology of coal-fired power plants [J].Therm Power Generat, 2017,(9):17–23. (In Chinese.)

Ding N , Duan J , Xue S , et al. Overall review of peaking power in China: Status quo, barriers and solutions[J]. RenewSustain Energy Rev, 2015, 42:503-516.

Ruppert, H. Barriers to Increased Flexibility of Thermal Power Plants. 2015,1–10. (https://www.researchgate.net/publication/309476773_Barriers_to_Increased_Flexibility_of_Thermal_Power_Plants)

FAN Zhidong, MA Yichao, ZHANG Zhibo, et al. Failure Analysis of Water Wall Tubes' Leakage in (Ultra) Super-critical Boiler. Hot Work Technol, 2017, 46(23): 254–258,253. (In Chinese)

ZHANG Jia-wei, ZHANG Zhong-hua, ZHANG Zhen-jie, et al. Reason Analysis and Process on Vertical Rising Rifled Tube Transverse Crack of Ultra-supercritical Boiler. Northeast Electric Power Technol, 2013, 34(10): 24–30. (In Chinese)

National standardization administration of China. Seamless steel tubes and pipes for high pressure boiler [S]. GB/T 5310, 2018.

YANG Jian-ju,ZHANG Dong-wen,FENG Yan-ting,et al.Preliminary analysis of ribben structure in high quality carbon steel [J].Therm Power Generat ,2009,(12):98–101. (In Chinese)

ZHONG Qun-peng, ZHAO Zi-hua. Fractography[M], Higher Education Press, in BeiJing, 2005: 149–153. (In Chinese)

Gu Y, Xu J, Chen D, et al. Overall review of peak shaving for coal-fired power units in China. Renew Sustain Energy Rev, 2016, 54:723-731.

Yadav S D, Sonderegger B, Sartory B, et al. Characterisation and quantification of cavities in 9Cr martensitic steel for power plants. Mater ence Technol, 2015, 31(5):554-564.

Kassner M E , Hayes T A . Creep cavitation in metals. Int J Plast, 2003, 19(10):1715-1748.

S. K. Dhua, Atul Saxena, B. K. Jha. Failure Analysis of Boiler Tubes Used in a Thermal Power Plant [J]. Trans Indian Inst Metals. 2016, 69(2):653–657.

Testing of metallic materials - Conversion of hardness values [S]. DIN 50150,1999.

Acknowledgement

This work was financially supported by the Science and Technology Project of China Huaneng Group [grant number HNKJ18-H45]. The authors are grateful for this support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fan, Z., Wang, Q., Niu, K. et al. Water Wall Tube Cracking in an Ultra-Supercritical Boiler Caused by Deep Peaking. Trans Indian Inst Met 75, 183–191 (2022). https://doi.org/10.1007/s12666-021-02243-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02243-4