Abstract

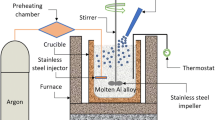

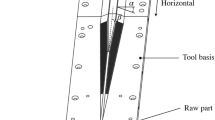

Metal matrix shafts are widely used in industries, and various research works are available for the characterization and applications of these components. These research works are limited to the conventional characterization of the material. In this paper, a novel characterization approach has been adopted, which determines the effect of reinforcements on the dynamic properties and residual stress of the Al 6061/Al2O3 shafts. Long and slender shafts were fabricated through a stir casting process. Grain structure was obtained through optical microscopy, and morphological evaluation of the composites was performed through scanning electron microscopy. In addition, X-ray diffraction patterns were analysed, and residual stress was calculated by X-ray residual stress measurement system μ-X360 Ver. 2.3.0.1. Tensile residual stress was observed for pure Al 6061 alloy shaft on the surface of shafts, whereas compressive residual stress was observed in the case of composite shafts. The magnitude of the compressive residual stress increased with the increased wt% of alumina in the Al 6061 matrix. The amplitudes of vibration were also reduced by the introduction of reinforcements in metal matrix composites.

Similar content being viewed by others

References

Sarmasti A B, Yazdanirad M, Khezrabad M N, and Karbalaie M, Mater Sci Technol 27 (2011) 1653.

Koczak M J, Khatri S C, Allison J E, and Bader M G, in Fundamentals of Metal-Matrix Composites, (eds) Suresh S, Mortensen A and Needleman A, Elsevier, Amsterdam (2013), p 297.

Rawal S, Jom. 53 (2001) 14.

Prasad S V, and Asthana R, Tribol Lett 17 (2004) 445.

Soltani S, Khosroshahi A R, Mousavian T R, and Jiang Z Y, Rare Met 36 (2017) 581.

Pazhouhanfar Y, and Eghbali B, Mater Sci Eng A 710 (2018) 172.

Miracle D B, Compos Sci Technol 65 (2005) 2526.

Ravi K R, Sreekumar V M, Pillai R M, Mahato C, Amaranathan K R, and Kumar R A, Mater Des 28 (2007) 871.

Sahu M K, and Sahu R K, Trans Indian Inst Met 70 (2017) 2563.

Singh S, Singh I, and Dvivedi A, Int J Cast Met Res 30 (2017) 356.

Sahu M K, and Sahu R K in Advanced Casting Technologies, (ed) Vijayaram T R, IntechOpen Press, London (2018), p 1076.

Chauhan H, Khan I, and Chauhan A, Int Res J Eng Technol 4 (2017) 2407.

Ahmed O, and Mohamed O, Synthesis and Characterization of Al6061/Al2O3 Metal Matrix Nanocomposites Fabricated by Stir-casting, PhD Thesis, Beni Suef University, Egypt (2019).

Pitchayyapillai G, Seenikannan P, Balasundar P, and Narayanasamy P, Trans Nonferrous Met Soc China 27 (2017) 2137.

Narayanasamy P, Selvakumar M, Ramkumar T, Mohanraj M, and Pillai G P, J Therm Anal Calorim 412 (2020) 1.

Pitchayyapillai G, Seenikannan P, Raja K, and Chandrasekaran K, Adv Mater Sci Eng 2016 (2016) 1.

Noyan I C, and Cohen J B, Measurement by Diffraction and Interpretation, Springer, New York (1987), p 75.

Ohya S, J Soc Mater Sci 10 (2005) 05.

Kondoh T, Goto T, Sasaki T, and Hirose Y, Adv X-ray Anal 43 (2000) 107.

Gelfi M, Bontempi E, Roberti R, and Depero L E, Acta Mater 52 (2004) 583.

Wang J S, Hsieh C C, Lai H H, Kuo C W, Wu P T Y, and Wu W, Mater Charact 99 (2015) 248.

Wang, B, and Qu S, IOP Conf Ser Mater Sci Eng 397 (2018) 012112.

Agarwal B D, Lifshitz J M, Lawrence J, and Broutman Fibre Sci Technol 7 (1974) 45.

Clegg W J, Acta Metall 36 (1988) 2141.

Wang Z, Chen T K, and Lloyd D J, Metall Trans A 24 (1993) 197.

Chatterjee S, Sur S G, Bandyopadhyay S, and Basumallick A, J Compos Mater 50 (2016) 2687.

Arsenault R J, and Taya M, Acta Metall 35 (1987) 651.

Jain A K, Rastogi V, and Agrawal A K, Proc Eng 144 (2016) 1451.

Tanaka K, Mech Eng Rev 6 (2019) 378.

Nguyen V, and Hwang P, Int J Mech Eng App 3 (2015) 22.

Valiev R Z, Islamgaliev R K, Kuzmina N F, Li Y, and Langdon T G, Scr Mater 40 (1998) 117.

Borbély A, Kenesei P, and Biermann H, Acta Mater 54 (2006) 2735.

Acknowledgements

This paper incorporates work carried out by the lead author at Design Centre, Department of Mechanical, Production, Industrial and Automobile Engineering, Delhi Technological University, Delhi, India. The authors would also like to acknowledge the SEM Central Facility at IIT Delhi for providing ZEISS EVO Series Scanning Electron Microscope EVO 50 to perform Scanning Electron Microscopy of composite samples. Grant for performing experimental work has been provided by TEQIP-III Project under “Academic Processes (1.3.2.5—Research and Development)”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, A., Rastogi, V. & Agrawal, A.K. Microstructural, Dynamic and Residual Stress Analysis of Metal Matrix Composite Shafts. Trans Indian Inst Met 73, 2995–3005 (2020). https://doi.org/10.1007/s12666-020-02101-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02101-9