Abstract

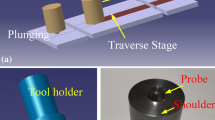

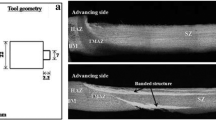

This study explored the role of tool rpm in the microstructure evolution and its significant effect on hardness measurement of friction stir welded 2.25Cr–1Mo (P22) steel to AISI 316LN stainless steel. Irrespective of rotational tool speeds, the martensitic phase transformation was found in the P22 steel side of the dissimilar weldments due to the higher peak temperature, and a higher degree of plastic deformation evolved during friction stir welding. Hardness measurements revealed that the average hardness of the martensitic structure that existed in the friction stir weldment of the P22 steel side is 405 ± 5HV0.2. Evolution of martensitic structure with higher hardness emphasizes that the post-weld heat treatment is mandatory for the dissimilar weldment.

Similar content being viewed by others

References

Sireesha M, Albert S K, and Sundaresan S, Mater Sci Technol19 (2003) 1411.

Venkata K A, Truman C E, Smith D J, and Bhaduri A K, Int J Press Vessels Pip139 (2016) 237.

Akram J, Kalvala P R, Misra M, and Charit I, Mater Sci Eng A688 (2017) 396.

Bhaduri A K, Srinivasan G, Gill T P, and Mannan S L, Int J Press Vessels Pip61 (1995) 25.

Choi D H, Ahn B W, Yeon Y M, and Jung S B, Mater Trans53 (2012) 1022.

Vidyarthy R S, Kulkarni A, and Dwivedi D K, Mater Sci Eng A95 (2017) 249.

Rai R, De A, Bhadeshia H K, and DebRoy T, Sci Technol Weld Join16 (2011) 325.

Sunilkumar D, Muthukumaran S, Vasudevan M, Selvi S P, and Reddy M G, Trans Indian Inst Met72 (2019) 1537.

Kalvala P R, Akram J, Misra M, Ramachandran D, and Gabbita J R, Def Technol12 (2016) 285.

Sunilkumar D, Muthukumaran S, Vasudevan M, and Reddy M G, Sci Technol Weld Join25 (2019) 311.

Mishra R S and Ma Z Y, Mater Sci Eng R Rep50 (2005) 1.

Sudha C, Terrance A L, Albert S K, and Vijayalakshmi M, J Nucl Mater302 (2002)193.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sunilkumar, D., Mathew, J., Muthukumaran, S. et al. Friction Stir Welding of 2.25Cr–1Mo Steel to AISI 316LN Stainless Steel. Trans Indian Inst Met 73, 1689–1693 (2020). https://doi.org/10.1007/s12666-020-01984-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01984-y