Abstract

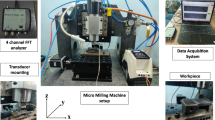

During end milling of metal matrix composite (MMC), it is subjected to varying impact load and cutting force. This action induces vibration during machining, which results in poor surface finish and increased tool wear. In this study, an attempt has been made to determine the optimum level of geometrical parameters such as helix angle, nose radius and rake angle and machining parameters such as cutting speed, feed rate and depth of cut to obtain minimum vibration amplitude during end milling operation using particle swarm optimization (PSO). Machining was carried out on aluminum (Al 356)/silicon carbide (SiC) particulate MMC using high-speed steel end mill cutter. The experimental design adapted for conducting the experiments was L27 orthogonal design array. The experiments were conducted using vertical machining, and the vibration amplitudes were measured at two positions (spindle and workpiece holder) using a twin-channel piezoelectric accelerometer. The empirical regression model was developed by relating the input parameters and the output vibration amplitudes, and optimization of process parameters to obtain minimum acceleration amplitude was done using PSO. Scanning electron microscopic images of the milled surfaces were examined, and it indicated the presence of cracks and holes due to pulling out of SiC particles.

Similar content being viewed by others

References

El-Gallab M, and Sklad M, J Mater Process Technol83 (1998) 151.

Jeyakumar S, Marimuthu K, and Ramachandran T, J Mech Sci Technol27 (2013) 2813.

Ozben T, Kilickap E, and Cakır O, J Mater Process Technol198 (2008) 220.

Seeman M, Ganesan G, Karthikeyan R, and Velayudham A, Int J Adv Manuf Technol48 (2010) (2010) 613.

Premnath A A, Alwarsamy T, and Rajmohan T, Mater Manuf Processes27 (2012) 1035.

Sornakumar T, and Kathiresan M, Int J Min Metall Mater17 (2010) 648.

Ozben T, Kilickap E, and Cakır O, J Mater Process Technol198 (2008) 220.

Bhushan R K, Kumar S, and Das S, Int J Adv Manuf Technol50 (2010) 459.

Dabade U A, Joshi S S, Balasubramaniam R, and Bhanuprasad V V, J Mater Process Technol192 (2007) 66.

Kannan S, and Kishawy H A, J Mater Process Technol198 (2008) 399.

Basheer A C, Dabade U A, Joshi S S, Bhanuprasad V V, and Gadre V M, J Mater Process Technol197(1) (2008) 439.

Subramanian M, Sakthivel M, Sooryaprakash K, and Sudhakaran R, Measurement46 (2013) 4005.

Karabulut Ş, Measurement66 (2015) 139149.

Weinert K, Kersting P, Surmann T, and Biermann D, Prod Eng2 (2008) 255.

Arokiadass R, Palaniradja K, and Alagumoorthi N, Trans Nonferrous Met Soc China22 (2012) 1568.

Zhang J Z, and Chen J C, Int J Adv Manuf Technol39 (2008) 118.

Sivasakthivel P S, Sudhakaran R, and Rajeswari S, Proc Inst Mech Eng Part B J Eng Manuf227 (2013) 1788.

Sivasakthivel P S, Velmurugan V, and Sudhakaran R, Int J Adv Manuf Technol53 (2011) 453.

Wang Z G, Rahman M, Wong Y S, and Sun J, Int J Mach Tools Manuf45 (2005) 1726.

Saravanan R S R S, Siva Sankar R, Asokan P, Vijayakumar K, and Prabhaharan G, Int J Adv Manuf Technol26 (2005) 30.

Palanisamy P, Rajendran I, and Shanmugasundaram S, Int J Mach Machinability Mater1 (2006) 233.

Ozcelik B, Oktem H, and Kurtaran H, Int J Adv Manuf Technol27 (2005) 234.

Baskar N, Asokan P, Prabhaharan G, and Saravanan R, Int J Adv Manuf Technol25 (2005) 1078.

Yusup N, Zain A M, and Hashim S Z M, Procedia Eng29 (2012) 914.

Shirvanimoghaddam K, Khayyam H, Abdizadeh H, Karbalaei Akbari M, Pakseresh A H, Ghasali E, and Naebe M, Mater Sci Eng A658 (2016) 135.

Peace G S, Taguchi Methods, A Hands-on Approach. Addison-Wesley, Reading, MA (1992).

Modares H, Alfi A, and Sistani M B N, Eng Appl Artif Intell23 (2010) 1105.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sridhar, R., Perumal Subramaniyan, S. & Ramesh, S. Optimization of Machining and Geometrical Parameters to Reduce Vibration While Milling Metal Matrix Composite. Trans Indian Inst Met 72, 3179–3189 (2019). https://doi.org/10.1007/s12666-019-01783-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01783-0