Abstract

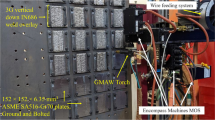

This paper aims to study the solidification structure of Ni-based superalloy class AWS ER NiCrMo-4 metallic coatings deposited by GMAW and gas metal arc welding-cold wire (GMAW-CW) processes with two heat input levels (0.9 and 0.6 kJ mm−1) on carbon steel plates. The metallurgical characterization of the coating’s interface was performed by scanning electron microscopy, optical microscopy, and electronic dispersion spectroscopy. Mechanical evaluation was carried out by Vickers hardness test. The results revealed that the welding conditions did not influence the solidification structure (planar, columnar, and equiaxed); however, molybdenum microsegregation to interdendritic region was observed. Cold wire addition by GMAW-CW process decreased the iron dilution on weld metal, but increased the partially mixed zone thickness and hardness values. The increase in heat input produced the opposite behavior to the cold wire feeding.

Similar content being viewed by others

References

Silva C C, Miranda E C, Motta M F, Miranda H C, and Farias J P, Soldagem & Inspeção 19 (2014) 4.

Frei J, Alexandrov B T, and Rethmeier M, Weld World 60 (2016).

Frei J, Alexandrov B T, and Rethmeier M, Weld World 62 (2018).

Dai T, and Lippold, J C, Weld J 96 (2017).

Dai T, Wheeling R A, Vaeth K H, and Lippold, J C, Weld World 14 (2019).

Garcia D N, Mechanical and Metallurgical Behavior of Steel Welded Joint ASTM A182 F22 Applied in the Offshore Industry, Ph.D. Thesis, Federal University of Uberlandia, Brazil (2018).

Sábio A D, Estudo da Viabilidade Operacional do Processo de Soldagem MAG com Alimentação Adicional de Arame Frio, Dissertation, Federal University of Pará, Brazil (2007).

Mota C A M, Nascimento A S, Garcia D N, Silva D A S, Teixeira F R, and Ferraresi V A. Soldagem & Inspeção 21 (2016) 4.

Silva H R, and Ferraresi V A, Wear 426 (2019).

Jorge V L, Scotti F M, Reis R P, and Scotti A, Int J Adv Manuf Technol 107 (2020).

Bentes Neto F M A, Switchback and Cold Wire GMAW-P Welding Applied to Aluminum Additive Manufacturing, Dissertation, Federal University of Pará, Brazil (2020).

Kou S, Welding Metallurgy, Wiley, New Jersey (2003) p 468.

Seppo L, Continuous Casting of Steel, Elsevier, England (2014) p 373.

Yang Y K, and Kou S, Weld J 86 (2007) a.

Yang Y K, and Kou S, Weld J 86 (2007) b.

Yang Y K, and Kou S, Weld J 86 (2007) c.

Chunming W, Lingyue C, Gaoyang M, Ping J, Xinyu S, and Youmin R, J Alloys Compd 726 (2017).

Dongjiang W, Bo C, Jun L, Dehua L, Guangyi M, and Zhenqiang Y, J Manuf Process 45 (2019).

Naffakh H, Shamanian M, and Ashrafizadeh F, J Mater Process Technol 209 (2009) 7.

Alexandrov B T, Lippold J C, Sowards J W, Hope A T, and Saltzmann D R, Weld World 57 (2012) 1.

Beaugrand V C M, Smith L S, Gittos M F, 28th International Conference on Ocean, Offshore and Arctic Engineering (2009).

Dodge M F, Dong H B, Milititski M, Barnett R P, and Gittos M F, 32 nd International Conference on Ocean, Offshore and Arctic Engineering (2013).

Mota C A M, Nascimento A S, Garcia D N, Silva D A S, Teixeira F R, and Ferraresi V A. Weld Int 32 (2019) 9.

Garcia D N, Mota C A M, and Ferraresi V A, J Braz Soc Mech Sci Eng 41 (2019)

Dodge M F, The Effect of Heat Treatment on the Embrittlement of Dissimilar Welded Joints, Ph.D. Thesis, University of Leicester, England (2014).

Dupont J N, and Kusko C S, Weld J (2007).

ISO 10423, Petroleum and natural gas industries – Drilling and production equipment – Well head and Christmas tree equipment, International Standard (2003).

Gittos M F, and Gooch T G, Br Corr J 31 (1996) 4.

Silva C C, Nickel alloys weld overlays deposited through cold wire GTAW welding process – Operational and metallurgical aspects, Ph.D. Thesis, Federal University of Ceara, Brazil (2010).

Rowe M D, Nelson T W, and Lippold J C, Weld J (1999).

Zhang Q, Tang R, Yin K, Luo X, and Zhang L, Corros Sci 51 (2009) 9.

Doody T, Weld J 71 (1992) 3.

Garcia D N, Ferraresi V A, and Mota C A M, Mater Res 23 (2020) 3.

Acknowledgements

The authors would like to thank the Welding Technologies and Research Study Group (GPTSOLDA) of Federal University of Pará, Brazil, for the laboratorial infrastructure and technical support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mougo, A.L., de Assis Bentes Neto, F.M., Garcia, D.N. et al. Effect of a Cold Wire on the Metallurgical Characteristics of Nickel-Based Welds Deposited by GMAW-CW. Trans Indian Inst Met 73, 2425–2434 (2020). https://doi.org/10.1007/s12666-020-02068-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02068-7