Abstract

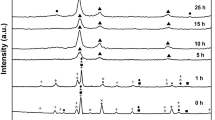

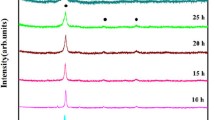

An equiatomic MgAlSiCrFe high-entropy alloy was synthesized by mechanical alloying. The alloying behavior, phase evolution, phase composition and thermal stability of as-milled nanostructured powders of HEA were ascertained through X-ray diffraction and transmission electron microscopy, scanning electron microscopy and differential scanning calorimetry (DSC), respectively. The milling of elemental powders for 60 h led to the formation of HEA with a major BCC phase having lattice parameter of 0.2887 ± 0.005 nm very close to that of the α-Fe and a minor fraction of undissolved Si. The nanocrystalline HEA powder formed during milling has crystallite size of 19 ± 0.8 nm. The STEM–EDS mapping of these milled powders confirms the homogenous elemental distribution after 60 h of mechanical alloying. The DSC thermogram of 60 h milled HEA powder shows the thermal stability of milled powder up to ~ 400 °C. The exothermic heating events observed in the DSC thermogram correspond to phase transformation of MgAlSiCrFe HEA powder, and it may be correlated with the phases observed through the ex situ XRD of HEA powders annealed at different temperatures up to 700 °C. After annealing the 60 h milled powder, various phases along with parent BCC phase have evolved, i.e., B2 type Al–Fe phase, FCC phases (Al–Mg solid solution), Cr5Si3, Mg2Si, Al13Fe4. Further, the experimental findings were correlated with various thermodynamic parameters for understanding the phase evolution and stability.

Similar content being viewed by others

References

Murty B S, Yeh J W, and Ranganathan S, High-Entropy Alloys, 1st edition, Elseveir Inc, New York (2014).

Shechtman D, Blech I, Gratias D, and Cahn J W, Phys Rev Lett 53 (1984) 1951.

Inoue A, Acta Mater 48 (2000) 279. https://doi.org/10.1016/S1359-6454(99)00300-6.

Cantor B, Chang I T H, Knight P, and Vincent A J B, Mater Sci Eng A 375–377 (2004) 213. https://doi.org/10.1016/j.msea.2003.10.257.

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, and Chang S Y, Adv Eng Mater 6 (2004) 299. https://doi.org/10.1002/adem.200300567.

Mukhopadhyay N K, Curr Sci 109 (2015) 665. http://www.jstor.org/stable/24905720.

Gao M C, JOM 67 (2015) 2251. https://doi.org/10.1007/s11837-015-1609-z.

Miracle D B, Mater Sci Technol 31 (2015) 1142. https://doi.org/10.1179/1743284714Y.0000000749.

Miracle D B, and Senkov O N, Acta Mater 122 (2017) 448. https://doi.org/10.1016/j.actamat.2016.08.081.

Miracle D B, Nat Commun 10 (2019) 1. https://doi.org/10.1038/s41467-019-09700-1.

Senkov O N, and Miracle D B, J Alloys Compd 658 (2016) 603. https://doi.org/10.1016/j.jallcom.2015.10.279.

Gorsse S, Miracle D B, and Senkov O N, Acta Mater 135 (2017) 177. https://doi.org/10.1016/j.actamat.2017.06.027.

Steurer W, Mater Charact (2020) 124658. https://doi.org/10.1016/j.colsurfa.2020.124658.

Shivam V, Basu J, Shadangi Y, Singh M K, and Mukhopadhyay N K, J Alloys Compd 757 (2018). https://doi.org/10.1016/j.jallcom.2018.05.057.

Shivam V, Basu J, Pandey V K, Shadangi Y, and Mukhopadhyay N K, Adv Powder Technol 29 (2018). https://doi.org/10.1016/j.apt.2018.06.006.

Shivam V, Shadangi Y, Basu J, and Mukhopadhyay N K, J Mater Res 34 (2019) 787. https://doi.org/10.1557/jmr.2019.5.

Yadav T P, Mukhopadhyay S, Mishra S S, Mukhopadhyay N K, and Srivastava O N, Philos Mag Lett 0839 (2018) 1. https://doi.org/10.1080/09500839.2017.1418539.

Mohanty S, Gurao N P, Padaikathan P, and Biswas K, Mater Charact 129 (2017) 127.

Mohanty S, Gurao N P, and Biswas K, Mater Sci Eng A 617 (2014) 211. https://doi.org/10.1016/j.msea.2014.08.046.

Shivam V, Sanjana V, and Mukhopadhyay N K, Trans Indian Inst Met 73 (2020) 821. https://doi.org/10.1007/s12666-020-01892-1.

Jain H, Shadangi Y, Shivam V, Chakravarty D, Kumar D, Shadangi Y, Shivam V, Chakravarty D, Mukhopadhyay N K, and Kumar D, J. Pre-Proof (2020).

Wang Z, Wu M, Cai Z, Chen S, and Baker I, Intermetallics 75 (2016) 79. https://doi.org/10.1016/j.intermet.2016.06.001.

Shaysultanov D G, Salishchev G A, Ivanisenko Y V, Zherebtsov S V, Tikhonovsky M A, and Stepanov N D, J Alloys Compd 705 (2017) 756. https://doi.org/10.1016/j.jallcom.2017.02.211.

Stepanov N D, Shaysultanov D G, Yurchenko N Y, Zherebtsov S V, Ladygin A N, Salishchev G A, and Tikhonovsky M A, Mater Sci Eng A 636 (2015) 188. https://doi.org/10.1016/j.msea.2015.03.097.

Deng Y, Tasan C C, Pradeep K G, Springer H, Kostka A, and Raabe A, Acta Mater 94 (2015) 124. https://doi.org/10.1016/j.actamat.2015.04.014.

Qiu Y, Hu Y J, Taylor A, Styles M J, Marceau R K W, Ceguerra A V, Gibson M A, Liu Z K, Fraser H L, and Birbilis N, Acta Mater 123 (2017) 115. https://doi.org/10.1016/j.actamat.2016.10.037.

Youssef K M, Zaddach A J, Niu C, Irving D L, and Koch C C, Mater Res Lett 3 (2014) 95. https://doi.org/10.1080/21663831.2014.985855.

Hammond V H, Atwater M A, Darling K A, Nguyen H Q, and Kecskes L J, JOM 66 (2014) 2021. https://doi.org/10.1007/s11837-014-1113-x.

Yang X, Chen S Y, Cotton J D, and Zhang Y, JOM 66 (2014) 2009. https://doi.org/10.1007/s11837-014-1059-z.

Sanchez J M, Vicario I, Albizuri J, Guraya T, and Garcia J C, J Mater Res Technol 8 (2019) 795. https://doi.org/10.1016/j.jmrt.2018.06.010.

Feng R, Gao M C, Zhang C, Guo W, Poplawsky J D, Zhang F, Hawk J A, Neuefeind J C, Ren Y, and Liaw P K, Acta Mater 146 (2018) 280. https://doi.org/10.1016/j.actamat.2017.12.061.

Raabe D, Tasan C C, Springer H, and Bausch M, Steel Res Int 86 (2015) 1127. https://doi.org/10.1002/srin.201500133.

Chen Y L, Tsai C W, Juan C C, Chuang M H, Yeh J W, Chin T S, and Chen S K, J Alloys Compd 506 (2010) 210. https://doi.org/10.1016/j.jallcom.2010.06.179.

Kokai T, Yachu Y, Chienchang J, Tsungshune C, Chewei T, and Jienwei Y E H, Technol Sci 61 (2018) 184.

Murty B S, and Ranganathan S, Int Mater Rev 43 (1998) 101. https://doi.org/10.1179/095066098790105654.

Shadangi Y, Shivam V, Singh M K, Chattopadhyay K, Basu J, and Mukhopadhyay N K, J Alloys Compd 797 (2019) 1280. https://doi.org/10.1016/J.JALLCOM.2019.05.128.

Shadangi Y, Sharma S, Shivam V, Basu J, Chattopadhyay K, Majumdar B, and Mukhopadhyay N K, J Alloys Compd (2020) 154258. https://doi.org/10.1016/J.JALLCOM.2020.154258.

Shadangi Y, Shivam V, Varalakshmi S, Basu J, Majumdar B, Mukhopadhyay N K, Shivam V, Varalakshmi S, Basu J, Chattopadhyay K, and Mukhopadhyay N K, J. Pre-Proof (2020).

Basariya M R, Roy R K, Pramanick A K, Srivastava V C, and Mukhopadhyay N K, Mater Sci Eng A 638 (2015) 282. https://doi.org/10.1016/j.msea.2015.04.076.

Williamson G K, and Hall W H, Acta Metall 1 (1953) 22. https://doi.org/10.1016/0001-6160(53)90006-6.

Yang X, and Zhang Y, Mater Chem Phys (2012). https://doi.org/10.1016/j.matchemphys.2011.11.021.

Miedema A R, de Châtel P F, and de Boer F R, Phys B + C 100 (1980) 1. https://doi.org/10.1016/0378-4363(80)90054-6.

Guo S C T L, Prog Nat Sci Mater Int 21 (2011) 433.

Chen Y L, Hu Y H, Hsieh C A, Yeh J W, and Chen S K, J Alloys Compd 481 (2009) 768. https://doi.org/10.1016/j.jallcom.2009.03.087.

Maulik O, Kumar D, Kumar S, Fabijanic D M, and Kumar V, Intermetallics 77 (2016) 46. https://doi.org/10.1016/j.intermet.2016.07.001.

Maulik O, and Kumar V, Mater Charact 110 (2015) 116. https://doi.org/10.1016/j.matchar.2015.10.025.

Li R, Gao J-C, and Fan K, Mater Sci Forum 686 (2011) 235. https://doi.org/10.4028/www.scientific.net/MSF.686.235.

Acknowledgements

Authors would like to thank Profs. B.N. Sarma, Sandip Chatterjee, K.G. Prashanth, and Dr. Joysurya Basu and Mr. Vikas Shivam for stimulating discussion. Authors would also like to acknowledge the support of Central Instrument Facility, IIT (BHU), and Dr Rampada Manna, Coordinator, Advanced Research Centre for Iron and Steel for extending necessary characterization facility. Authors wish to thank the Department of Science and Technology (DST) for infrastructural support under the scheme “Funds for Improvement of S&T Infrastructure (FIST)” Level-II. Authors thankfully acknowledges technical help of Mr. Lalit Kumar Singh and Girish Sahoo for TEM and SEM investigations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, N., Shadangi, Y. & Mukhopadhyay, N.K. Phase Evolution and Thermal Stability of Low-Density MgAlSiCrFe High-Entropy Alloy Processed Through Mechanical Alloying. Trans Indian Inst Met 73, 2377–2386 (2020). https://doi.org/10.1007/s12666-020-02039-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02039-y