Abstract

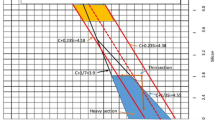

The inoculation process of molten cast iron defines the final microstructure of the produced castings. The current study is concerned with the microstructure and mechanical properties of ductile iron castings as influenced by the type of inoculant. Inoculation treatment was done through one step and double step processes with different types of inoculants. The most efficient inoculant was that containing (1.0% Sr, 0.1% Ca, 0.5% Al) when used in single step or double step with (1.0% Sr, 0.5% Al) containing inoculant. As-cast tensile strength of 580 and 550 MPa at 20 mm thickness was achieved when this inoculant was used in single and double inoculation treatments, respectively. On the other hand, inoculation using the inoculant containing up to 2.0% Ce showed the lowest tensile strength of about 340 MPa. Though the nodule count (at 20 mm) was 100/mm2 for (1.0% Sr, 0.1% Ca, 0.5% Al) inoculant compared to 280/mm2 for the Ce containing inoculants, the pearlite content was higher in case of treatment by the former inoculant which resulted in higher tensile strength.

Similar content being viewed by others

References

Turner T, The Metallurgy of Cast iron, Griffin Co. Ltd., London (1920).

Meehan A, US Patent 1 499 068, (1924).

Fras E, Górny M, Arch Foundry Eng12 (2012) 39.

Riposan L, and Sakaland T, in Cast Iron Science and Technology, (ed) Stefanescu D M, ASM International, 1A (2017).

Regordosa A, and Llorca-Isern N, Int J Metalcast11 (2017) 778.

Popescu M, Zavadil R, and Sahoo M, Int J Metalcast3 (2009) 53.

Riposan L, Chisamera M, and Uta V, Int J Metalcast8 (2014) 65.

Mullins JD, The Most Important Part of Ductile Iron Production-Inoculation, Technical Report, Sorelmetal Technical Service, Rio Tinto Iron Titanium Co. (2006).

Sangame B B, and Shinde V D, IOSR-JMCE5 (2013)17.

Tartaglia J M, and Gundlach R B, Int J Metalcast8 (2014) 7.

Borsato T, Berto F, Ferro P, and Carollo C, Proc Struct Integ2 (2016) 3150.

Cabanne PM, and Gagné M, Inoculation of Ductile Iron; Why and When? Technical Report, Rio Tinto Iron & Iron & Titanium (2010).

Lacaze J, Magnusson L, and Sertucha J, Review of Microstructural Features of Chunky Graphite in Ductile Cast Irons, in Keith Millis Symposium on Ductile Cast Iron, Nashville, USA (2013), p 360.

Pokopec I M, Mrvar P, Bauer B, and Löblich H, Giessereiforschung58 (2006) 28.

Bakkerus H, and Der Holst B V, Mod Cast71 (1981) 41.

Hartung C, White D, and Copi K, Int J Metalcast8 (2014) 7.

Alonso G, Larrañaga P, and Stefanescu D M, Int J Metalcast11 (2017)14.

Rivera G, Boeri R, and Sikora J, J Mater Sci Technol18 (2002) 691.

Riposan L, Chisamera M, and Stan S, China Foundry4 (2007) 300.

Mullins J D, Basic Ductile Iron Alloying, Technical Report, RTIT, Sheet 85 (2003).

Seidu S, and Riposan U P B, Sci Bul73 (2011) 241.

Ferro P, Fabrizi A, Cervo R, and Carollo C, J Mater Process Technol213 (2013) 1601.

Mourad M, El-Hadad S, Ibrahim M, and Nofal A, J Metall (2015) 931535.

Maschke W, and Jonuleit M, Technical Article, https://www.ask-chemicals.com/fileadmin/user_upload/Download_page/professional_articles/EN/Inoculation_of_cast_iron.pdf.

Martin D R, Moreno J R S, and Vicente A A, Acta Sci37 (2015) 355.

Borsato T, Berto F, Ferro P, and Carollo C, Procedia Struct Integr2 (2016) 3150.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mourad, M., El-Hadad, S. & Ibrahim, M. Influence of Inoculant Type on the Microstructure Characteristics and Mechanical Properties of Ductile Iron. Trans Indian Inst Met 73, 1027–1041 (2020). https://doi.org/10.1007/s12666-020-01929-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01929-5