Abstract

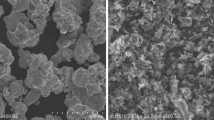

Warm forging of a (1%C–1.5%Cr) bearing steel at 760 and 800 °C could enable the achievement of a fully spheroidized microstructure comparable to that of the steel spheroidized by long-duration annealing treatment. The deformation-induced spheroidization gave higher hardness, strength, and toughness than the annealed steel. The deformation-induced grain structure and the finer dispersion of the residual carbides at the warm forging temperature promoted divorced eutectoid transformation when the steel was cooled below A1 temperature. A still higher temperature warm forging at 820 °C gave a partially spheroidized microstructure, with a significant fraction of pearlite colonies, resulting in inferior mechanical properties. The lower equilibrium carbide at higher warm forging temperature gave large islands of austenite devoid of carbides, which on cooling below A1 transformed to pearlite. The microstructure evolution and mechanical properties were examined at various stages of processing.

Similar content being viewed by others

References

Verhoeven J D and Gibson E D, Metall Mater Trans A 29 (1998) 1181

Zhu G H and Zheng G, Front Mater Sci China 2 (2008) 72

Qian D, Yang J, Mao H and Hua L, Int Conf Technol Plast-Procedia Eng 207 (2017) 1224

Huo Y, He T, Chen S and Wu R, JOM 70 (2018) 1112

Zhang S L, Sun X J and Dong H, Mater Sci Eng A 432 (2006) 324

Parusov V V, Dolzhenkov I I and Sukhomlin V I, Metal Sci Heat Treat 27 (1985) 402

Tao W U, Wang M Z, Gao Y W, Li X P, Zhao Y C and Zou Q, J Iron Steel Res Int 19 (2012) 60

Arruabarrena J, Uranga P, Lopez B and Rodriguez-Ibabe J M, Different routes for the development of ferrite pearlite microstructures suitable for spheroidization during soft annealing treatments, Materials Science and Technology (MS&T) 2014, October 12-16, (2014), Pittsburgh, Pennsylvania, USA, pp. 437–444

Han D X, Du L X, Zhang B and Misra R D, J Mater Sci 54 (2019) 2612

Erişir E, Bilir O G and Gezmişoğlu A E, IOP Conf Ser Mater Sci Eng 179 (2017) 012021

Lee S J and Clarke K D, Metall Mater Trans A 46 (2015) 3917

Walser B and Sherby O D, Metall Mater Trans A 10 (1979) 1461

Wray P J, Metall Mater Trans A 15 (1984) 2041

Pandit A S and Bhadeshia H K D H, Proc R Soc A 468 (2012) 2767

Mapelli C, Venturini R and Boniardi M, Scand J Metall 34 (2005) 192

Song W, Choi P P, Inden G, Prahl U, Raabe D and Bleck W, Metall Mater Trans A 45 (2014) 595

Luzginova N V, Zhao L and Sietsma J, Metall Mater Trans A 39 (2008) 513

Hauserov D, Dlouhy J and Kover M, Arch Metall Mater 62 (2017) 201

Zhao P and Boyd J D, Mater Sci Tech 23 (2007) 1186

Balachandran G, Menaka K and Ravichandar D, Trans IIM 72 (2019) 401

Karthick R, Balachandran G and Ravichandar D, Trans IIM 72 (2019) 411

Acknowledgements

The authors would like to thank their colleagues Mr. R. Gobinath, Mr. D. Balachander, Mr. P. Periyasamy, and Mr. S. Hemachandra Nalan for their technical support and assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vidhyasagar, M., Balachandran, G. Spheroidization of 100Cr6 Bearing Steel by Warm Forging. Trans Indian Inst Met 74, 767–774 (2021). https://doi.org/10.1007/s12666-021-02193-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02193-x