Abstract

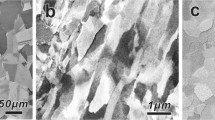

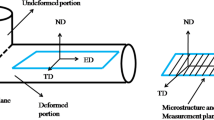

In this study, a new modified cyclic extrusion channel angular pressing (CECAP) process with multi-pass capability is presented for producing ultrafine-grained (UFG) Mg alloy. In this method, an additional extrusion stage with a low extrusion ratio is added at the end of the CECAP process to enhance hydrostatic stresses, equivalent strain, and facilitation of the process implementation. The experimental results showed a remarkable grain refinement with a relatively uniform distribution of microstructure and β-phase in the new CECAP processed sample. The average grain size decreased from ~75 µm in annealed condition to 4.5 µm and 3.5 µm in CECAP and new CECAP processes, respectively. Also, more dispersion of the β-phase with smaller sizes was observed in the processed microstructure. The hardness and its uniform distribution were increased significantly. The compressive yield stress (CYS) was enhanced to about 153.3 MPa from the initial value of ~85 MPa. Also, both the strength and ductility of the new CECAP processed sample were higher than those of CECAP processed one. These excellent properties might attribute to higher hydrostatic compressive stresses resulting from the last low ratio extrusion stage which was almost 50% higher in the new CECAP process.

Similar content being viewed by others

References

Segal V, Reznikov V, Dobryshevshiy A, and Kopylov V, Russ Metall (Metally) 1 (1981) 99.

Segal V, Mater Sci Eng A 197 (1995) 157.

Abdolvand H, Sohrabi H, Faraji G, and Yusof F, Materials Letters 143 (2015) 167.

Gunderov D, Polyakov A, Semenova I, Raab G, Churakova A, Gimaltdinova E, Sabirov I, Segurado J, Sitdikov V, and Alexandrov I, Mater Sci Eng A 562 (2013) 128.

Stepanov N, Kuznetsov A, Salishchev G, Raab G, and Valiev R, Mater Sci Eng A 554 (2012) 105.

Zhang J, Zhang K S, Hwai-Chung W and, Yu M H, Trans Nonferrous Metals Soc China 19 (2009) 1303.

Kim H S, Mater Sci Eng A 430 (2006) 346.

Patil B V, Chakkingal U, and Kumar T P, World Acad Sci Eng Technol 62 (2010) 714.

Faraji G, Mashhadi M M, and Kim H S, Mater Lett 65 (2011) 3009.

Faraji G, Babaei A, Mashhadi M M, and Abrinia K, Mater Lett 77 (2012) 82.

Shen J, Gärtnerová V, Kecskes L J, Kondoh K, Jäger A, and Wei Q, Mater Sci Eng A 669 (2016) 110.

Matsubara K, Miyahara Y, Horita Z, and Langdon T, Acta Materialia 51 (2003) 3073.

Stráská J, Janeček M, Čížek J, Stráský J, and Hadzima B, Mater Charact 94 (2014) 69.

Richert J and Richert M, Aluminium 62 (1986) 604.

Pardis N, Talebanpour B, Ebrahimi R and Zomorodian S, Mater Sci Eng A 528 (2011) 7537.

Amani S, Faraji G, and Abrinia K, J Manuf Process 28 (2017) 197.

Yan Z, Zhang Z, Li X, Xu J, Wang Q, Zhang G, Zheng J, Fan H, Xu K and Zhu J, J Alloys Compd 822 (2020)153698.

Ensafi M, Faraji G, and Abdolvand H, Mater Lett 197 (2017) 12.

Faraji G, and Kim H, Mater Sci Technol 33 (2017) 905.

Nouri M, Semnani H M, and Emadoddin E, Metals Mater Int (2020). https://doi.org/10.1007/s12540-020-00668-y.

Kulagin R, Beygelzimer Y, Estrin Y, Ivanisenko Y, Baretzky B, and Hahn H, Metals 9 (2019) 306.

Ivanisenko Y, Kulagin R, Fedorov V, Mazilkin A, Scherer T, Baretzky B, and Hahn H, Mater Sci Eng A 664 (2016) 247.

Mostaed E, Vedani M, Hashempour M, and Bestetti M, Biomatter 4 (2014) e28283.

Amani S, Faraji G, Mehrabadi H K, Abrinia K, and Ghanbari H, J Alloys Compd 723 (2017) 467.

Witte F, Acta biomaterialia, 6 (2010) 1680.

Poinern G E J, Brundavanam S, Fawcett D, Am J Biomed Eng 2 (2012) 218.

Ge Q, Dellasega D, Demir A G, Vedani M, Acta Biomaterialia 9 (2013) 8604.

Mostaed E, Fabrizi A, Dellasega D, Bonollo F, and Vedani M, J Alloys Compd 638 (2015) 267.

Mehrabadi H K, Faraji G, Amani S, Karimpour M, and Ghanbari H, Modares Mech Eng 16(2016) 605.

Kulyasova O, Islamgaliev R,Mingler B, and Zehetbauer M, Mater Sci Eng A 503 (2009) 176.

Figueiredo R B, and Langdon T G, J Mater Sci 45 (2010) 4827.

Akbaripanah F, Fereshteh-Saniee F, Mahmudi R, and Kim H, Mater Sci Eng A 565 (2013) 308.

Kim W, Hong S, Kim Y, Min S, Jeong H, and Lee J, Acta Materialia 51 (2003) 3293.

Fereshteh‐Saniee F, Akbaripanah F, Kim H, and Mahmudi R, Fatigue Fract Eng Mater Struct 35 (2012) 1167.

Fintová S, Kunz L, J Mech Behav Biomed Mater 42 (2015) 219.

Bettles C, Barnett M, Advances in Wrought Magnesium Alloys: Fundamentals of Processing Properties and Applications, Elsevier, Amsterdam (2012).

Iwahashi Y, Horita Z, Nemoto M, Wang J, and Langdon T G, Scripta Materialia 35 (1996) 143.

Richert M, McQueen H, and Richert J, Can Metalll Q 37 (1998) 449.

Lange K, Handbook of Metal Forming, McGraw-Hill Book Company, NewYork, (1985) p. 1216.

Chalasani D, Jain M K, Shankar S, and Fazeli F, J Mater Eng Perform 28 (2019) 123.

Máthis K, Chmelık F, Trojanová Z, Lukáč P, and Lendvai J, Mater Sci Eng A 387 (2004) 331.

Lichý P, Cagala M, and Beňo J, Mater Technol 47 (2013) 503.

Xu S, Zhao G, Ma X, Ren G, J Mater Process Technol 184 (2007) 209.

Shin D H, Kim I, Kim J, Zhu Y T, Mater Sci Eng A 334 (2002) 239.

Choi Y C, Kim H S, and Hong S I, Metals Mater Int 15 (2009) 733.

Lee K M, Kang H G, Huh M Y, and Engler O, Metals Materials Int 16 (2010) 851.

Chung C, Ding R, Chiu Y, Hodgson M, Gao W, in: IOP Conference Series: Materials Science and Engineering, IOP Publishing, 2009, pp. 012012.

Chung C, Ding R, Chiu Y, Gao W, in: Journal of Physics: Conference Series, IOP Publishing, 2010, pp. 012101.

Chen B, Lin D L, Jin L, Zeng X Q, and Lu C, Mater Sci Eng A 483 (2008) 113.

Shaeri M, Djavanroodi F, Sedighi M, Ahmadi S, Salehi M, and Seyyedein S, J Strain Anal Eng Design 48 (2013) 512.

Ahmadi S, Sedighi M, J Mech Sci Technol 31 (2017) 4189.

Yoon S, Quang P, Hong S, and Kim H, J Mater Process Technol 187 (2007) 46.

Acknowledgments

This work was supported by Iran National Science Foundation (INSF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmadi, S., Alimirzaloo, V., Faraji, G. et al. A New Modified Cyclic Extrusion Channel Angular Pressing (CECAP) Process for Producing Ultrafine-Grained Mg Alloy. Trans Indian Inst Met 73, 2447–2456 (2020). https://doi.org/10.1007/s12666-020-02048-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02048-x