Abstract

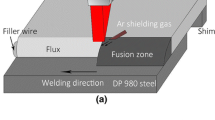

In this study, the experiments of laser weld bonding for DP590 dual-phase steel and 6061 aluminum alloy were carried out. Plasma shape and welding spectra were collected and analyzed, and the effect of adding adhesive layer on the microstructure and mechanical properties of laser-welded joints was also investigated. Some defects, such as pore, crack and softening in heat-affected zone, can be avoided in the weld, the increased weld penetration and width are obtained by adding adhesive layer, and the average tensile–shear strength of joint exceeds than that of no-added joint. In laser weld bonding, the Al content reduces weld penetration depth, but increases both sides of weld, Fe-rich Fe–Al ICMs with better ductility are formed in steel/aluminum interface, the Al diffusion from the lower aluminum to the upper steel side is suppressed, and transverse area of joining steel to aluminum is increased due to increasing Al volume fraction on weld width. In addition, the uniform-sized grains are distributed in the weld, shear load is shared by adhesive layer and weld, and hence, mechanical properties of laser-welded joints are improved.

Similar content being viewed by others

References

Robert W, and Messler J, Ind Robot29 (2012) 138

Liu L M, and Wand H Y, Mater Sci Eng A507 (2009) 22

Liu L M, Wang H Y, and Song G, China Mech Eng18 (2007) 352

Ren D X, and Liu L M, J Mech Eng45 (2009) 266

Wang H Y, Zhang Z D, and Liu L M, Influence of Adhesive During the Heat Transmission of Mg/Al Laser Weld Bonding. Chinese Mechanical Engineering Society and welding Branch. Proceedings of 2008 International Forum on light metal and high strength material welding technology, Mechanic industry Press, Beijing (2008), p 94

Kemal A, Yakup K, and Nizamettin K, Mater Des37 (2012) 356

Yuan W, Shah K, Ghaffari B, and Badarinarayan H, Frict Stir Weld Process3 (2016) 127

Silva D F O, Campilho R D S G, Silva F J G, and Carvalho U T F, Procedia Manuf17 (2018) 705

Wang H Y, Song G, Hou Z L, and Liu L M, Trans Intell Weld Manuf7 (2019) 109

Zhang L J, Zhou D W, and Liu J S, Xu S H, Qiao X J, and Li S, Chin J Nonferr Met23 (2013) 3401

Zuo X R, Zhong Z G, Li L X, Song T F, Weng Y G, and Fang C T, Spec Cast Nonferr Alloys25 (2005) 587

Liu P, Foundry Technol26 (2006) 715

Zhang Z J, Mech Eng Autom6 (2009) 97

Wei J H, Dong J X, Zhang M C, Zeng Y P, and Zhao J C, Ordnance Mater Sci Eng29 (2006) 25

Tan C W, Yang J, Zhao X Y, Zhang K P, Song X G, Chen B, Li L Q, and Feng J C, J Alloys Compd76 (2018) 186

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (51674112 and 51774125) and National Key Research and Development Project of China (2018YFB1107905).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, D., Li, T., Xu, S. et al. Microstructure and Mechanical Properties of Adding Adhesive-Layer Laser-Welded Joints of DP590 Dual-Phase Steel and 6061 Aluminum Alloy. Trans Indian Inst Met 72, 3295–3304 (2019). https://doi.org/10.1007/s12666-019-01799-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01799-6