Abstract

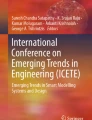

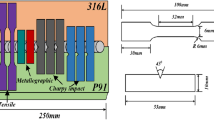

In the present study, low alloy steel AISI 4140 pipe in reheated, quenched and tempered (RQT) condition was friction-welded using 6.4 MPa upset pressure followed by post-weld heat treatment as per the manufacturing practice prevailing in the drill pipe industry and compared the same with friction welds made at different upset pressures in the RQT condition and in the as-received condition to evaluate bond quality. The weld region consisted of a mixture of tempered martensite and ferrite in case of RQT condition and mixture of lath martensite/upper bainite and ferrite in the as-received condition. As the upset pressure was increased, the martensite lath size decreased in both as-received and RQT conditions. In general, as the upset pressure was increased, the average microhardness increased. The average microhardness of the material adjacent to partially deformed zone showed lower hardness due to tempering effect because of weld heat. The upset pressure 6.4 MPa showed better notch tensile strength ratio confirming better ductility of the weld zone. The impact strength decreased as the upset pressure increased in both as-received and RQT conditions. But as-received condition showed significantly lower impact strength due to higher carbide content at the weld interface.

Similar content being viewed by others

References

Kallee S, and Nicholas D, Friction and Forge Welding Processes for the Automotive Industry, SAE Technical Paper (1999) p 99.

Rajamani G P, Shunmugam M S, and Rao K P, Weld J6 (1992) 225.

Reddy D R, Laxminarayana P, Reddy G C M, and Reddy G M S, I J Eng Manuf5 (2016) 38.

Hascalik A, Unal E, and Ozdemir N, J Mater Sci41 (2006) 3233.

Arivazhagan N, Singh S, Prakash S, and Reddy G M, Mater Des32 (2011) 3036.

Chander G S, Reddy G M, and Tagore G R N, Int J Adv Manuf Technol64 (2013) 1445.

Celik S, Ersozlu I, Mater Des30 (2009) 970.

Sutovskii P M, Tkachev Y A, and Semkin N V, Weld Int4 (1990) 734.

Tumuluru M D, Weld J63 (1984) 289.

Emre H E, and Kacar R, Mater Res18 (2015) 503.

Sbalchiero J A, Martinazzi D, Lemos G V B, Reguly A, and Ramos F D, Mater Res21 (2018) 1.

Kimura M, Kusaka M, Kaizu K, Nakata K, and Nagatsuka K, Int J Adv Manuf Technol82 (2016) 489.

Kimura M, Sakaguchi H, Kusaka1 M, Kaizu K, and Takahashi T, Int J Adv Manuf Technol86 (2016) 2603.

Palanivel R, Dinaharan I, and Laubscher R F, Mater Sci Eng A687 (2017) 249.

Palanivel R, Dinaharan I, and Laubscher R F, Optik177 (2019) 102.

Rich T, and Roberts R, Weld J50 (1971) 137.

Meysami A H, Ghasemzadeh R, Seyedein S H, and Aboutalebi M R, Mater Des31 (2010) 1570.

Chuaiphan W, Srijaroenpramong L, and Pinpradub D, Adv Mater Res774 (2013) 1059.

Acknowledgements

The authors would like to express their gratitude to Shri SK. Madar Saheb, Managing Director, Metal Forging Industries, Hyderabad, for extending the facilities. The authors would like to thank Dr. S. Chandra Sekhar, Director of CSIR-Indian Institute of Chemical Technology (IICT/Pubs./2019/399), Hyderabad, for support and Head of the Department of Mechanical Engineering, Osmania University, Hyderabad, for their encouragement to publish the research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khadeer, S.A., Babu, P.R., Kumar, B.R. et al. Influence of Upset Pressure on Microstructure and Mechanical Properties of Friction-Welded AISI 4140 Low Alloy Steel Pipes. Trans Indian Inst Met 73, 465–478 (2020). https://doi.org/10.1007/s12666-019-01858-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01858-y