Abstract

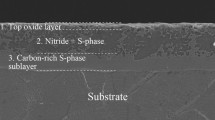

Combined influence of liquid nitriding time and liquid nitriding temperature on the properties of nitrided region developed on 316 stainless steel was investigated. Studies were restricted to low temperatures of 425 °C and 475 °C while the nitriding time was varied from 4 to 16 h. Developed nitrided layers were characterized by optical microscopy, scanning electron microscopy and X-ray diffraction. Mechanical and electrochemical properties of the nitrided layers were characterized, respectively, by Vickers micro-hardness measurements and cyclic polarization studies in 3.5 wt% NaCl solution. After 4-h nitriding at 425 °C or at 475 °C, the developed expanded austenite started to contract with simultaneous decrease in nitrided layer thickness, hardness and corrosion resistance. These prolonged nitriding time effects have been attributed to the decreased chemical potential of nitrogen in salt bath leading to the outward diffusion of N (from sample to salt bath). However, the 4-h nitriding at 475 °C resulted in larger expansion of austenite as compared to 4-h nitriding at 425 °C. Due to this, better mechanical and electrochemical property was realized after 4-h nitriding at 475 °C suggesting that the increased amount of N solubility in sample led to simultaneous increase in hardness and corrosion resistance of stainless steels.

Similar content being viewed by others

References

Bell T, Surf Eng 18 (2003) 415.

De Las Heras E, Egidi D A, Corengia P, González-Santamaría D, García-Luis A, Brizuela M, López G A, and Flores Martinez M, Surf Coat Technol202 (2008) 2945.

Laleh M, Kargar F, and Velashjerdi M J, Mater Eng Perform22 (2013) 130.

Kolotyrkin J M, Corrosion19 (2013) 261.

Zheng Z B, and Zheng Y G, Corros Sci112 (2016) 657.

Thaiwatthana S, Li X Y, Dong H, and Bell T, Surf Eng18 (2002) 140.

Li C X, and Bell T, Corros Sci46 (2004) 1527.

Hashemi B, Rezaeeyazdi M, and Azar V, Mater Des32 (2011) 3287.

Fossati A, Borgioli F, Galvanetto E, and Bacci T, Corros Sci48 (2006) 1513.

Jayalakshmi M, Huilgol P, Bhat B R, and Bhat K U, Mater Des108 (2016)448.

Liang W, Appl Surf Sci211 (2003) 308.

Mingolo N, Tschiptschin A P, and Pinedo C E, Surf Coat Technol201 (2006) 4215.

HoshiyamaY, Mizobata R, and Miyake H, Surf Coat Technol307 (2016) 1041.

Sasidhar, K N, and Meka S R, Acta Materialia161 (2018) 266.

Sasidhar K N, and Meka S R, Scr Mater162 (2019) 118.

Sasidhar K N, and Meka S R, Sci Rep9 (2019) 1.

Zhang Z L, and Bell T, Surf Eng1 1985 131.

Ichii K, Fujimura K, and Takase T, Mater Sci Eng A140 (1991) 442.

Stinville J C, Cormier J, Templier C, and Villechaise P, Mater Sci Eng A605 (2014) 51.

Yu Z, Xu X, Wang L, Qiang J, and Hei Z, Surf Coat Technol153 (2002) 125.

Balachandran G, Bhatia M L, Ballal N B, and Krishna Rao P, Trans Indian Inst Met55 (2002) 149.

Asgari M, Barnoush A, Johnsen R, and Hoel R, Mater Sci Eng A529 (2011) 425.

Christiansen T L, Hummelshøj T S, and Somers M A, Surf Eng26 (2009) 242.

Zhang X, Wang J, Fan H, and Pan D, Appl Surf Sci440 (2018) 755.

Somers M A J, and Christianesen T, Surface Hardening of Stainless Steel, Woodhead Publishing Limited, Cambridge (2015) p. 557.

Easterday J F, and Pilznienski J R, Low Temperature Nitriding Salt and Method of Use, Patent No. US 6 746 546 B2 (2004) p. 1.

Zhang X, Wang J, Fan H, Yan J, Duan L, Gu T, Xian G, Sun L, and Wang D, Metall Mater Trans A49 (2018) 356.

Li L, Wang J, Yan J, Duan L, Li X, and Dong H, Metall Mater Trans A49 (2018) 6521.

Lantelme F, and Henri G, Molten, Elsevier, Amsterdam (2013).

JCPDS. PDF-2 database, Version 2.1. International Center for Diffraction Data (2002).

Christiansen T, and Somers M A J, Metall Mater Trans A37 (2006) 675.

Fonović M, Leineweber A, Robach O, JägleE A, and Mittemeijer E J, Metall Mater Trans A46 (2015) 4115.

Yang W J, Zhang M, Zhao Y H, Shen M L, Lei H, Xu L, Xiao J Q, Gong J, Yu B H, and Sun C, Surf Coat Technol298 (2016) 64.

Borgioli F, Galvanetto E, and Bacci T, Corros Sci136 (2018) 352.

Baba H, Kodama T, and Katada Y, Corros Sci44 (2002), 2393.

Jargelius-Pettersson R F A, Corros Sci41 (1999) 1639.

Newman R C, and Ajjawi M A A, Corros Sci26 (1986) 1057.

Flis-Kabulska I, Sun, Y, and Flis J, Electrochim Acta104 (2013) 208.

Cook A, Padovani C, and Davenport A, J Electrochem Soc164 (2017) C148.

Bandy R, and Van Rooyen D, Corrosion41 (1985) 228.

Saravanan, P, Raja V S, and Mukherjee S, Corros Sci74 (2013) 106.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, N., Chaudhari, G.P. & Meka, S.R. Investigation of Low-Temperature Liquid Nitriding Conditions for 316 Stainless Steel for Improved Mechanical and Corrosion Response. Trans Indian Inst Met 73, 235–242 (2020). https://doi.org/10.1007/s12666-019-01827-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01827-5